Zinc-nickel alloy plating solution and plating method

A zinc-nickel alloy and plating solution technology, applied in the field of acid zinc-nickel alloy plating solution, can solve the problem of no carbonate accumulation and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

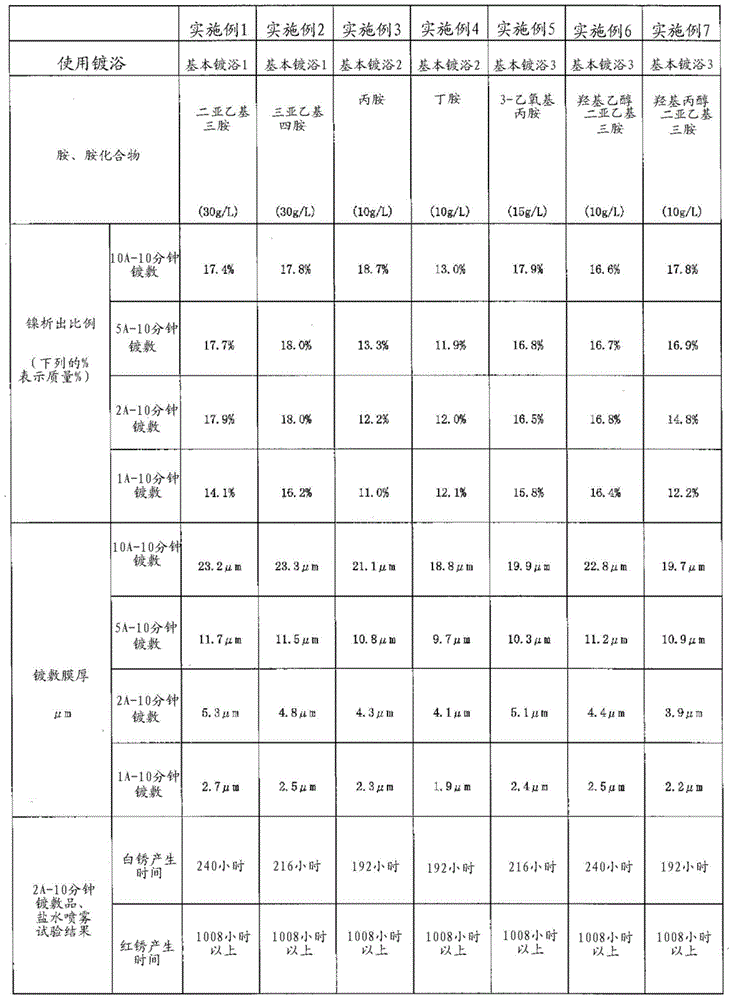

[0085] Hereinafter, examples for demonstrating the effects of the present invention will be described in detail.

[0086] 1.Basic plating bath and alkaline plating bath for comparison

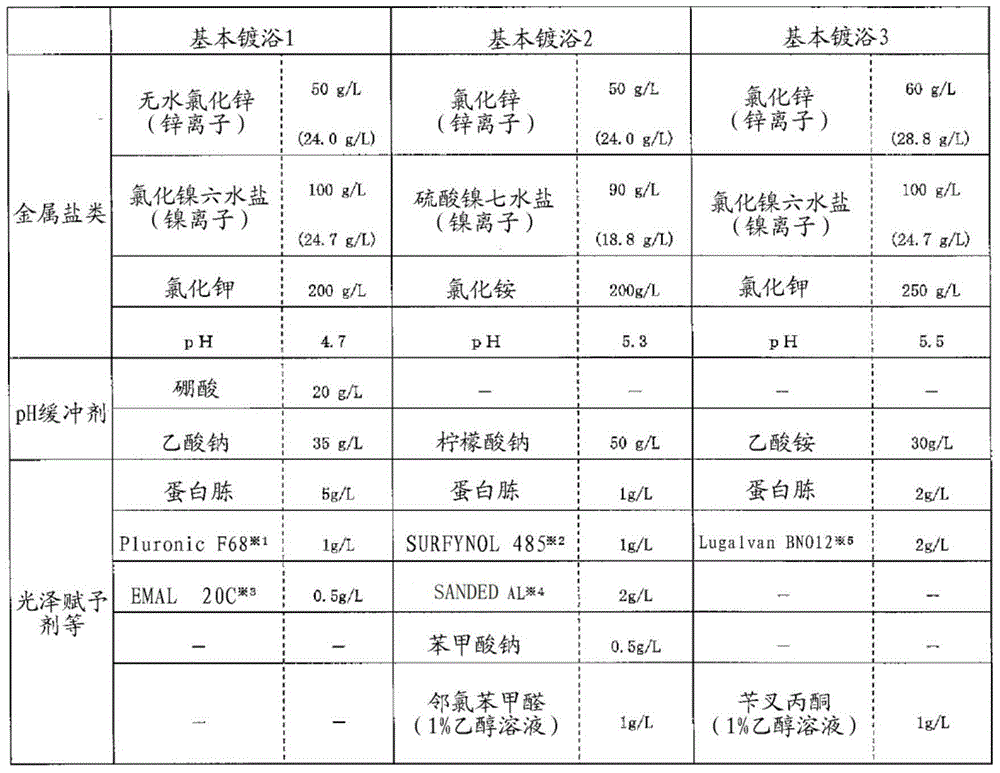

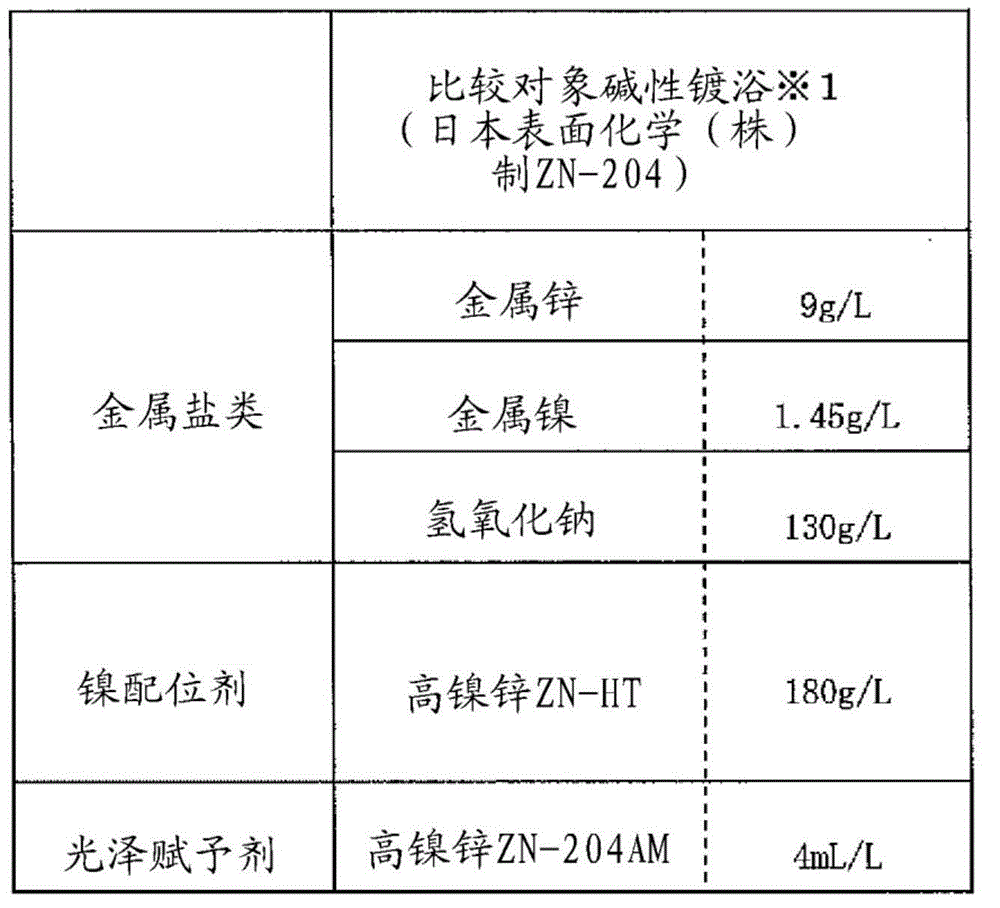

[0087] The basic plating bath and the alkaline plating bath for comparison objects of the composition described in the following Table 1 and Table 2 were prepared. Materials to which predetermined amounts of each amine compound were added (or materials not added) were used as Examples 1-7 and Comparative Examples 1-4.

[0088] [Table 1]

[0089]

[0090] Pluronic F68*1: ADEKA Co., Ltd., PEG / PPG-160 / 30 copolymer

[0091] SURFYNOL485*2: Acetylene glycol EO adduct manufactured by AIR PRODUCTS

[0092] EMAL20C*3: manufactured by Kao Corporation, sodium lauryl polyoxyethylene sulfate

[0093] SANDEDAL*4 (Sanded AL*4): Sanyo Chemical Co., Ltd., sodium alkyl diphenyl ether disulfonate

[0094] LugalvanBNO12*5: Made by BASF Corporation, EO adduct of β-naphthol (EO, 12 moles)

[0095] [Table ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com