An industrial wastewater treatment device

A technology for treating device and industrial wastewater, which is applied in the process of wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. The effect of ball crossing and increasing burr density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

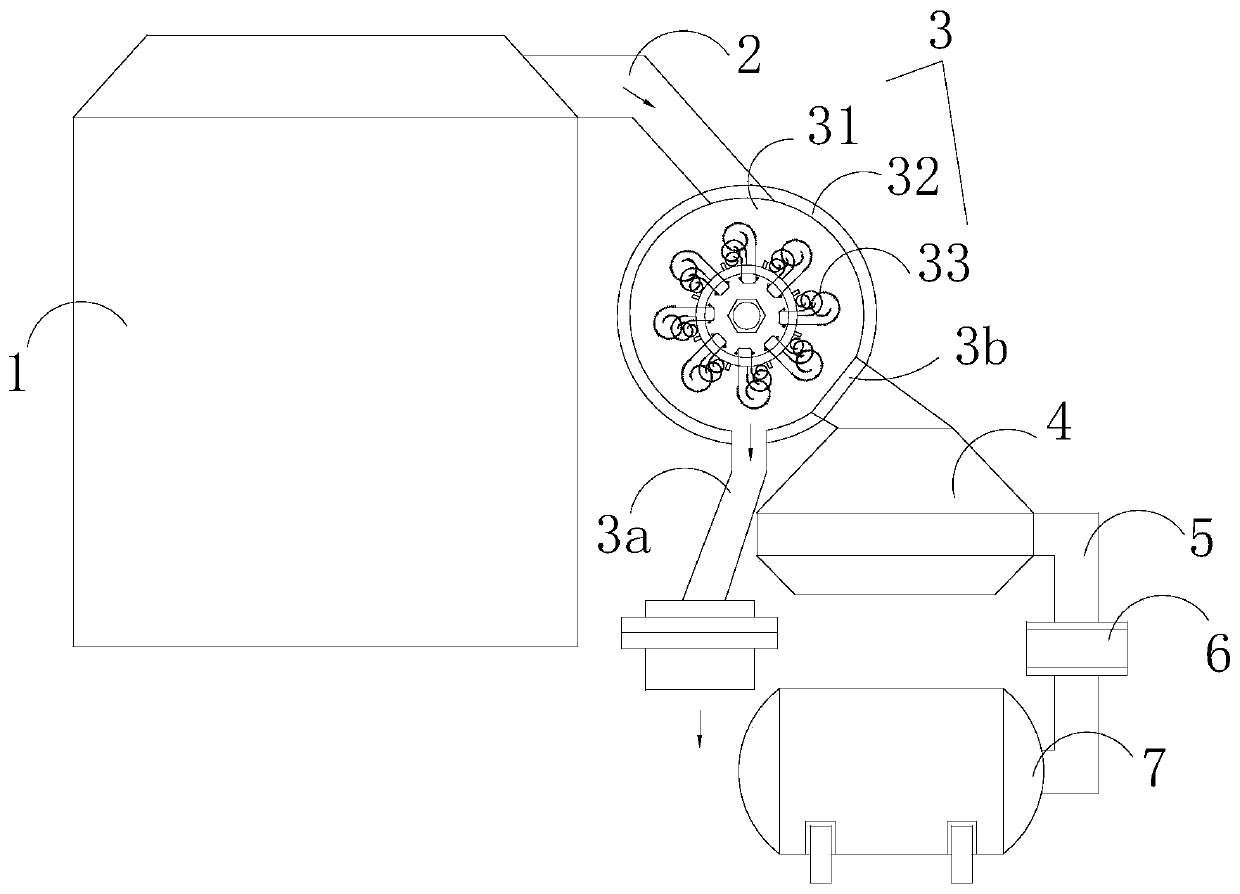

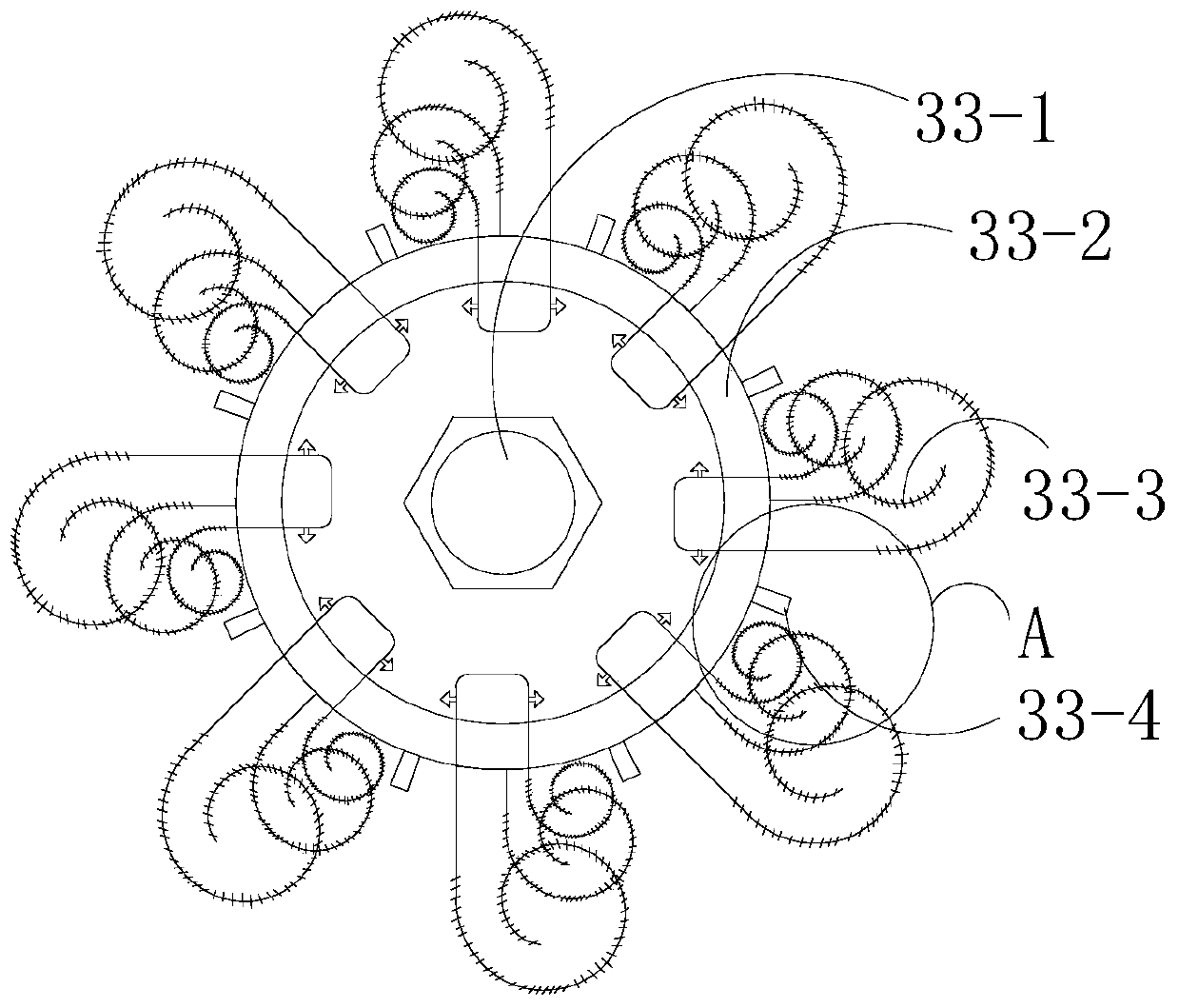

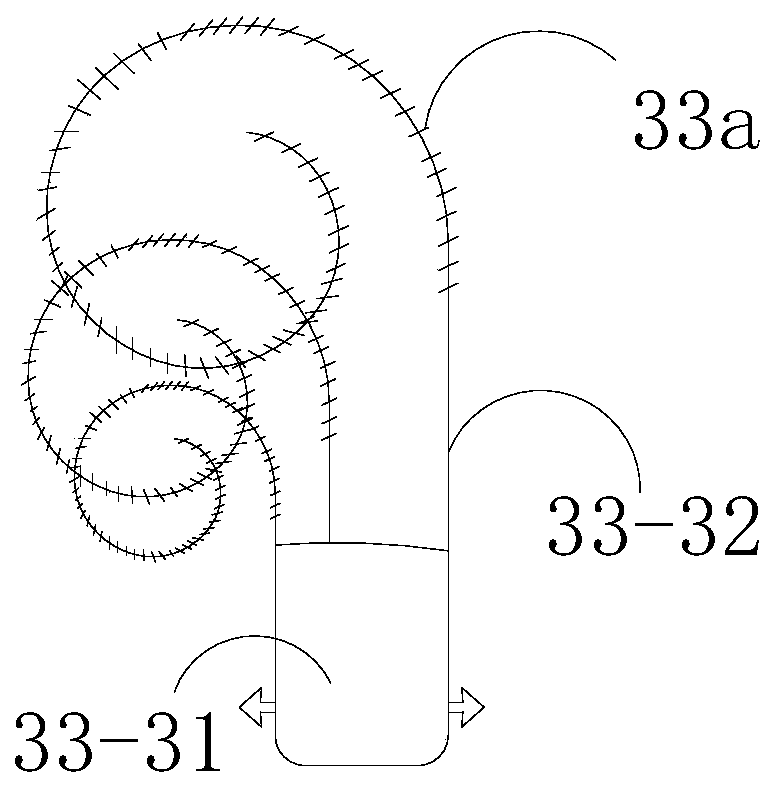

[0028] see Figure 1-Figure 5 , the present invention provides a kind of industrial waste water treatment device, 1. its structure comprises waste water pool 1, discharge pipe 2, soft thorn collection mechanism 3, settling tank 4, ventilation pipe 5, valve 6, negative pressure pump 7, described waste water pool 1. A discharge pipe 2 is provided on the side of the top end. One end of the discharge pipe 2 communicates with the waste water pool 1. The other end of the discharge pipe 2 communicates with the soft thorn collection mechanism 3 located obliquely below. The soft thorn collection mechanism 3 is connected to the discharge pipe 2 is provided with a settling box 4 on the opposite side. The settling box 4 is mechanically connected with the soft thorn collection mechanism 3. The installation position of the settling box 4 is lower than the soft thorn collection mechanism 3. The settling box 4 passes through the ventilation pipe 5 is mechanically connected with the negative p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com