Process and apparatus for producing metal nanoparticles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example — 1

EXAMPLE—1

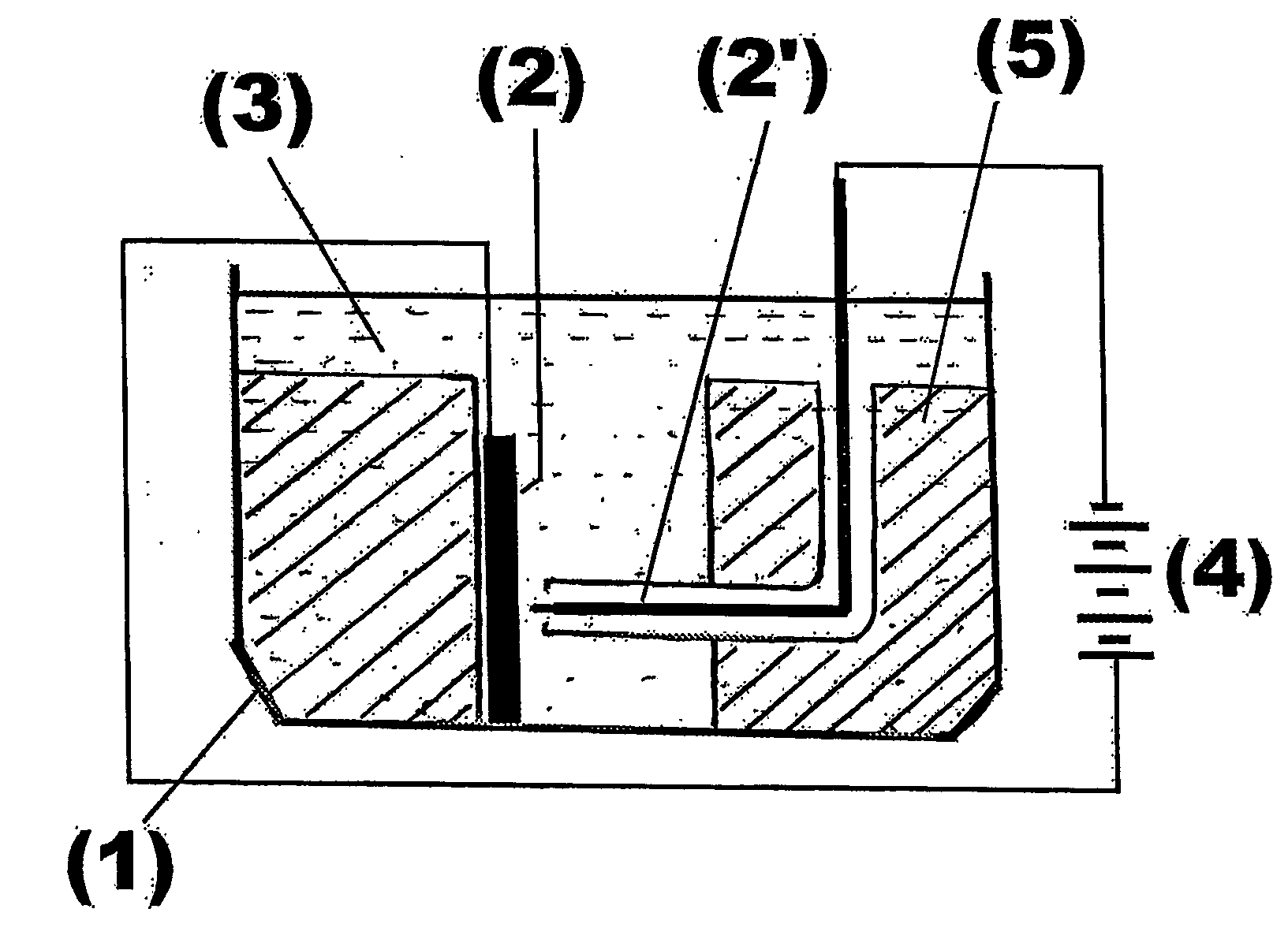

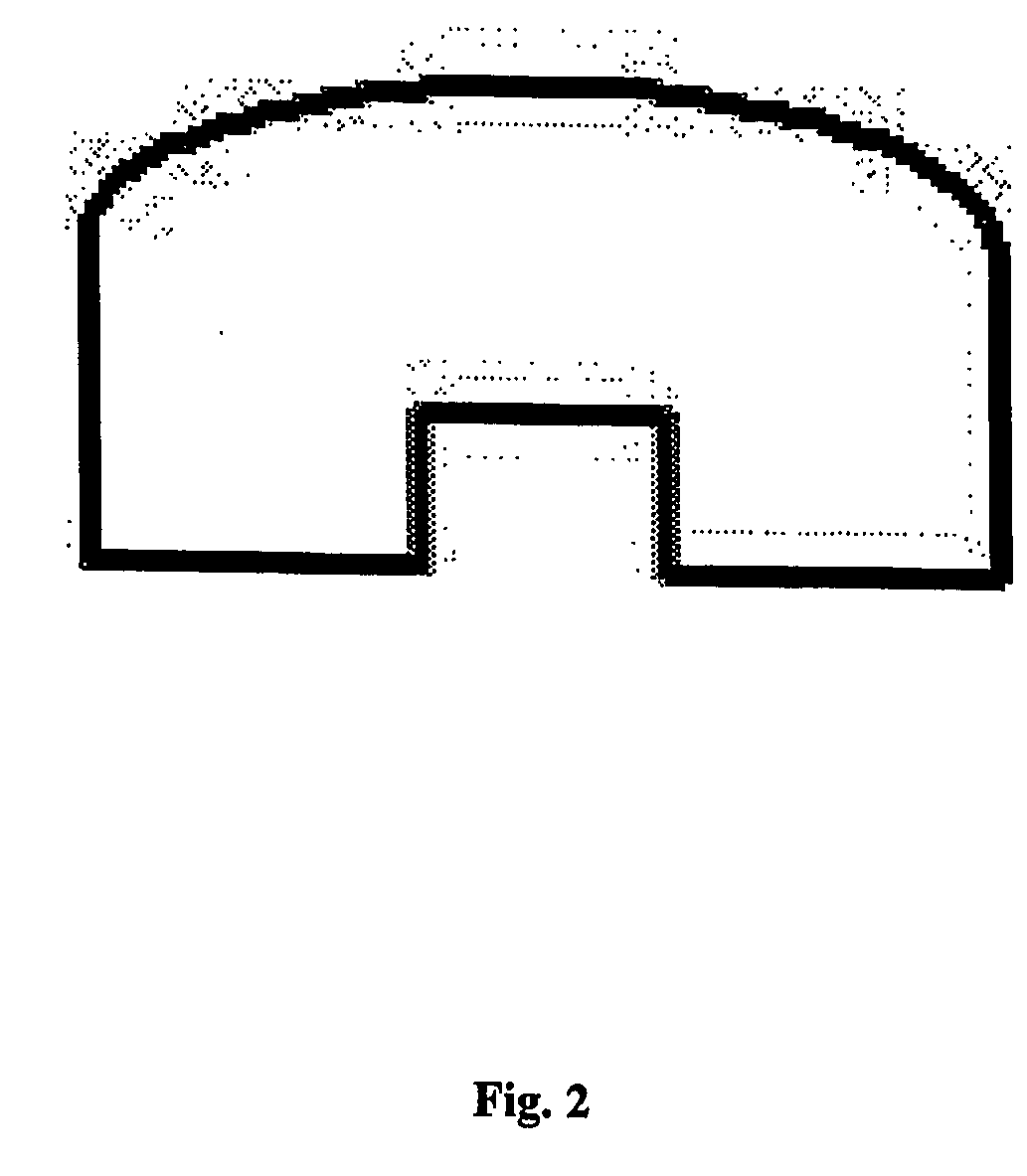

[0073] A reaction vessel for preparation of nanomaterials employing the exploding wire technique was constructed out of glass with an arrangement for mounting a copper metal plate (electrode 1) perpendicular to the base of the reactor. A wire guide arrangement is placed so that a copper wire (electrode 2), while passing through the guide, approaches the plate along its normal. The metal plate and the wire form the two electrodes which is connected to a battery bank allowing for supply of voltages starting at 12 V and going up to 48V in incremental steps of 12 V. The reactor vessel is filled up with a suitable dense medium so as to completely immerse electrode 2 and 66% of electrode 1.

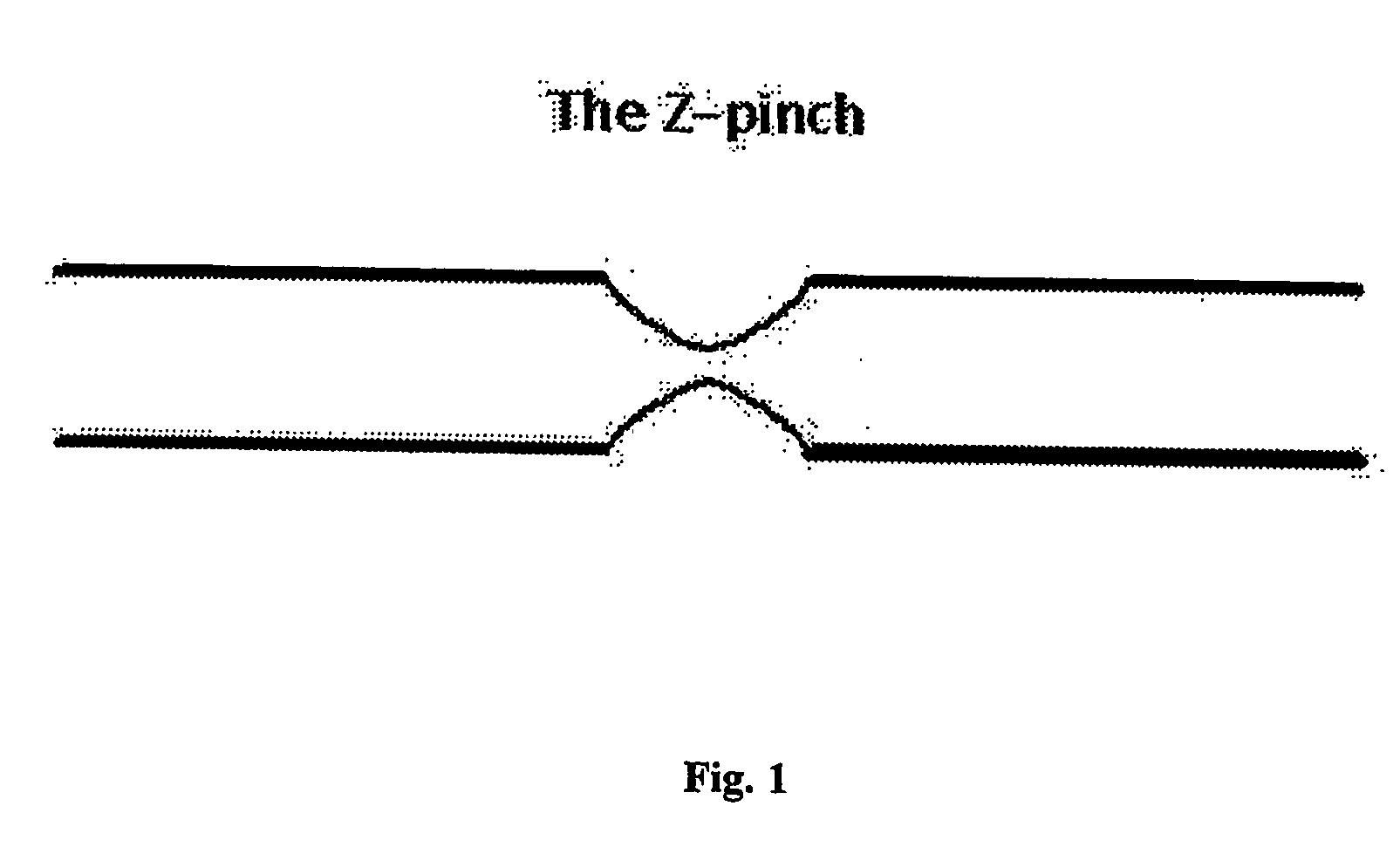

[0074] The batteries were connected so as to have electrode 2 connected to the positive terminal of the battery and electrode 2′ to the negative terminal. Electrode 2′ is brought into contact with electrode 2 to achieve an explosion, following which the current naturally falls to zero. This si...

example — 2

EXAMPLE—2

[0076] A reaction vessel for preparation of nanomaterials employing the exploding wire technique was constructed out of glass with an arrangement for mounting a silver metal plate (electrode 2) perpendicular to the base of the reactor. A wire guide arrangement is placed so that a silver wire (electrode 2′), while passing through the guide, approaches the plate along its normal. The metal plate and the wire form the two electrodes which is connected to a battery bank allowing for supply of voltages starting at 12 V and going up to 48 V in incremental steps of 12 V. The reactor vessel is filled up with a suitable dense medium so as to completely immerse electrode 2 and 66% of electrode 1.

[0077] The batteries were connected so as to have electrode 1 connected to the positive terminal of the battery and electrode 2 to the negative terminal. Electrode 2′ is brought into contact with electrode 2 to achieve an explosion, following which the current naturally falls to zero. This s...

example — 3

EXAMPLE—3

[0080] A reaction vessel for preparation of nanomaterials employing the exploding wire technique was constructed out of glass with an arrangement for mounting an iron metal plate (electrode 2) perpendicular to the base of the reactor. A wire guide arrangement is placed so that an iron wire (electrode 2′), while passing through the guide, approaches the plate along its normal. The metal plate and the wire form the two electrodes which is connected to a battery bank allowing for supply of voltages starting at 12 V and going upto 48 V in incremental steps of 12 V. The reactor vessel is filled up with a suitable dense medium so as to completely immerse electrode 2 and 66% of electrode 1.

[0081] The batteries were connected so as to have electrode 1 connected to the positive terminal of the battery and electrode 2 to the negative terminal. Electrode 2 is brought into contact with electrode 1 to achieve an explosion, following which the current naturally falls to zero. This signa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Electric potential / voltage | aaaaa | aaaaa |

| Electric potential / voltage | aaaaa | aaaaa |

| Electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com