Supergravity heterogeneous catalytic reactor device and application thereof

A heterogeneous catalysis and reactor technology, applied in chemical instruments and methods, chemical/physical processes, sustainable biological treatment, etc., can solve the problem of poor gas-liquid mass transfer process and unclear flow state of microbubble catalyst bed To achieve the effect of increasing the reaction rate, improving the intrinsic safety, and avoiding the problem of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] The ultra-gravity heterogeneous catalytic reaction device of the present invention is applied to the gas-liquid-solid three-phase catalytic hydrogenation reaction as a reactor, comprising the following steps:

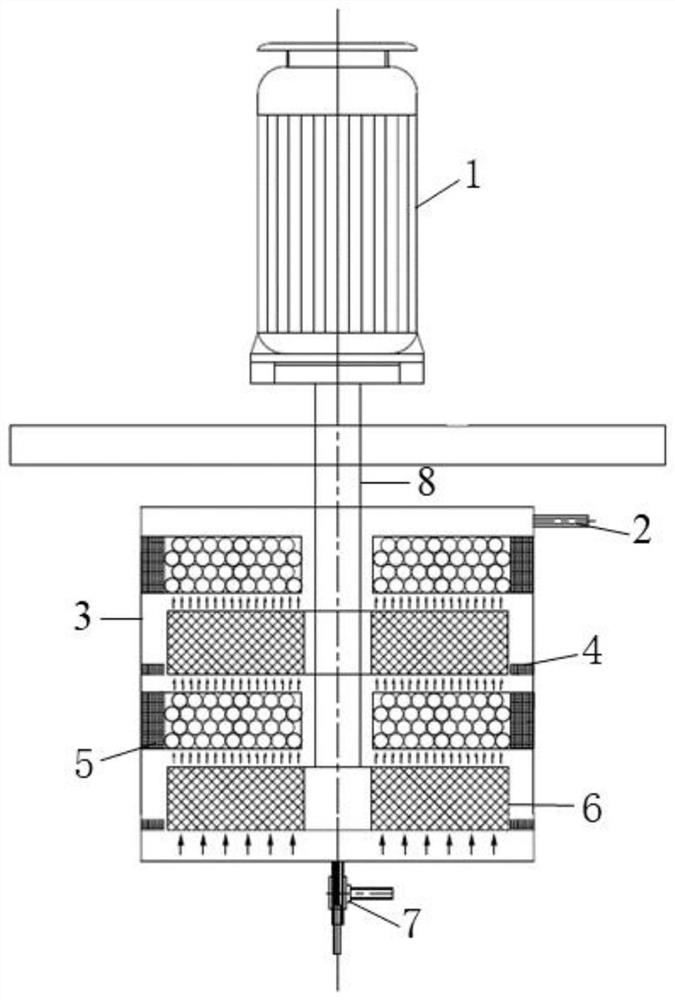

[0075] refer to Figure 4 shown, using figure 1 The device shown is applied to catalytic hydrogenation reaction, and the reaction system device includes hypergravity heterogeneous catalytic reaction device-9, nitrogen cylinder-10, hydrogen cylinder-11, gas mass flow meter-12, plunger pump-13, condensing tank- 14. Back pressure valve-15, gas-liquid separation tank-16, raw material tank-17, ball valve-18, wherein the supergravity heterogeneous catalytic reaction device and the raw material tank are equipped with electric heating jackets, and the reaction process includes the following steps:

[0076] 1) Connect the gas cylinder and the raw material tank respectively at the gas-liquid inlet of the supergravity heterogeneous catalytic reaction device, connect the c...

Embodiment 2

[0082] The ultra-gravity heterogeneous catalytic reaction device of the present invention is applied to the gas-liquid-solid three-phase catalytic hydrogenation reaction as a reactor, comprising the following steps:

[0083] refer to Figure 4 shown, using figure 1 The device shown is applied to catalytic oxidation reaction, including supergravity heterogeneous catalytic reaction device-9, nitrogen cylinder-10, oxygen cylinder-11, gas mass flow meter-12, plunger pump-13, condensation tank-14, back pressure Valve-15, gas-liquid separation tank-16, raw material tank-17, ball valve-18 wherein the supergravity microbubble heterogeneous catalytic reaction device and the raw material tank are equipped with electric heating jackets, and the reaction process includes the following steps:

[0084] 1) Connect the gas cylinder and the raw material tank respectively at the gas-liquid inlet of the supergravity heterogeneous catalytic reaction device, connect the condensation tank and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com