Backwashing filter

A filter and backwashing technology, which is applied in the direction of fixed filter elements, filter separation, chemical instruments and methods, etc., can solve the problems of cumbersome cleaning process, affecting work efficiency, affecting filtering effect, etc., and achieves simple and powerful cleaning. Strong, excellent cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

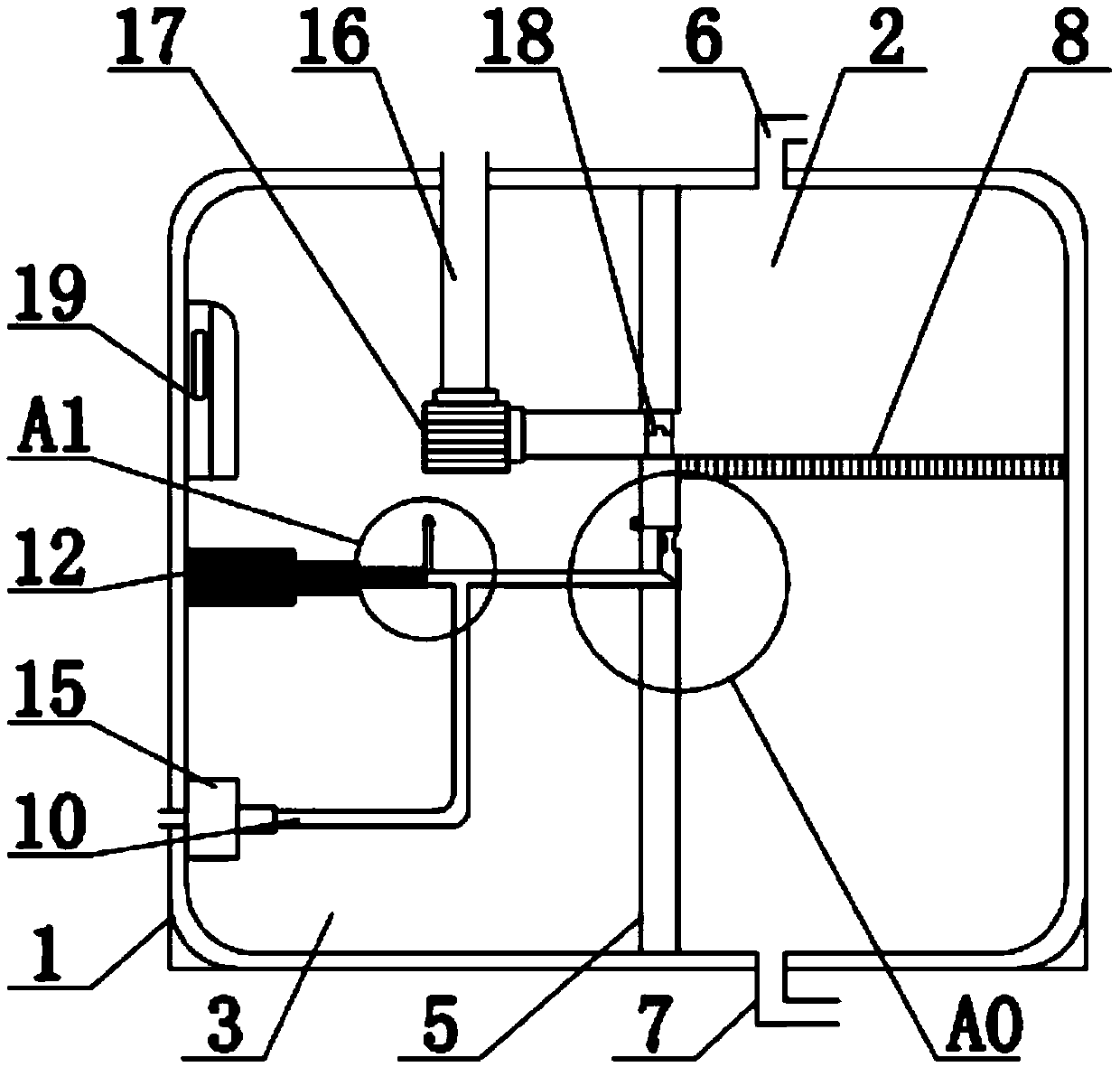

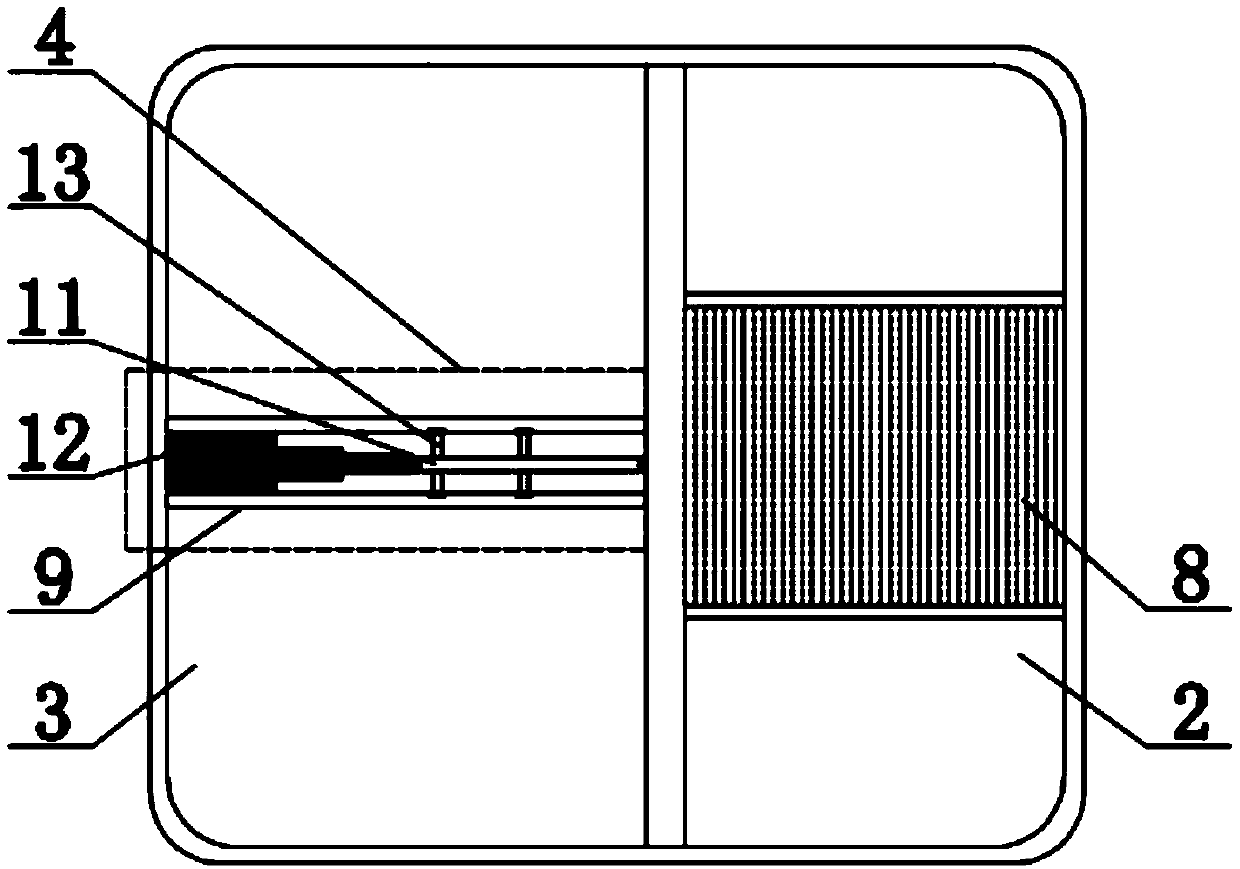

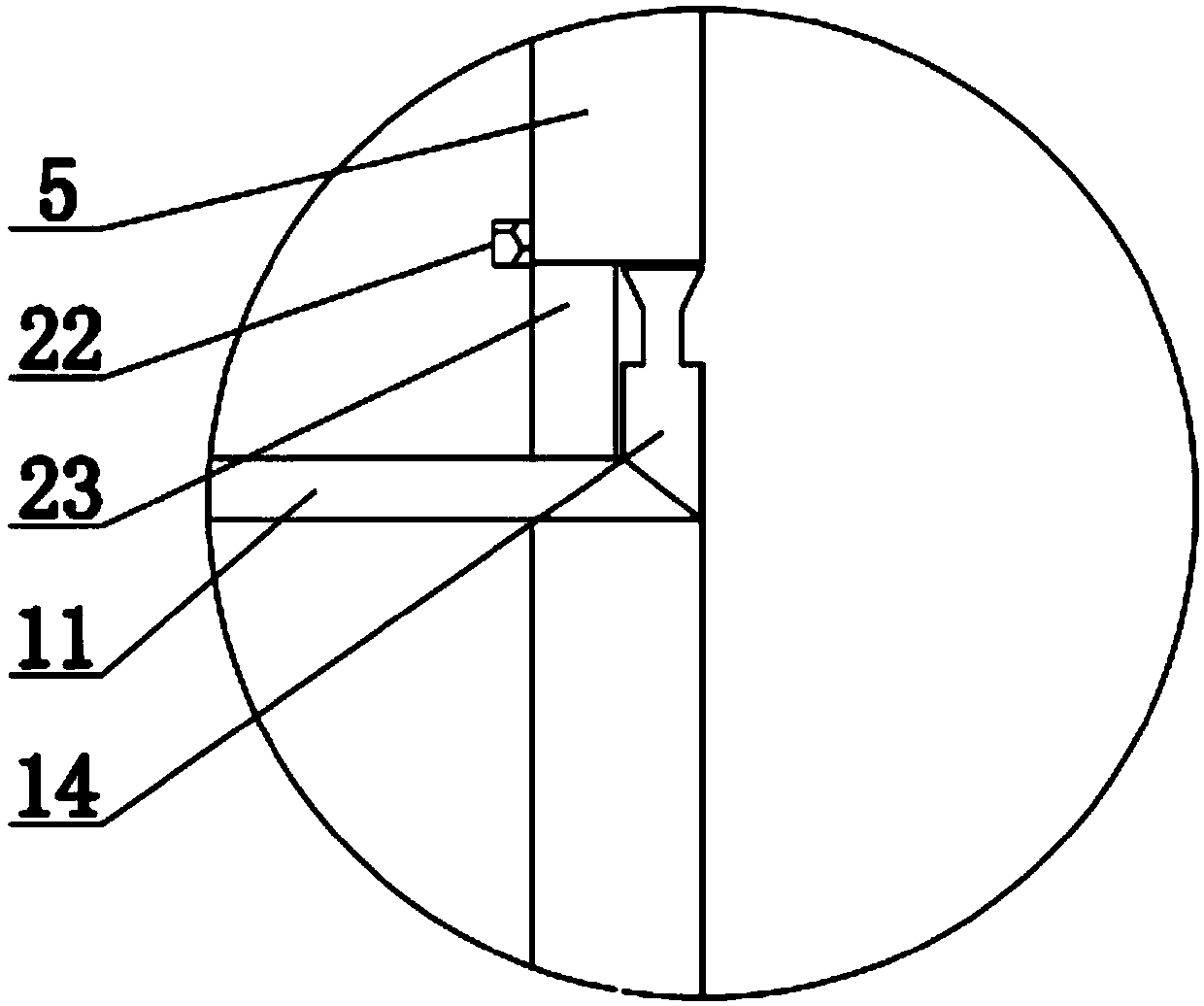

[0024] see figure 1 —4, a backwash filter, including a device housing 1, a filter chamber 2, a flushing chamber 3, and a flushing assembly 4. The interior of the device housing 1 is fixedly connected with a partition 5, and the two sides of the partition 5 are filter The cavity 2 and the flushing cavity 3, the top and the bottom of the filtering cavity 2 are respectively fixedly connected with a water inlet 6 and a water outlet 7, the inside of the filtering cavity 2 is provided with a filter screen 8, and the corresponding two sides of the flushing cavity 3 are The sliding groove 9 is fixedly connected and the two groups of sliding grooves 9 are symmetrical to each other. The sliding groove 9 is located at the lower part of the filter screen 8 relative to the filter screen 8. A flushing assembly 4 is arranged in the sliding groove 9; the flushing assembly 4 includes a flushing pipeline 10 and a flushing head 11. 1. Telescopic rod 12, the inside of the flushing chamber 3 is lo...

Embodiment 2

[0027] see figure 1 -4, the working principle of the present invention is: when in use, the required filtered water flows in through the water inlet 6, and after being filtered by the filter screen 8, it flows out through the water outlet 7;

[0028] When the filter screen 8 needs to be cleaned, the PLC controller 19 is controlled by the control button on the console, and the PLC controller 19 can control the telescopic rod 12 so that the telescopic rod 12 stretches out, and the stretched telescopic rod 12 will drive the flushing head connected to it 11. Make the flushing head 11 slide out on the sliding groove 9 through the sliding block 13. When the telescopic rod 12 stretches out until the limit sensor 21 senses the limit block 22, the sensor sends information back to the PLC controller 19 to make it control The telescopic rod 12 is retracted, and the preset PLC control program in the PLC controller 19 will make the telescopic rod 12 reciprocate. Finally, the filter screen...

Embodiment 3

[0030] see figure 1 —4, both sides of the filter cavity 2 can be provided with a flushing cavity 3 and the structure of the installation parts is the same; the upper part of the nozzle 14 is evenly arranged with multiple groups of round holes, and the nozzle 14 can be provided with multiple groups of round holes on the upper part of each group of nozzle 14 The diameters are different; the telescopic rod 12 is provided with a protective housing, and the two sides of the protective housing are fixedly connected with fixed brackets; the lower pressing plate 23 provided at the opening is connected by a hinge, and when the hinge is used, the flushing head 11 passes through the lower part of the lower pressing plate 23 and the area formed between the openings.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com