Flat plate electrospray emission device with micro channels

A launch device, electrospray technology, applied in the direction of electrostatic spray device, spray device, spray electric energy device, etc., can solve the problems that cannot be disassembled and repaired, the silicon-based material is easily damaged, and it is not easy to expand on a large scale, so as to achieve improvement and scalability performance, stable operation, and avoidance of diffusion and coalescence problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation examples. However, it should be noted that implementation of the present invention is not limited to the following embodiments.

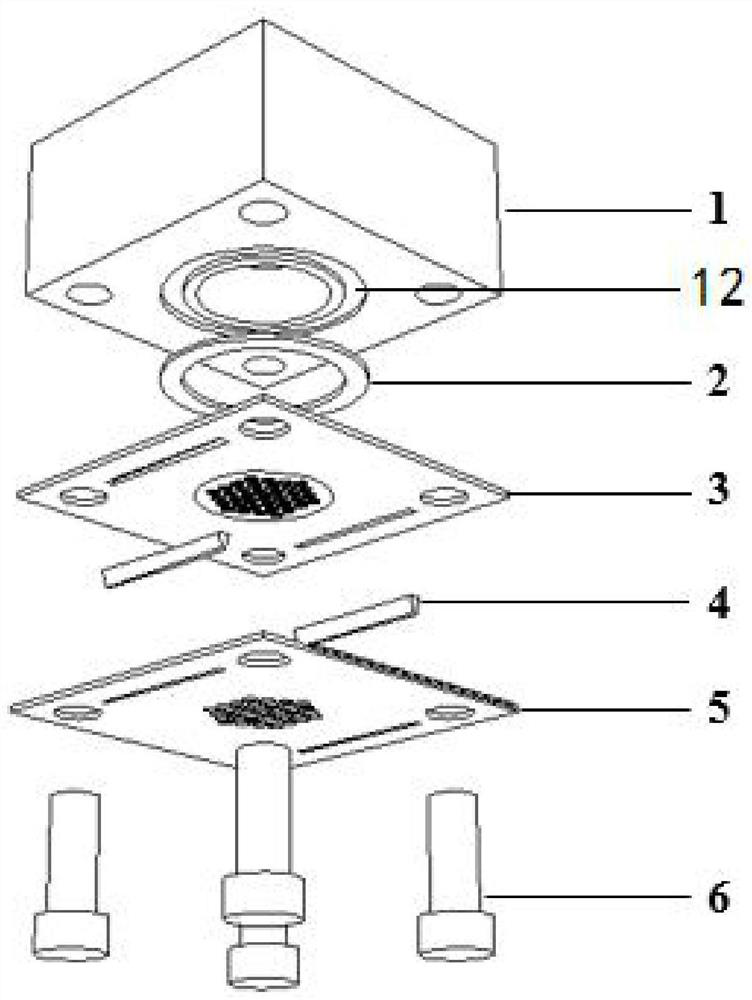

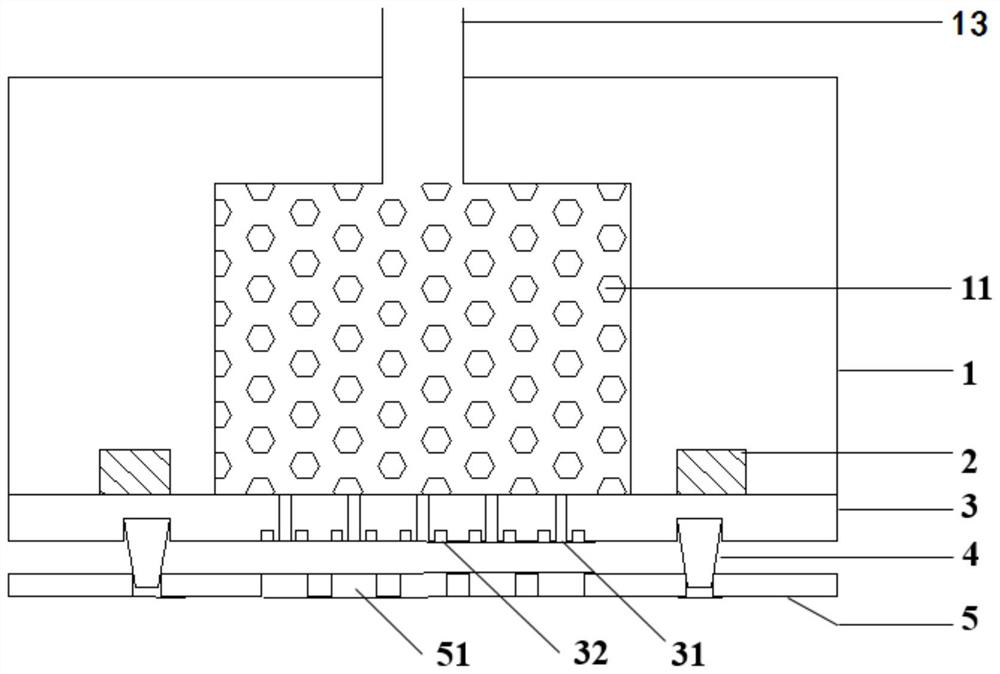

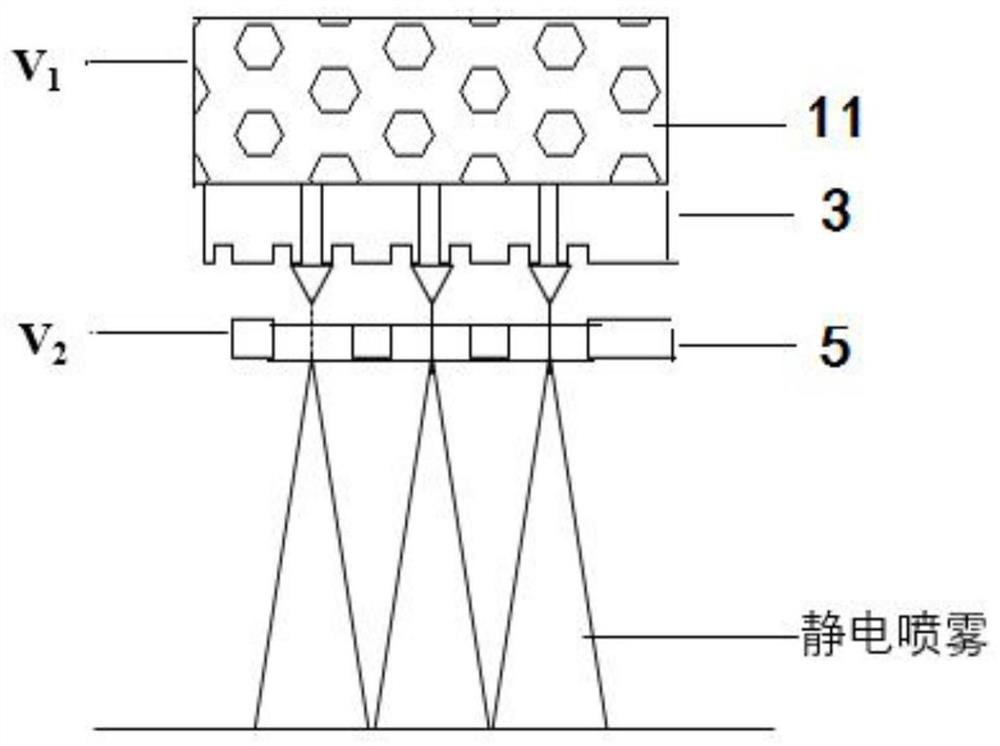

[0019] see Figure 1 to Figure 3 , a flat electrospray emission device with micro channels, comprising a liquid storage tank 1, a flat plate emitter 3 and an extraction electrode 5 arranged sequentially from top to bottom; the liquid storage tank 1 is provided with a porous dielectric material 11 and the working substance required for electrospray; a liquid outlet hole 12 is provided at the center of the lower end plate of the liquid storage tank 1, and an inlet connecting pipe 13 is arranged on the liquid storage tank 1, and the flat emitter 3 and the outlet The corresponding position of the liquid hole is provided with some emission holes 31, and the extraction electrode 5 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com