High-efficiency concentrated laundry detergent

A laundry liquid, high-efficiency technology, applied in the directions of detergent compounding agent, detergent composition, soap detergent composition, etc., to achieve the effects of good softness, prevention of re-precipitation, and inhibition of bacterial growth of clothes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

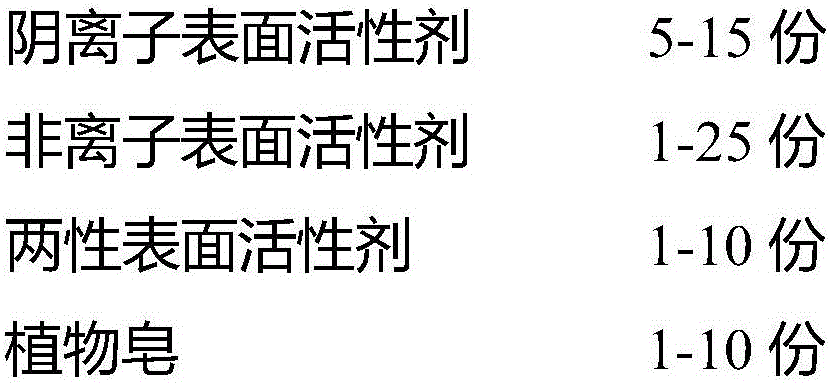

[0022] A kind of concentrated laundry liquid, its component and mass parts thereof are:

[0023]

[0024] According to above-mentioned formula preparation method is as follows:

[0025] 1. Add 44.3 parts of measured deionized water in turn, heat up to 50°C-60°C, add 1g of potassium hydroxide and stir until completely dissolved, add 4g of coconut oil and stir at 50°C-60°C to saponify with potassium hydroxide React until the saponification is complete and the solution is clear.

[0026] 2. Add MES and APG at 50°C and stir to dissolve, add AES and stir slowly until AES is completely dissolved.

[0027] 3. Stop heating, add MEE and stir evenly, add BS-12 and stir evenly, check the pH of the base solution with pH test paper, add sodium polyacrylate, and adjust the pH value of the solution with a small amount of citric acid or caustic soda.

[0028] 4. When the temperature is below 30°C, add dichlorophenoxychlorophene, multifunctional enzyme and essence.

Embodiment 2

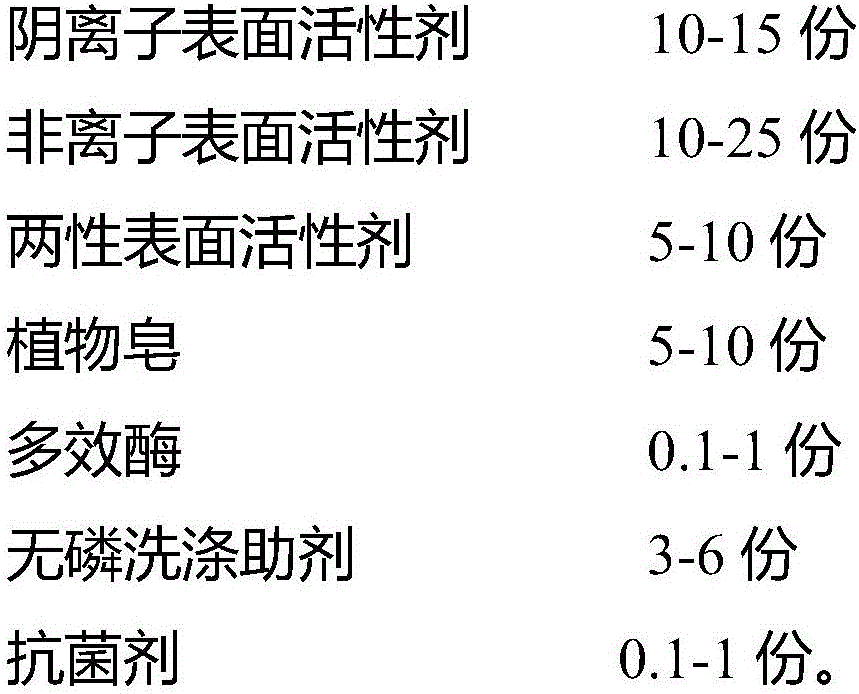

[0030] According to the same preparation method as in Example 1, the concentrated laundry detergent with the following main active components and mass parts is prepared:

[0031]

[0032]

[0033] Comparison between the present invention and the washing effect of commercially available common laundry detergent

[0034] Select Example 1 and compare the decontamination performance of commercially available common laundry detergent, put the standard stained cloth (stains are carbon black, protein, sebum) measured in advance into the decontamination machine. Add two kinds of laundry detergent respectively, turn on the decontamination machine to rinse and wash the soiled cloth, measure the whiteness of the soiled cloth after drying, the difference between the whiteness before and after reflects the decontamination ability, the larger the difference, the better the detergency it is good. The test results are shown in Table 1.

[0035] Table 1 Comparison of whiteness differen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com