Composite inoculant for refining high-damping zinc-aluminum alloy structure

A composite inoculant, zinc-aluminum alloy technology, applied in the field of high-damping zinc-aluminum alloy structure refinement/Al composite inoculant, can solve the limited improvement of the mechanical properties of the ZA22 alloy, insufficient grain refinement, and energy consumption. Can big and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

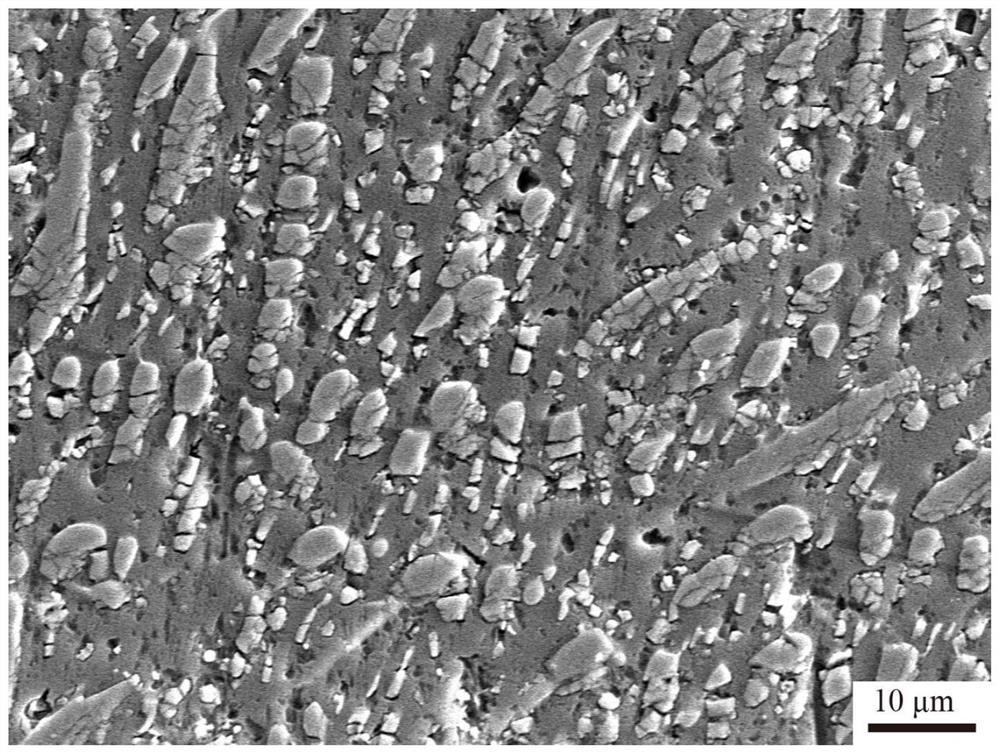

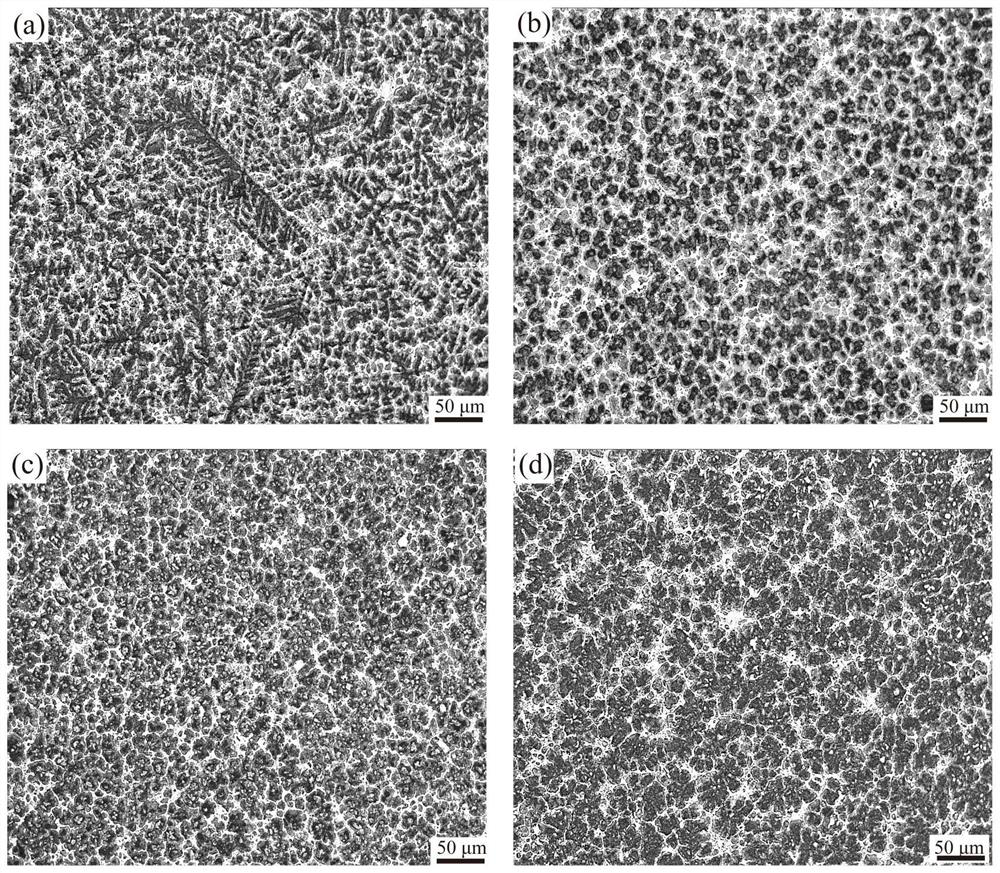

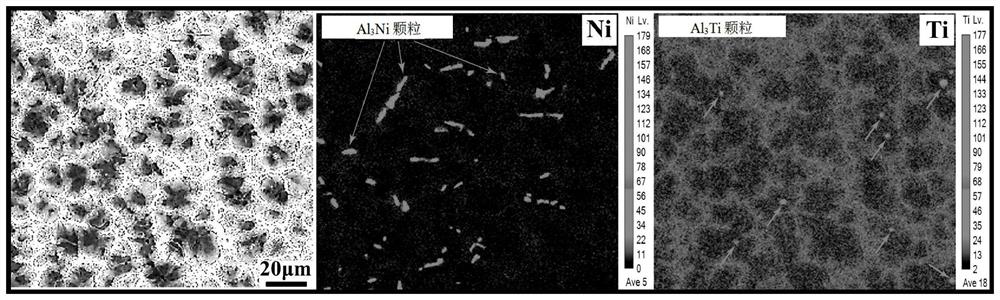

Embodiment 1

[0034] Pure Al, pure Ni metal is cut into 6 × 6 × 6mm 3 After the square, it was polished with water sandpaper, then pure Al, pure Ni metal block and sponge Ti were placed in anhydrous ethanol to clean 8 min, then put it in a vacuum drying box, after 15min at 60 ° C for 15 minutes, press NI. The mass content of 18 wt.%, Ti has a mass content of 4 wt.%, The rest is Al, weighs a total mass of 10 g and put it into the copper crucible of the micro-arc furnace, and then adjusts the electrode. The position between the positions between the raw materials in the crucible is 1.5mm, and the furnace door, the inlet and the deflation valve are closed, and the furnace cavity is vacuumped to reduce the air pressure to 1.2 × 10 -3 PA, subsequently charged into high purity argon to raise the furnace air pressure to 0.03Pa, then evacuate it again, so that the arc is started after three times, and the current is gradually increased, until the current value reaches 160A, here After the current value...

Embodiment 2

[0036] Pure Al, pure Ni metal is cut into 6 × 6 × 6mm 3 After the square, it was polished with water sandpaper, and then pure Al, pure Ni metal block and sponge Ti were placed in anhydrous ethanol to clean 10 min, and then put it in a vacuum drying box, after drying at 80 ° C for 14 minutes, press NI. The mass percentage of 20 wt.%, Ti has a mass percentage of 5 wt.%, The rest is Al, weighs a total mass of 12 g and places it into the copper crucible of the micro-arc furnace, and then adjusts the electrode. The position is 2mm between the pitch between the raw materials in the crucible, sequentially close the furnace door, the inlet and the deflation valve proceeds to the furnace cavity, so that the air pressure drops to 1.5 × 10 -3 PA, then charged into high purity argon to raise the furnace cavity to 0.05Pa, then evacuate it again, so that the arc is started after 4 times, and the current is gradually increased, until the current value reaches 170A, here After the current value i...

Embodiment 3

[0038] Pure Al, pure Ni metal is cut into 6 × 6 × 6mm 3 After the square, it was polished with water sandpaper, and then pure Al, pure Ni metal block and sponge Ti were placed in anhydrous ethanol to clean 12 minutes, then put it in a vacuum drying tank, dried at 100 ° C for 12 minutes and pressed according to Ni. The mass percentage of 23 wt.%, Ti has a mass percentage of 6 wt.%, The rest is Al, weighs a material having a total mass of 15 g and places it into the copper crucible of the micro-arc furnace, and then regulates the electrode. The position is 2.5 mm between the raw materials in the crucible, and then close the furnace door, the inlet and the deflation valve, so that the furnace cavity is vacuum-processed, so that the air pressure drops to 1.5 × 10 -3 PA, subsequently charged into high purity argon to raise the furnace air pressure to 0.07Pa, then evacuate it again, so that the arc is started after 4 times, and the current is gradually increased, until the current value...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com