Graphene-based lithium-ion battery cathode and preparation method thereof

A lithium-ion battery and graphene technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor acceleration performance of electric vehicles, unsatisfactory battery energy density, and mileage requirements of electric vehicles, etc. Effects of ion transmission rate, improved power performance, and high binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

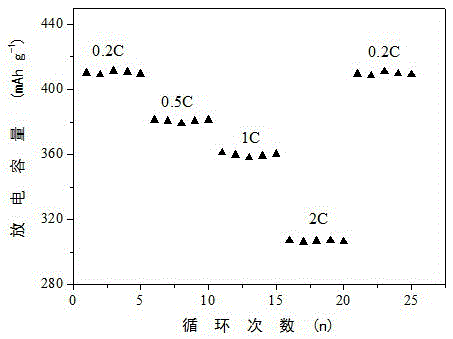

Embodiment 1

[0032] Coating the negative electrode slurry of the lithium ion battery on the copper foil to prepare the negative electrode of the lithium ion battery has a thickness of 200 microns. The weight ratio formula of each raw material in the slurry is: 35 parts by weight of graphite, 25 parts by weight of graphene, 2.5 parts by weight of binder, 2 parts by weight of thickener, and 70.0 parts by weight of dispersion medium. The particle size of the graphite is 500 mesh; the graphene is reduced graphene oxide with a particle size of 300 mesh. The binder is polystyrene-polyisoprene-polystyrene block copolymer latex, the molecular weight of the block copolymer is 15K-150K-15K, and the solid content of the latex is 35%. The thickener is sodium carboxymethyl cellulose; the dispersion medium is deionized water.

[0033] The lithium-ion battery negative electrode slurry is prepared through the following processing techniques: Add all thickeners, all conductive agents, all graphite and a...

Embodiment 2

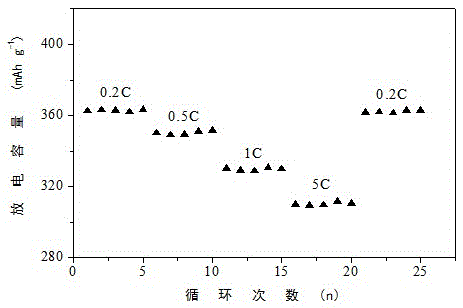

[0036] The lithium ion battery negative electrode slurry was coated on copper foil to prepare a lithium ion battery negative electrode with a thickness of 50 microns. The weight ratio formula of each raw material in the slurry is: 50 parts by weight of graphite, 15 parts by weight of graphene, 0.5 part by weight of binder, 0.25 part by weight of thickener, and 90.0 parts by weight of dispersion medium. The particle diameter of the graphite is 300 meshes; the graphene is reduced graphene oxide, and the particle diameter is 200 meshes. The binder is polystyrene-polyisoprene-polystyrene block copolymer latex, the molecular weight of the block copolymer is 50K-100K-50K, and the solid content of the latex is 15%. The thickener is sodium carboxymethyl cellulose; the dispersion medium is deionized water.

[0037] The lithium ion battery negative electrode slurry is prepared by the following processing technology: In the ball mill, add all the thickeners, all the conductive agents,...

Embodiment 3

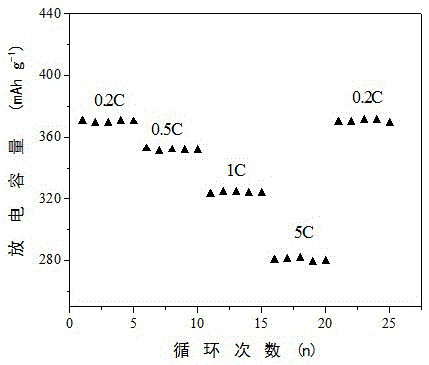

[0040] The lithium ion battery negative electrode slurry was coated on copper foil to prepare a lithium ion battery negative electrode with a thickness of 150 microns. The weight ratio of each raw material in the slurry is as follows: 45 parts by weight of graphite, 10 parts by weight of graphene, 1.5 parts by weight of binder, 1 part by weight of thickener, and 80 parts by weight of dispersion medium. The particle diameter of the graphite is 300 meshes; the graphene is reduced graphene oxide, and the particle diameter is 200 meshes. The binder is polystyrene-polyisoprene-polystyrene block copolymer latex, the molecular weight of the block copolymer is 15K-40K-15K, and the solid content of the latex is 35%. The thickener is sodium carboxymethyl cellulose; the dispersion medium is deionized water.

[0041] The lithium ion battery negative electrode slurry is prepared by the following processing technology: In the ball mill, add all the thickeners, all the conductive agents, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com