Environment-friendly efficient alcohol-free vegetable oil fuel and preparation method thereof

A vegetable oil, high-efficiency technology, applied in fuel, fuel additive, liquid carbon-containing fuel, etc., can solve the problems of air pollution, difficult storage, high energy density of diesel oil, etc., to reduce carbon monoxide emissions, ensure combustion performance, and improve corrosion resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] An environmentally friendly and efficient alcohol-free vegetable oil fuel, prepared from the following raw materials in parts by weight: 800 parts of palm oil, 100 parts of polysiloxane, 0.2 parts of methyl tert-butyl ether, 2 parts of isopropanol, ethylene glycol 5 parts, 0.5 parts of glycerol, 1 part of absolute ethanol, 1 part of magnesium powder, 0.1 part of ferrocene, and 5 parts of water.

[0028] A method for preparing an environmentally friendly and highly efficient alcohol-free vegetable oil fuel, comprising the following steps:

[0029] S1: Add methyl tert-butyl ether to absolute ethanol, stir evenly, and let stand for 0.5 hours; then add glycerol, stir evenly, let stand for 0.5 hours, then add ethylene glycol, stir evenly, let stand for 0.5 hours , to get a mixture;

[0030] S2: Add the mixing agent and polysiloxane into the vegetable oil together, and stir for 20 minutes at a stirring speed of 1000 r / min to obtain a mixed solution, which is set aside;

[0...

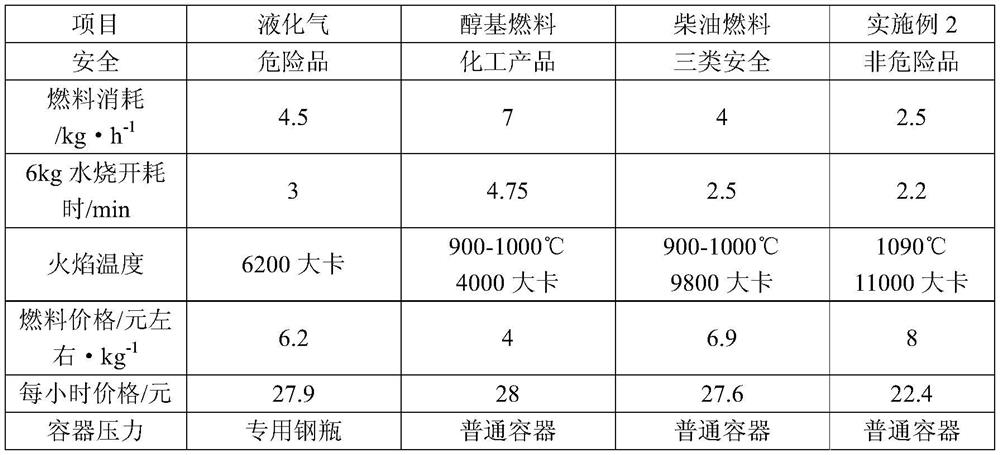

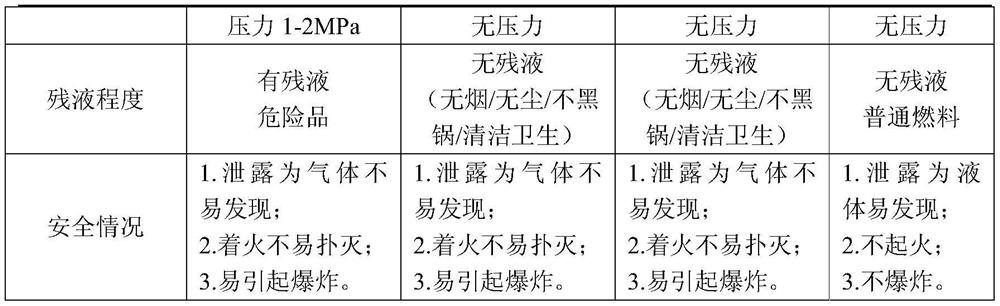

Embodiment 2

[0034] An environmentally friendly and highly efficient alcohol-free vegetable oil fuel, prepared from the following raw materials in parts by weight: 950 parts of tea seed oil, 60 parts of polysiloxane, 0.08 parts of methyl tert-butyl ether, 2.7 parts of isopropanol, ethylene glycol 5.7 parts of alcohol, 1 part of glycerin, 2 parts of absolute ethanol, 4 parts of magnesium powder, 0.05 parts of ferrocene, and 8 parts of water.

[0035] A method for preparing an environmentally friendly and highly efficient alcohol-free vegetable oil fuel, comprising the following steps:

[0036] S1: Add methyl tert-butyl ether into absolute ethanol, stir evenly, and let stand for 0.8 hours; then add glycerol, stir evenly, let stand for 0.8 hours, then add ethylene glycol, stir evenly, let stand for 0.8 hours , to get a mixture;

[0037] S2: Add the mixing agent and polysiloxane into the vegetable oil together, and stir for 15 minutes at a stirring speed of 1500 r / min to obtain a mixed soluti...

Embodiment 3

[0041] An environmentally friendly and efficient alcohol-free vegetable oil fuel, prepared from the following raw materials in parts by weight: 850 parts of palm oil, 80 parts of polysiloxane, 0.05 parts of methyl tert-butyl ether, 2.2 parts of isopropanol, ethylene glycol 6.4 parts, 0.6 parts of glycerol, 3 parts of absolute ethanol, 2 parts of magnesium powder, 0.5 parts of ferrocene, and 20 parts of water.

[0042] A method for preparing an environmentally friendly and highly efficient alcohol-free vegetable oil fuel, comprising the following steps:

[0043] S1: Add methyl tert-butyl ether to absolute ethanol, stir evenly, and let stand for 1.2 hours; then add glycerol, stir evenly, let stand for 1.1 hours, then add ethylene glycol, stir evenly, let stand for 1 hour , to get a mixture;

[0044] S2: Add the mixture and polysiloxane into the vegetable oil together, and stir for 18 minutes at a stirring speed of 1800r / min to obtain a mixture, which is set aside;

[0045]S3: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com