Descaling device at inner wall of steel tube with 20-100mm of diameter

A technology for the inner wall of a steel pipe and a descaling device, which is applied in the direction of the abrasive material feeding device, explosion generating device, abrasive material, etc., can solve the problems of unproposed technology and equipment, and cannot be processed, and achieves low descaling cost and simple structure , The effect of easy operation of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

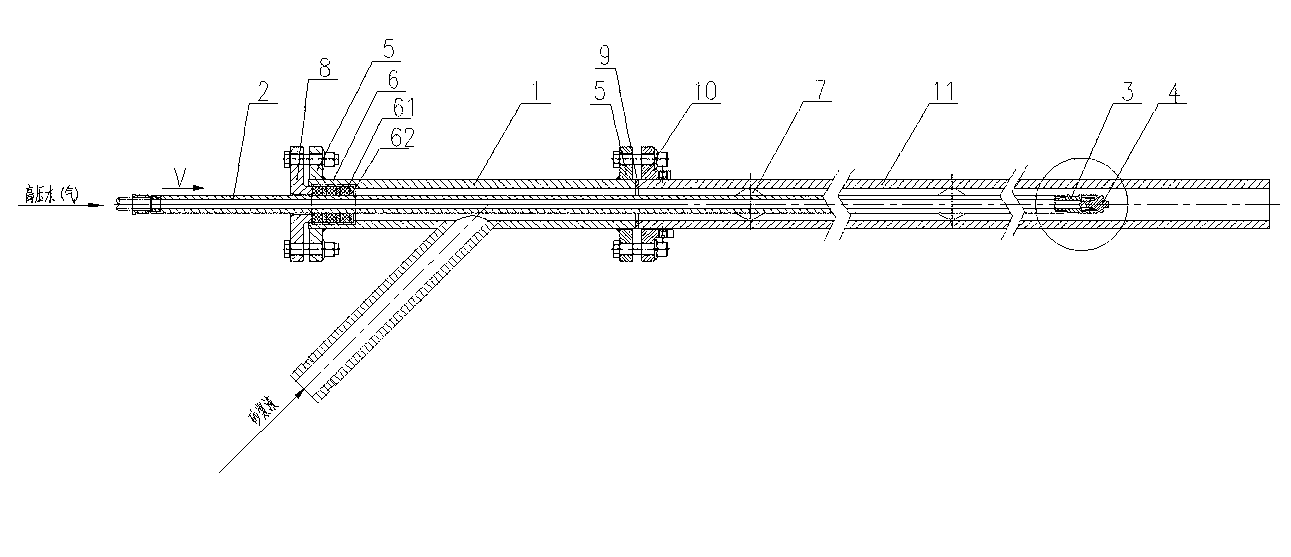

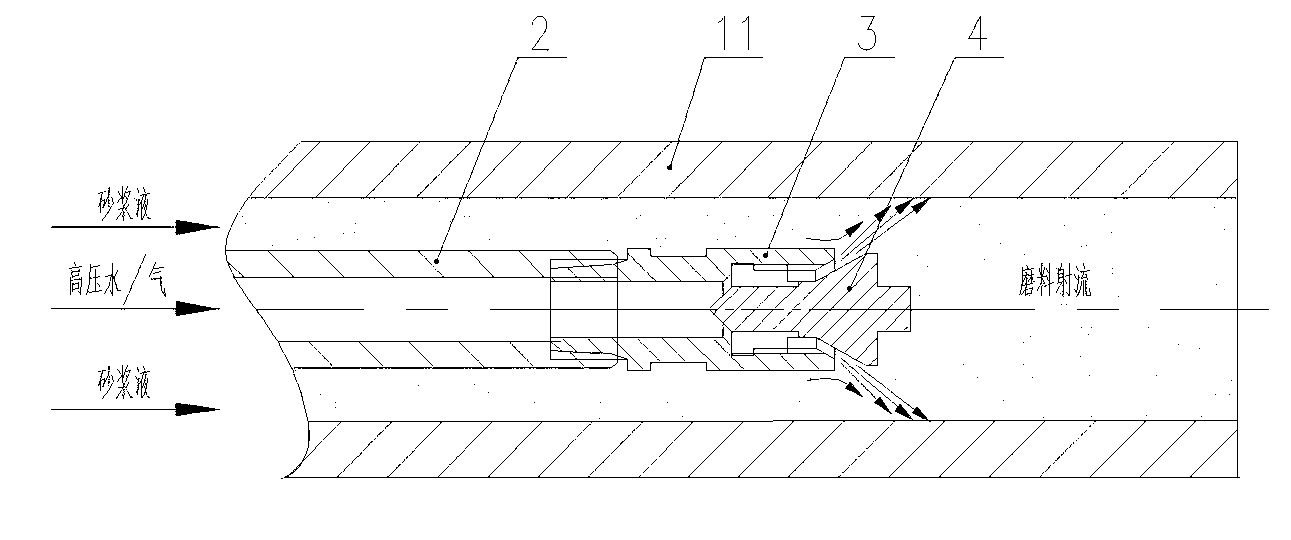

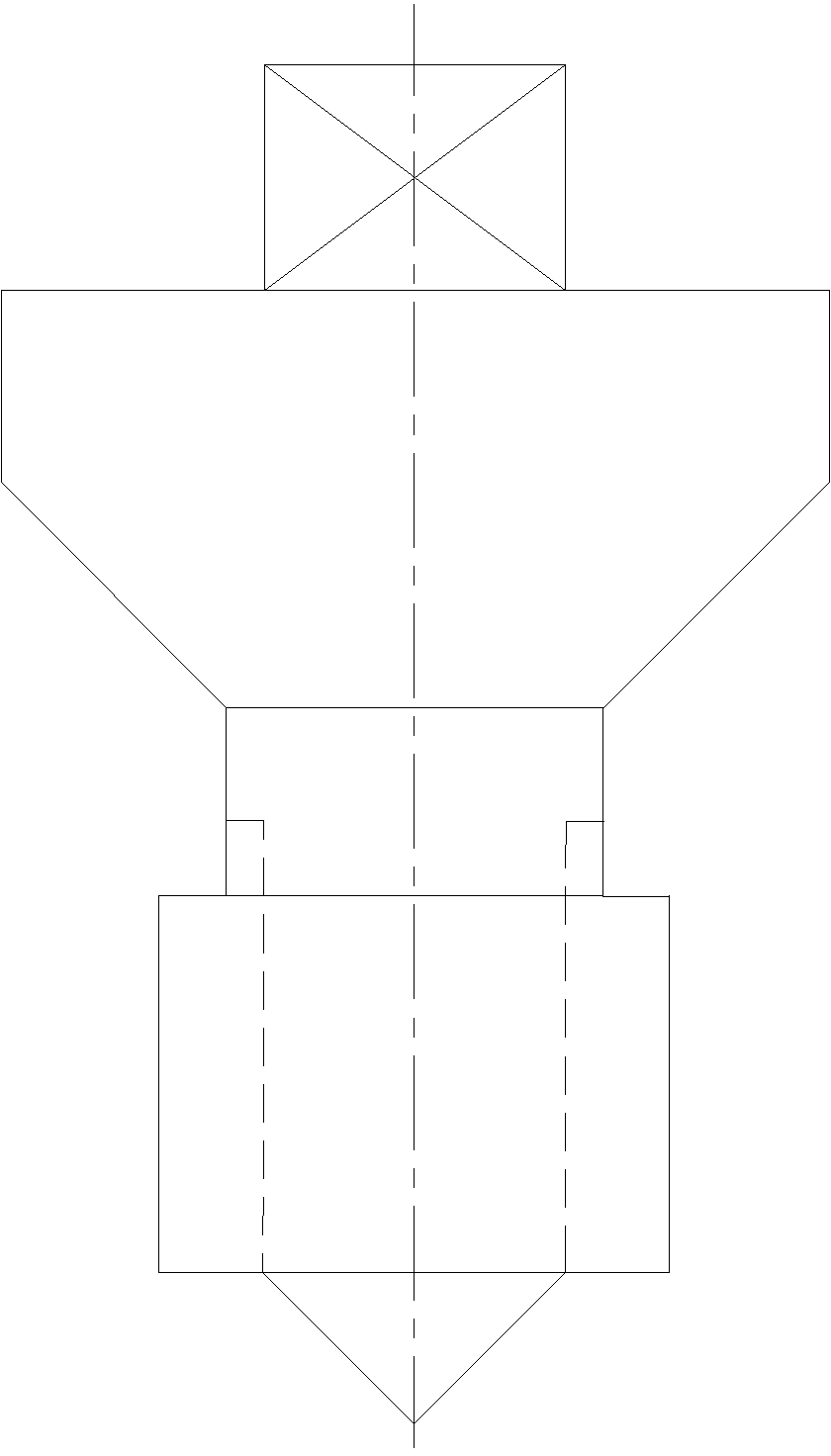

[0016] preferred embodiment, such as Figure 1 to Figure 5 As shown, the steel pipe inner wall descaling device provided by the present invention includes a tee pipe 1 and a high-pressure pipe 2 , and the end of the high-pressure pipe 2 is connected with a flow equalizer 4 through a transition joint 3 . The three-way pipe 1 includes two coaxial ports and one oblique port. The high-pressure pipe 2 passes through the two coaxial ports of the three-way pipe 1. The two ports are externally connected to the high-pressure pipe 2 and the steel pipe to be descaled. 11 of the flange 5. The inner wall of the inlet end of the tee pipe 1 has a sealing assembly 6 that fits with the high-pressure pipe 2 in a gap, and the sealing assembly 6 is pressed against the matching flange 8 to play a sealing role; the steel pipe 11 to be descaled is connected to the fastening flange 10 through the set screw Connection, the fastening flange 10 is connected with the flange 5 at the outlet end of the te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com