Device and method for preparing monodisperse ion exchange resin

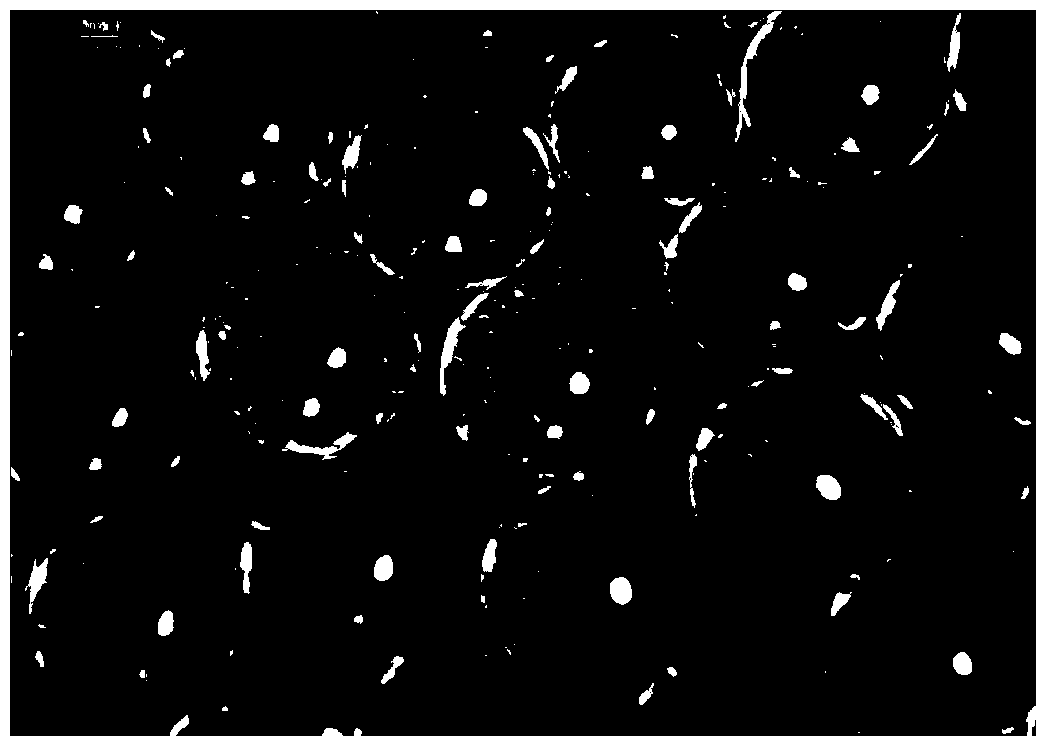

An ion exchange resin, monodisperse technology, applied in the field of preparation of exchange resins, can solve the problems of large diameter oil droplets, small interfacial tension, and the lack of monodispersity of beads, and achieve the effect of uniform particle size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

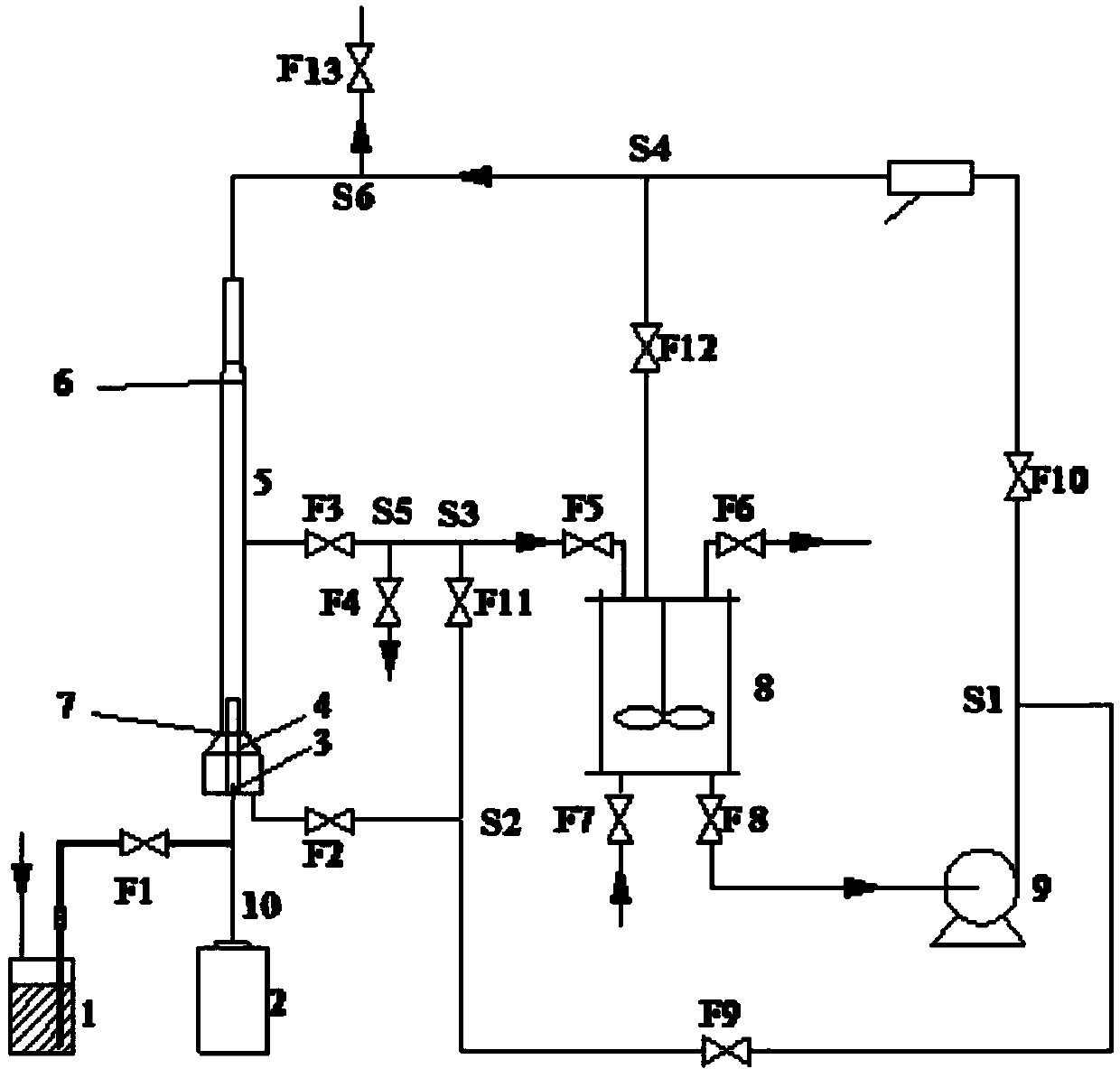

[0049] The method for preparing monodisperse ion exchange resin, comprises the steps:

[0050] (1) The equipment for preparing monodisperse ion exchange resin is used; wherein the upper porous plate is made of glass with a pore diameter of 0.3 mm to 0.8 mm. The material of the lower perforated plate is glass, and the aperture is 0.3mm~0.8mm;

[0051] (2) the mass percent of methyl acrylate 90g (polymerization monomer) that has removed polymerization inhibitor, removed polymerization inhibitor is 55% divinylbenzene 10g (crosslinking agent), benzoyl peroxide 2g (initiator agent) is mixed evenly and then added to the raw material tank 1, and the temperature of the raw material tank 1 is controlled to be 20-30° C. to obtain the reactant;

[0052] (3) dissolving polyvinyl alcohol (dispersant) in deionized water so that the mass concentration of polyvinyl alcohol is 3%, stirring and dissolving to obtain an aqueous phase;

[0053] (4) Water phase is charged in the pipeline between ...

Embodiment 2

[0073] The method for preparing monodisperse ion exchange resin, comprises the steps:

[0074] (1) Use equipment for preparing monodisperse ion exchange resin; wherein the material of the upper porous plate is stainless steel, and the pore diameter is 0.3 mm to 0.8 mm. The material of the lower perforated plate is stainless steel, and the hole diameter is 0.3mm~0.8mm;

[0075] (2) the mass percentage of the methyl acrylate 15g and methyl methacrylate 15g (polymerization monomer) that has removed polymerization inhibitor, removed polymerization inhibitor is 80g (cross-linking agent) of the mass percent of 55% dipropylene benzene, coupler 1.1 g of nitrogen bis(isobutyronitrile) (initiator) and 50 g of liquid paraffin (porogen) are uniformly mixed and then added to the raw material tank 1, and the temperature of the raw material tank 1 is controlled to be 20-30° C. to obtain the reactant;

[0076] (3) dissolving sodium lauryl sulfate (dispersant) in deionized water so that the m...

Embodiment 3

[0091] The method for preparing monodisperse ion exchange resin, comprises the steps:

[0092] (1) The equipment for preparing monodisperse ion exchange resin is used; wherein the material of the upper porous plate is ceramics, and the pore diameter is 0.3 mm to 0.8 mm. The material of the lower perforated plate is ceramics, and the aperture is 0.3mm-0.8mm;

[0093] (2) the styrene 30g (polymerization monomer) that has removed polymerization inhibitor, the mass percentage that has removed polymerization inhibitor is 55% divinylbenzene 10g (crosslinking agent), cumene hydroperoxide 0.5g ( Initiator), a mixture of toluene and hexane (the mass ratio of toluene to hexane is 3:7) 59.5g (porogen) is mixed evenly and then added to the raw material tank 1, and the temperature of the raw material tank 1 is controlled at 20-30°C to obtain the reaction thing;

[0094] (3) Dissolve the mixture of polyvinyl alcohol and sodium dodecylbenzene sulfonate (the mass ratio of polyvinyl alcohol ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com