Steel plate for low-temperature pressure container and manufacturing method thereof

A technology for a pressure vessel and a manufacturing method, which is applied to the steel plate for low-temperature pressure vessel and its manufacturing field, can solve the problems of insufficiency, increased cost, difficult heating and rolling process, etc., and achieves low production cost, improved technical level, and improved transportation efficiency. and economic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

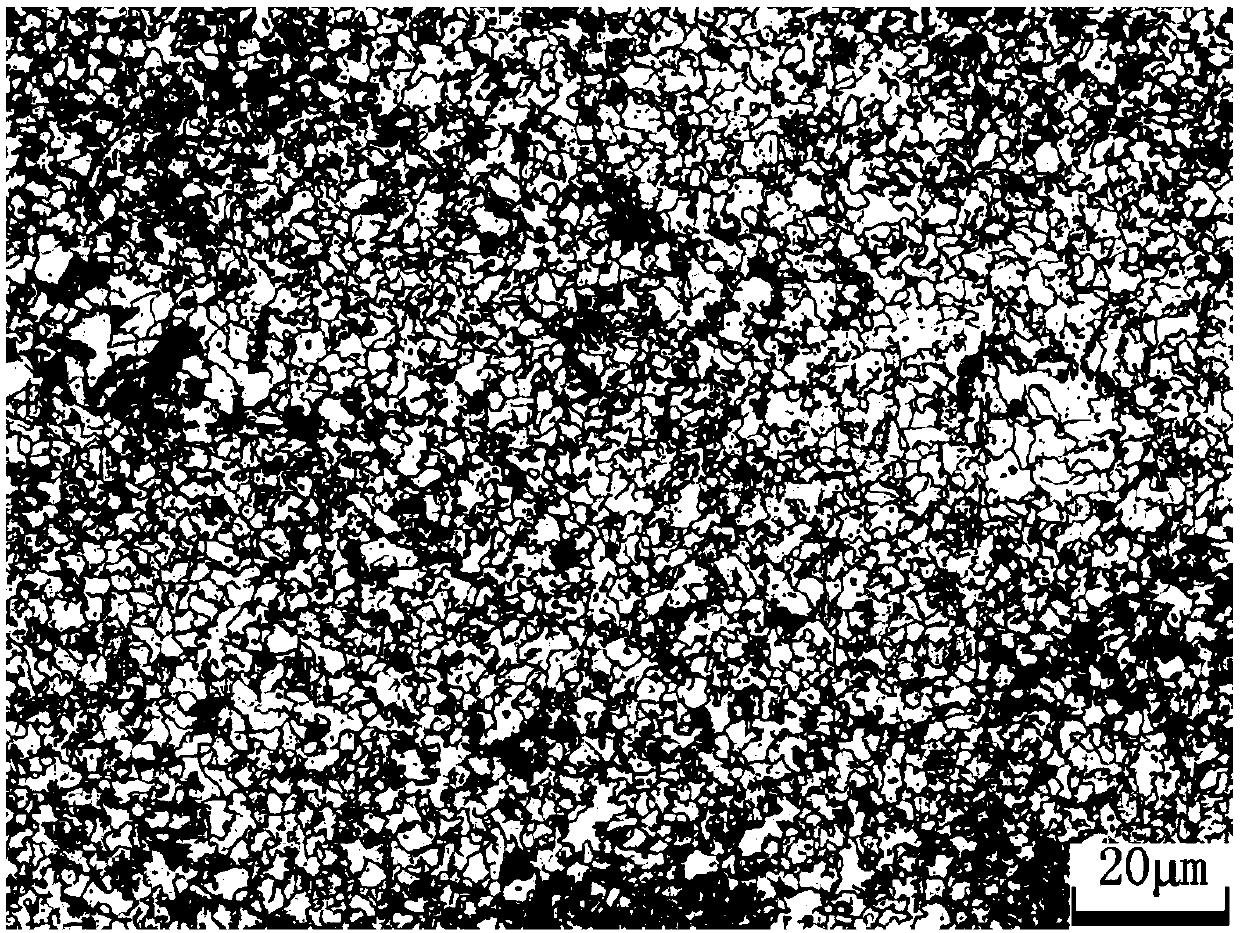

Image

Examples

Embodiment 1~7

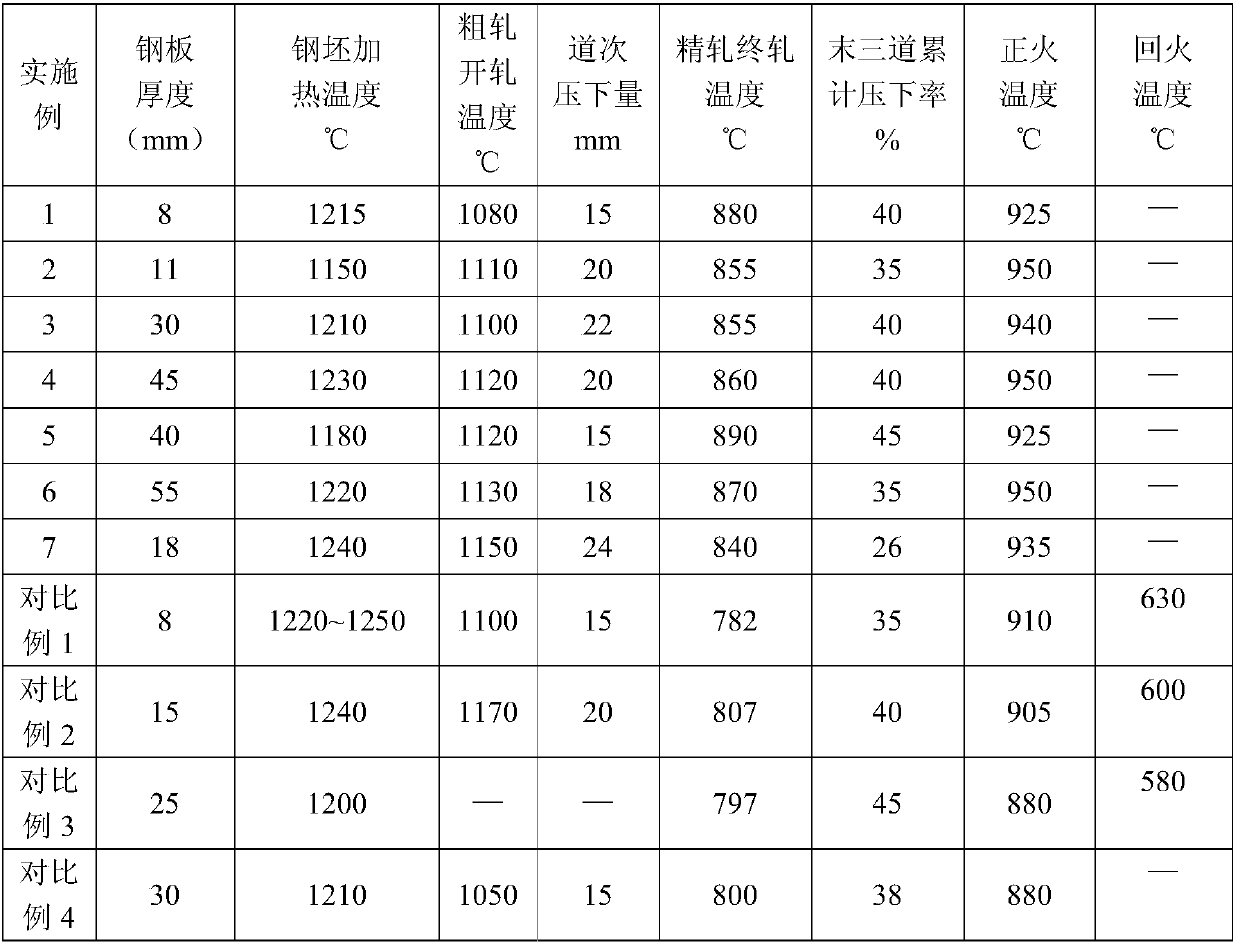

[0036] Examples 1-7 all produced steel according to the following steps:

[0037] 1) Through converter smelting to realize vanadium microalloying, blowing nitrogen at the bottom of the ladle furnace to heat up, vacuum to remove gas inclusions and control the level of N content in steel to achieve vanadium-nitrogen microalloying. After continuous casting, the billet is heated and controlled The heating temperature is 1170~1260℃, and the heating rate is controlled at 8~14min / cm;

[0038] 2) For hot rolling, control the start-rolling temperature to be no less than 1070°C, control the cumulative reduction of the last three passes to be no less than 30%; control the final rolling temperature to be no less than 860°C;

[0039] 3) The normalizing process is used for heat treatment, the normalizing temperature is controlled at 920~960℃, and the heat preservation time: 30~40 minutes + plate thickness in millimeters × 1 minute / mm.

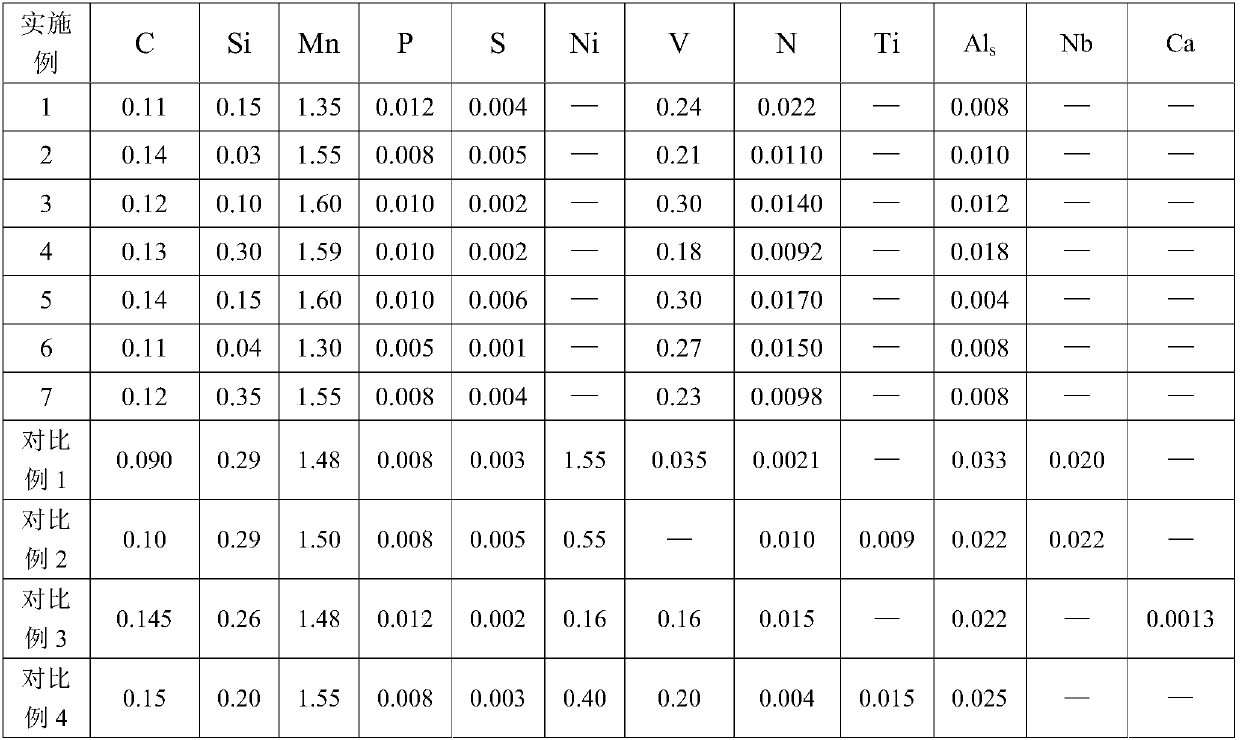

[0040] Among them, Table 1 shows the chemical composition valu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com