High temperature-resistant high-mineralization degree foam scrubbing agent and its preparation method and use

A technology of foaming agent and surfactant, which is applied in the field of oil and gas exploitation, can solve the problems that are rarely reported, and achieve the effect of simple composition, good position adaptability, and enhanced compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This embodiment provides a high-temperature-resistant, high-salinity foam unloading agent and a preparation method thereof. The preparation method comprises the following steps:

[0031] 1) preparation of Gemini cationic surfactant

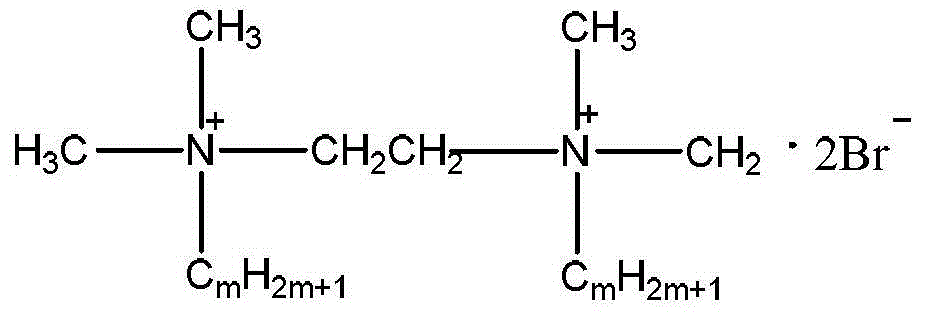

[0032] Separately mix 2g of dodecyldimethylammonium bromide, tetradecyldimethylammonium bromide, hexadecyldimethylammonium bromide, octadecyldimethylammonium bromide with 4mL of 1, 2-Dibromoethane (in excess to ensure that the reaction is fully completed) was dissolved in absolute ethanol (50 mL), and refluxed at about 80 ° C for 48 h. The reacted mixture was spin-dried at 37°C on a rotary evaporator to obtain Gemini cationic surfactants with m=12, 14, 16, and 18 respectively; the structure of the Gemini cationic surfactant is shown in formula I

[0033]

[0034] Wherein, in the present embodiment, the Gemini cationic surfactant is mixed according to the mass ratio of 1:1:3:1 by the Gemini cationic surfactant of above-mentioned m=12,14...

Embodiment 2

[0039] This embodiment provides a foaming agent with high temperature resistance and high salinity and its preparation method. The preparation method comprises the following steps:

[0040] 1) preparation of Gemini cationic surfactant

[0041] Separately mix 2g of dodecyldimethylammonium bromide, tetradecyldimethylammonium bromide, hexadecyldimethylammonium bromide, octadecyldimethylammonium bromide with 4mL of 1, 2-Dibromoethane (in excess to ensure that the reaction is fully completed) was dissolved in absolute ethanol (50 mL), and refluxed at about 80 ° C for 48 h. The reacted mixture was spin-dried at 37°C on a rotary evaporator to obtain Gemini cationic surfactants with m=12, 14, 16, and 18 respectively; the structure of the Gemini cationic surfactant is shown in formula I

[0042]

[0043] Wherein, in the present embodiment, the Gemini cationic surfactant is mixed according to the mass ratio of 1:1:3:1 by the Gemini cationic surfactant of above-mentioned m=12,14,16,...

Embodiment 3

[0048] This example is aimed at the initial foaming volume V of the foaming agent GWJ-1 provided in the above example 1 under different temperature and salinity conditions 0 , foam half-life t 1 / 2 And the liquid carrying capacity of 15 minutes when the air flow rate is 5L / min was tested, and the performance of a domestic commercially available foam discharge agent 1 and 2 was compared under the same test conditions.

[0049]The instrument used in the test process is a high temperature and high pressure foam evaluation instrument (this high temperature and high pressure foam evaluation instrument is the high temperature and high pressure foam evaluation instrument recorded in the utility model patent of patent number ZL201120400940.1, bulletin number CN202228059U); In order to analyze the water produced by the natural gas well on site, NaCl, CaCl were used. 2 , MgCl 2 , KCl, Na 2 SO 4 , NaHCO 3 Prepared.

[0050] The specific test method is as follows:

[0051] 1) Foamin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com