Carbon dioxide aeration electrochemical descaling device and method

A carbon dioxide and electrochemical technology, applied in the field of water treatment, can solve the problems of decreased removal rate of hardness ions, further improvement of electrochemical descaling efficiency, and unconsidered problems, so as to delay deposition, promote ion migration and chemical reaction, and increase usage The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment, and its content is explanation of the present invention rather than limitation:

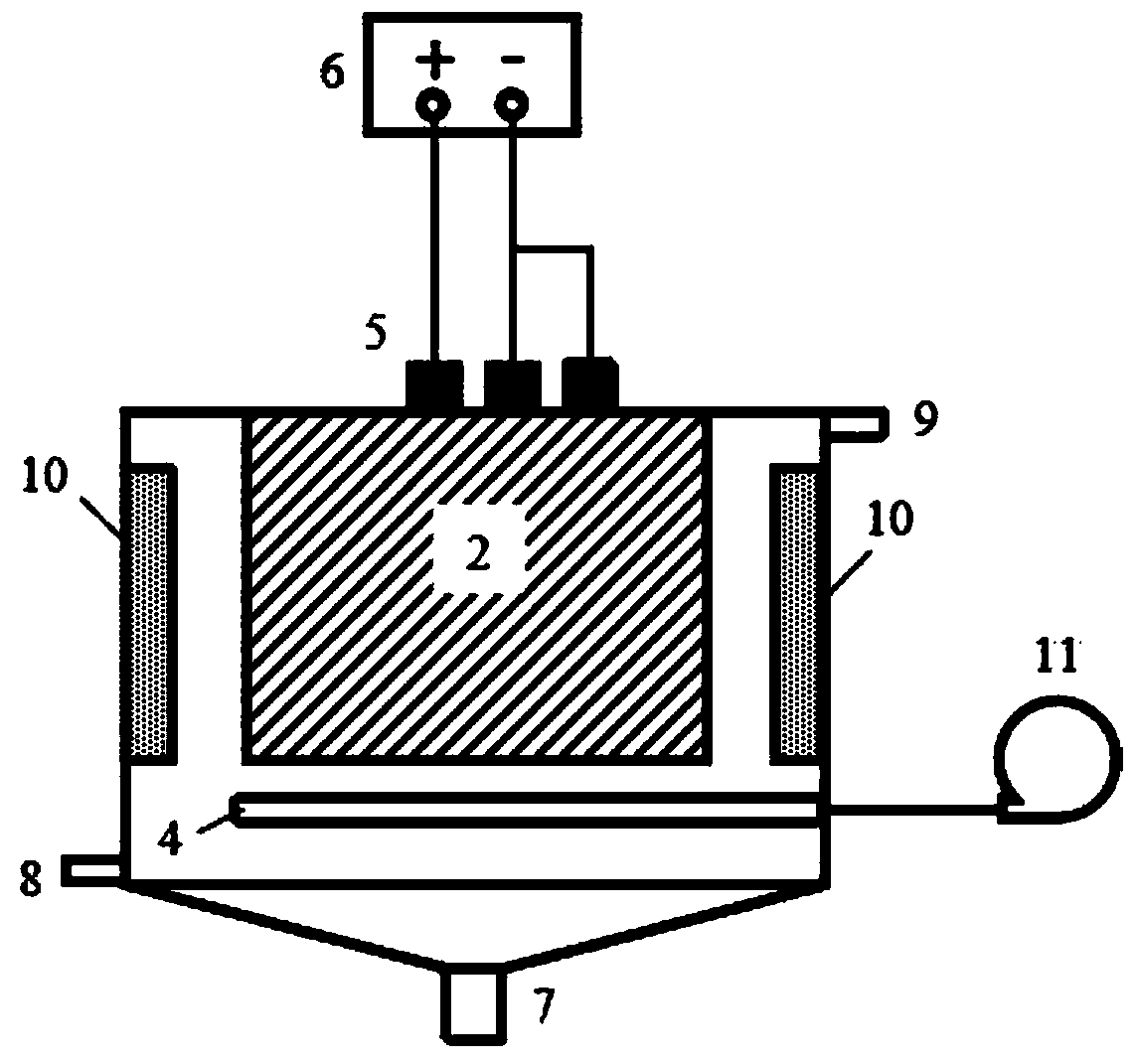

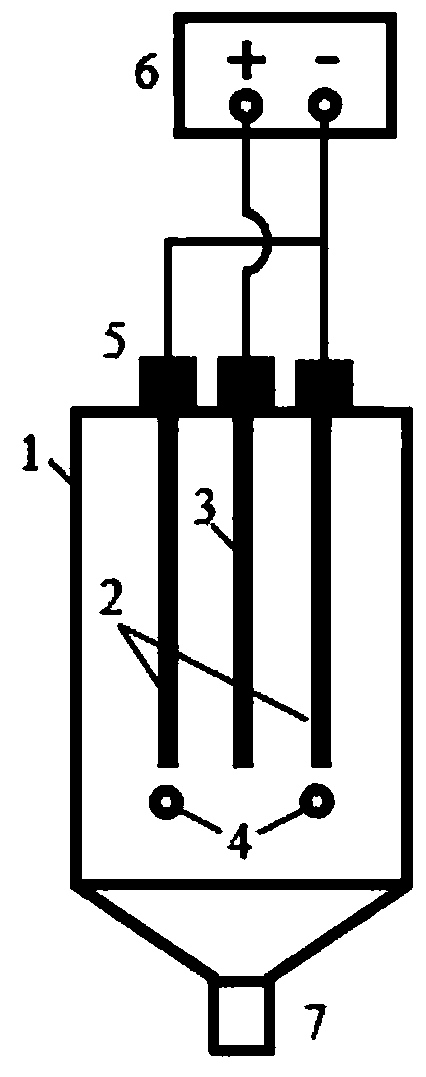

[0028] figure 1 , figure 2 The carbon dioxide aeration electrochemical descaling device of the present invention includes a reactor cylinder 1, several cathode plates 2, several anode plates 3 and aeration tubes 4; the inside of the reactor cylinder 1 is provided with an ultrasonic cleaner 10, preferably , the ultrasonic cleaner 10 is arranged at both ends of the reactor cylinder 1, and the sounding plane of the ultrasonic cleaner 10 is perpendicular to the polar plate plane of the cathode plate 2 and the anode plate 3. The lower plane of the reactor cylinder 1 is a funnel-shaped structure. When the reactor cylinder 1 is a cuboid, the lower parts of the four sides are respectively connected with four slopes, and the four slopes form a funnel shape; when the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com