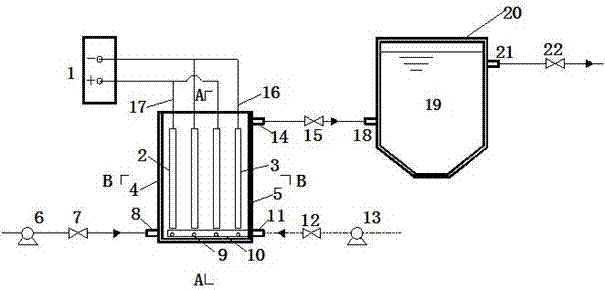

Electrochemical water softening method and system using air scouring descaling

An air scouring, electrochemical technology, applied in chemical instruments and methods, water softening, water/sewage multi-stage treatment, etc. The effect of decreasing and increasing the effective area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

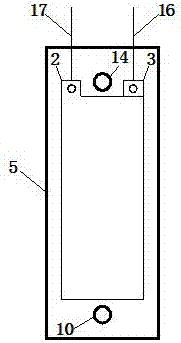

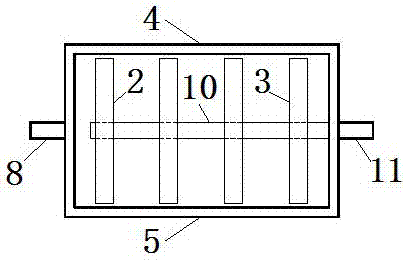

Method used

Image

Examples

Embodiment

[0039] Industrial circulating water with a hardness of about 350mg / L is treated by the system of the present invention. The system uses a DSA plate anode and a mirror stainless steel plate cathode. The size of the electrodes is 21x7x2 cm, the net distance between the two electrodes is 5mm, and the reactor volume is 100mL. The operating conditions are as follows: current density 100A / m 2 ; Average voltage 7V; softening stage treatment water flow rate 10L / h; softening stage treatment lasted 12h; descaling stage water flow rate 10L / h; descaling stage air velocity 45L / min; descaling stage time 5min. The running results are as follows: the average removal rate of total hardness ions in the treated effluent is 13.7%, and the deposition rate is 12g / h / m 2 , energy consumption 20 kWh / kg CaCO 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com