A composite inoculant for microstructure refinement of high-damping zinc-aluminum alloy

A composite inoculant, zinc-aluminum alloy technology, which is applied in the field of /Al composite inoculant for high damping zinc-aluminum alloy microstructure refinement, can solve the problems of high cost, complicated process and operation, and high energy consumption.

Active Publication Date: 2022-05-31

HEBEI UNIV OF TECH

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

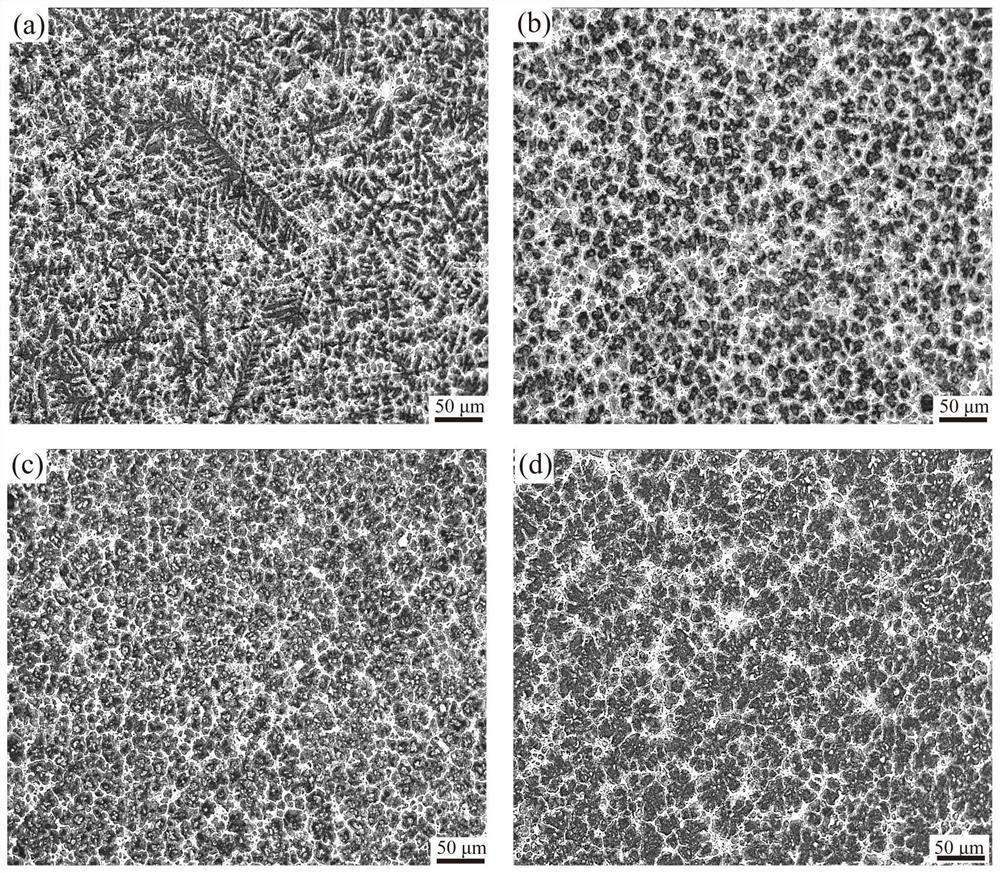

CN102978425A and CN102268573A disclose two refiners that can be used for zinc-aluminum alloys, which can refine the grains of the alloy to about 50 μm, but the degree of grain refinement is still not enough

Although the technology disclosed in CN106756156A can refine the crystal grains of zinc-aluminum eutectoid alloy (ZA22) to 10-12 μm, this technology needs to carry out vacuum stripping rapid solidification treatment and compound addition of Zr element to the inoculant to realize, not only the process The operation is relatively complicated, and the cost is high and the energy consumption is large. In addition, the improvement of the mechanical properties of the refined ZA22 alloy using this technology is also relatively limited.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Login to View More

Abstract

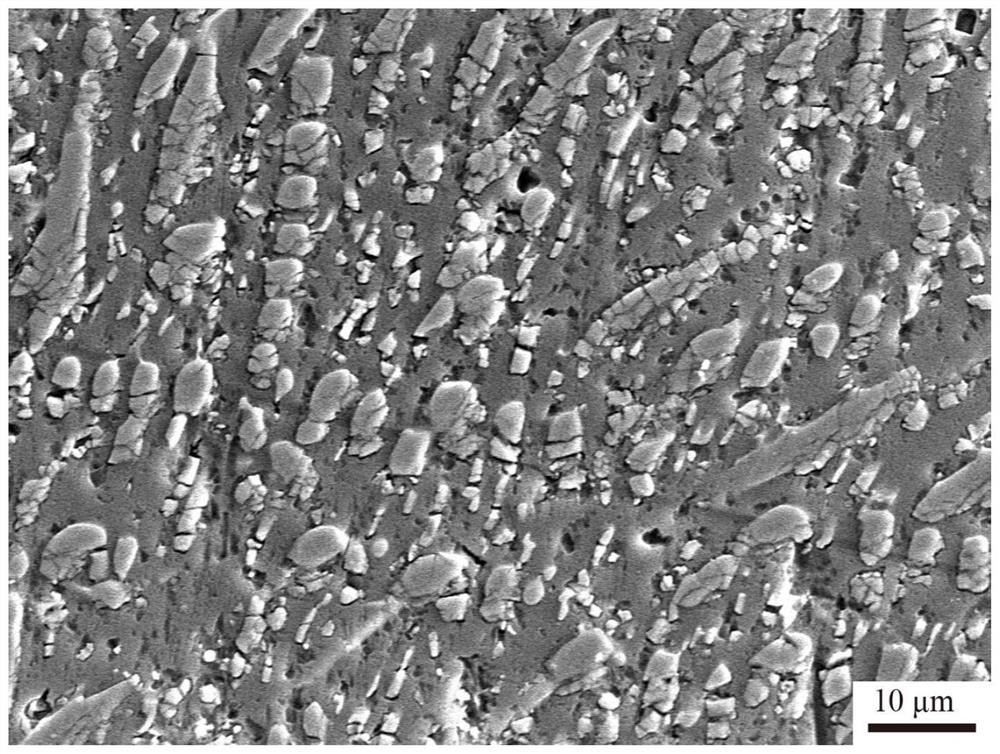

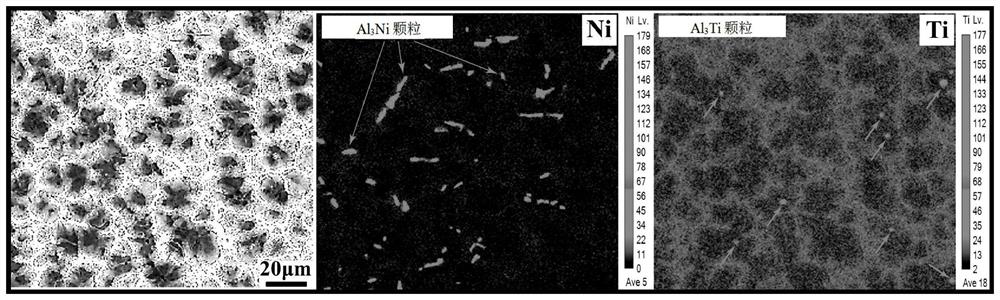

The invention relates to a composite inoculant for refining the microstructure of high-damping zinc-aluminum alloys. The mass percent content of each element in the inoculant is: Ni is 18-23%, Ti is 4-6%, and the rest is Al; Ni and Ti react with Al in situ to form Al 3 Ni,Al 3 Ti two kinds of particles. The Al 3 Ni,Al 3 The size of the Ti particles ranges from submicron to micron. The composite inoculant of the present invention can effectively refine the structure of zinc-aluminum alloy, and can significantly improve the strength, plasticity and damping performance of the refined zinc-aluminum alloy, and overcome the insufficient refinement degree of zinc-aluminum alloy by existing refiners , The preparation process of the inoculant is complicated, and the mechanical properties of the refined zinc-aluminum alloy are limited.

Description

A composite inoculant for high damping zinc-aluminum alloy microstructure refinement technical field Technical scheme of the present invention relates to aluminum-based composite material, specifically a kind of high damping zinc-aluminum alloy microstructure refinement used (Al 3 Ni+Al 3 Ti) / Al composite inoculant. Background technique In recent years, the rapid development of modern industrial technology has made a large number of high-precision, high-power construction machinery and equipment [0002] came into being. While they bring benefits to the development of society, military and national defense, they also bring serious vibration and sound polution. Vibration and noise will not only damage the working environment of people and machines, making the human body prone to fatigue and illness, but also make machinery The working efficiency of the equipment is reduced and the service life is shortened. In the military field, the vibration and noise of we...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C22C21/00C22C1/02C22C1/03C22C18/04

CPCC22C21/00C22C1/026C22C1/03C22C18/04Y02P10/20

Inventor 王清周张建军殷福星余晖冀璞光焦志娴刘力

Owner HEBEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com