A kind of fast descaling anti-corrosion and environment-friendly descaling agent and its preparation method and application

A descaling agent and an environment-friendly technology, applied in the field of anti-corrosion and environment-friendly descaling agent and its preparation, can solve the problems of low efficiency and long descaling time, and achieve the effect of promoting uniform dispersion and suspension, high-efficiency descaling, and avoiding the need for repeated descaling. effect of precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A kind of rapid descaling anti-corrosion environmental protection descaling agent, the preparation formula and ratio are: oxalic acid Kg, citric acid 2Kg, malic acid 3Kg, tannic acid 2Kg, sodium polyacrylate 2Kg, dispersant 0.05Kg, sodium hexametaphosphate 10Kg, deionized water 50Kg; wherein, the dispersant is potassium sorbate, benzoic acid, propionic acid in a mass ratio of 1:0.5:2.5 mixed.

[0055] Among them, the sources of different raw materials can be described as follows: sodium polyacrylate was purchased from Henan Zhenya Chemical Products Co., Ltd., and its relative molecular weight is 2000-5000 low molecular weight sodium polyacrylate, industrial grade, model 445N, the goods number is 20181213; the CAS number of oxalic acid is 144-62-7, which is industrial grade, purchased from Jinan Dehou Chemical Co., Ltd.; the CAS number of citric acid is 5949-29-1, which is industrial grade, purchased from Jinan Yuanfei Weiye Chemical Co., Ltd The CAS number of malic acid is ...

Embodiment 2-14

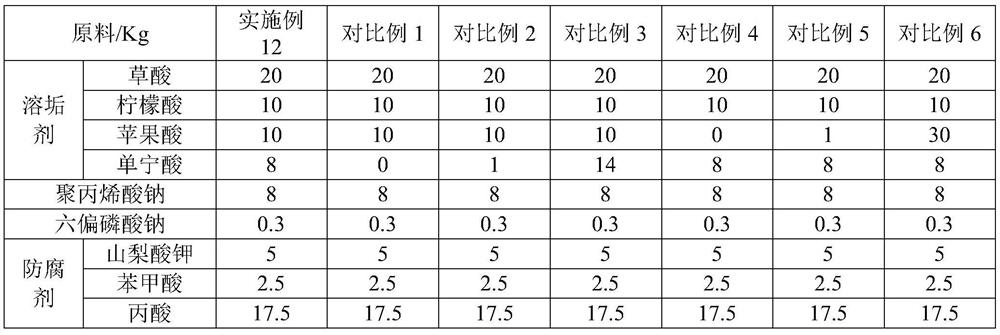

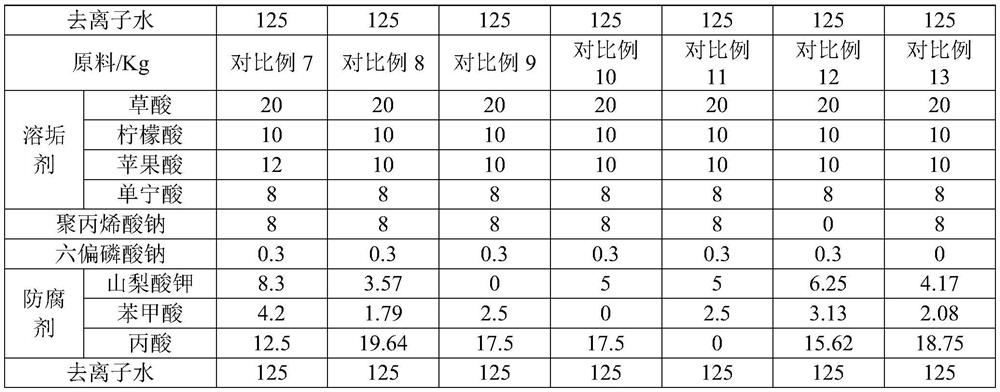

[0062] Example 2-14 of the rapid descaling of the anti-corrosion environmental protection descaler formulation ratio and Example 1 is different, specifically referred to In Table 1, a rapid descaling anti-corrosion environmental protection descaling agent preparation method with Example 1.

[0063] Table 1 Embodiment 1 of the descaler formulation ratio

[0064]

Embodiment 15

[0066] The difference between Example 15 and Example 12 is: a method for preparing a rapid descaling anti-corrosion environmental protection descaler, comprising the following steps:

[0067] S1 Oxalic acid, citric acid, tannic acid and malic acid are crushed and then screened over 700 mesh and set aside;

[0068] S2 mixed the oxalic acid, citric acid, tanninic acid and malic acid and deionized water obtained in S1 for 20 min to give solution A;

[0069] S3 added sodium polyacrylate to solution A, heated to 90 ° C and stirred for 40min, then cooled to room temperature to give solution B;

[0070] S4 in solution B of S3 was added to sodium hexametaphosphate, potassium sorbate, benzoic acid, propionic acid, stirred and mixed.

[0071] Otherwise with Example 12.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com