A method and device for continuous treatment of flue gas

A treatment method and flue gas technology, which are applied to combined devices, separation methods, chemical instruments and methods, etc., can solve the problems of increasing the dust content in the air, affecting people's normal breathing, etc., and achieve the effect of less solid matter content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

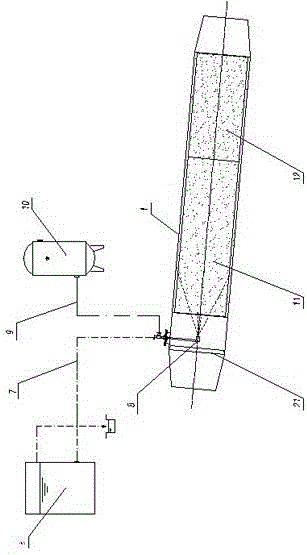

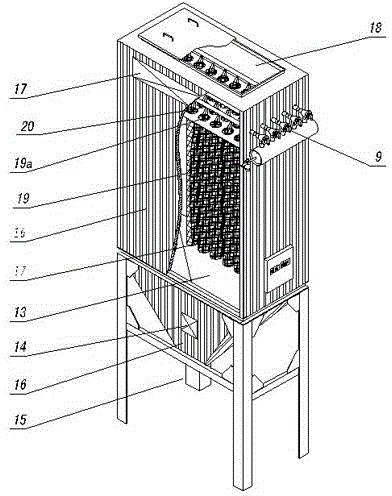

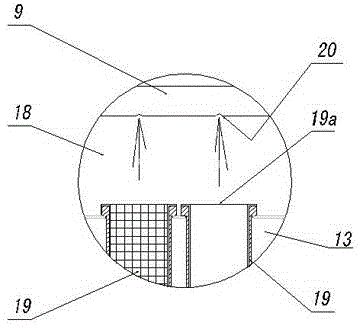

[0014] Now in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

[0015] The flue gas continuous treatment method of the present invention is realized in this way, including the sulfide removal process and the smoke and dust removal process. The sulfide removal process is to introduce the flue gas in a high temperature and high turbulence state into the air guide pipe to reduce the turbulence of the flue gas , at the same time, spray lye in the form of scattered droplets with a diameter of 50-100 μm through the nozzle arranged in the middle of the air duct in the same direction as the flow of the flue gas. The sulfide reaction in the reaction produces Na 2 SO 3 、Na 2 SO 4 solution drops, Na 2 SO 3 、Na 2 SO 4 Solution drops and residual lye mist are dried into Na at high temperature in the flue gas 2 SO 3 、Na 2 SO 4 Dust, NaOH dust, when the liquid droplets are completely evaporated, the sulfur oxides can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com