Aluminum foil for high-extension high-deep-drawing-power aluminum-plastic film and production process of aluminum foil

A production process, aluminum-plastic film technology, applied in metal rolling and other directions, can solve problems such as elongation rate can only reach 18%, product stability is not easy to ensure, trimming cracks and burrs, etc. The effect of cutting edge quality is not easy to guarantee, stability is not easy to be guaranteed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The present invention will be described in detail below by way of a particular embodiment in order to further explain the present invention.

[0073] The present invention discloses a production process of aluminum foil for high-profile high-punching power aluminum-plastic film, which mainly includes the steps of:

[0074] A production process of aluminum foil for high-intensity extension, high-punch-cutting power aluminum film, includes the following steps:

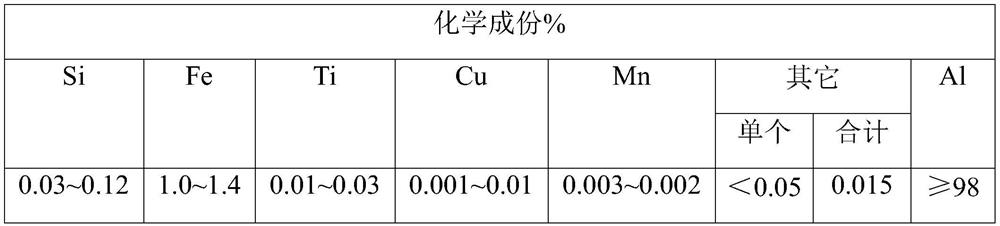

[0075] A. Take

[0076] The following chemical composition percentage of raw material alloy is placed into the smelting furnace for smelting, and the specific chemical composition table is as follows:

[0077]

[0078] Since the power aluminum plastic film product is high, the stability is high, so considering that the control range of major alloy elements is further narrowed under the original conditions, it is advantageous to improve the stability of the aluminum foil product. The lifting FE content is advantageou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com