High-stability oil displacement foam system and preparation method thereof

A technology of foam system and high stability, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of foam stability decline, affecting the recovery rate of oil field foam flooding, etc., to prevent oil droplets from coalescing , Improve the performance of emulsification and washing oil, and the effect of high product conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

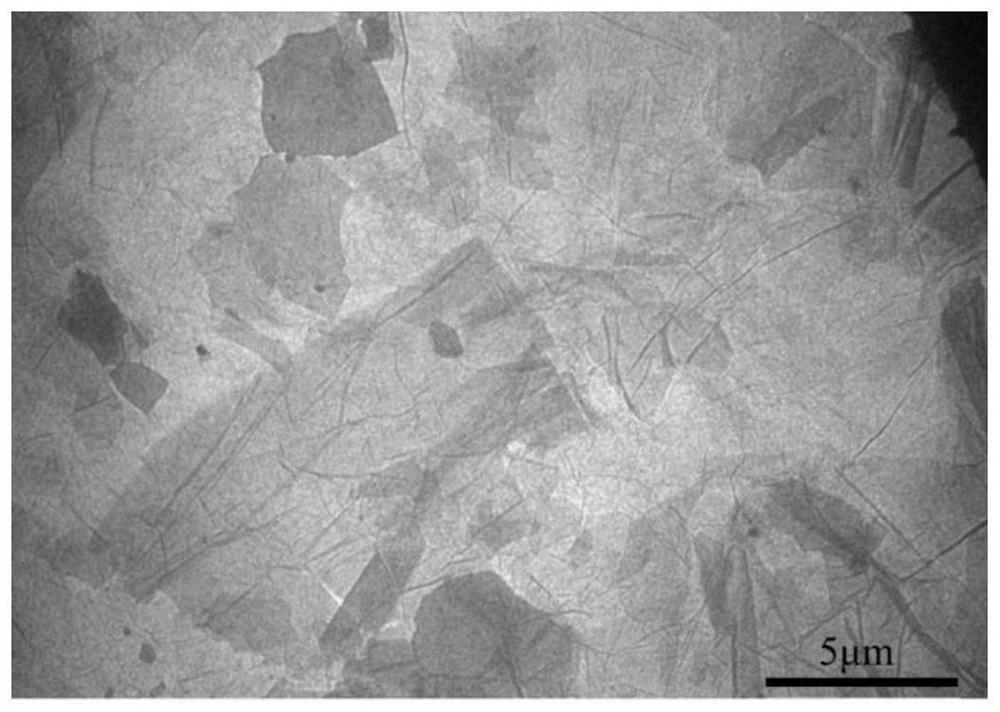

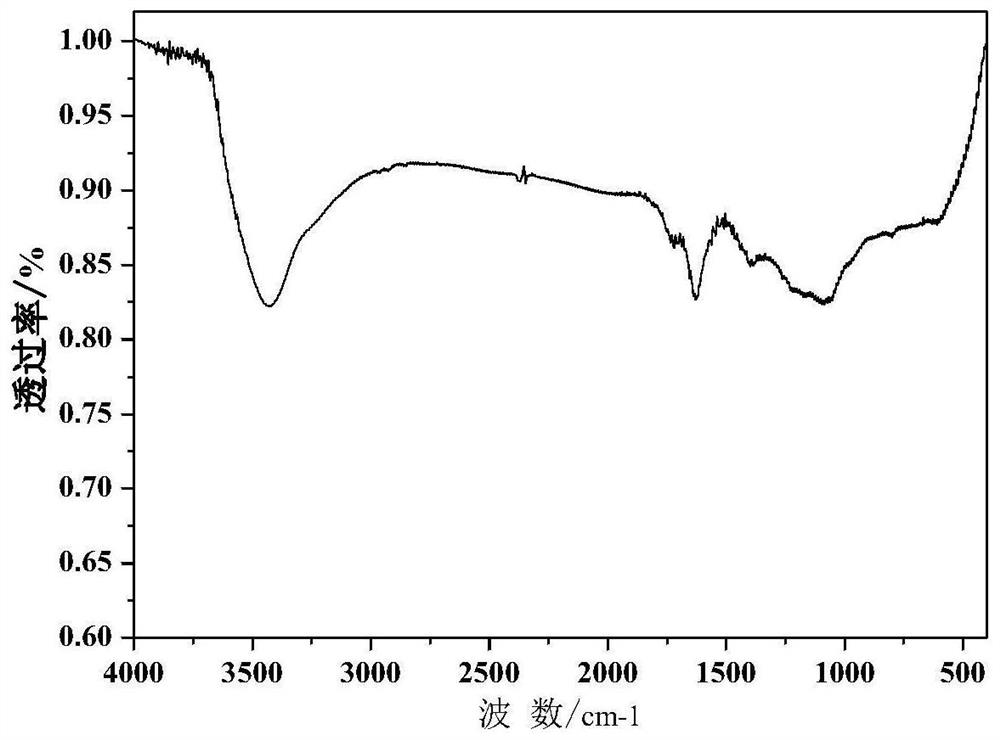

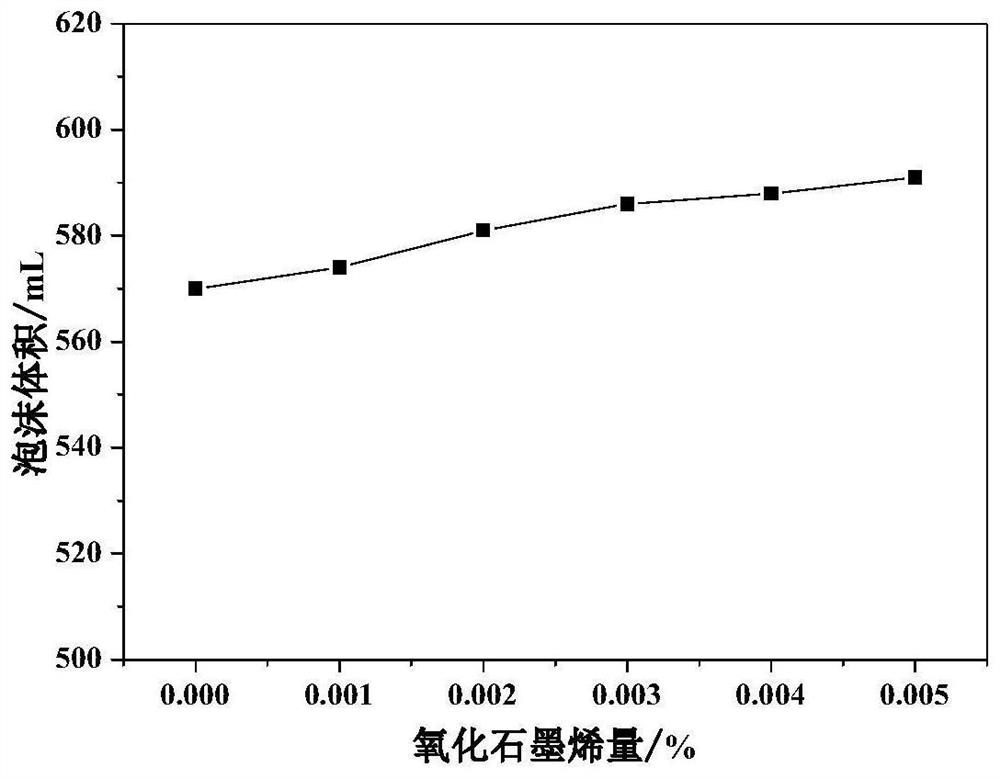

[0035] Weigh 0.001g of graphene oxide nanosheets and fully ultrasonically disperse them in 99.7g of simulated formation ionic water (salinity 20000ppm), then add 0.3g of sodium dodecylbenzene sulfonate, and magnetically stir for 10min to obtain the foaming agent concentration 0.3wt%, the graphene oxide nanosheet concentration is 0.001wt% of the foaming system formula. Then adopt the Waring-Blender method, stir at 30°C and 2700r / min for 3min for foaming, and then record the foaming volume, liquid separation half-life and foam half-life. After the foam completely collapses and disappears, take 5mL of the foaming system and an equal volume of crude oil in a quartz tube to test the emulsification performance.

Embodiment 2

[0037] Weigh 0.002g of graphene oxide nanosheets and fully ultrasonically disperse them in 99.7g of simulated formation ion water (salinity 20000ppm), then add 0.3g of sodium dodecylbenzene sulfonate, and magnetically stir for 10min to obtain the foaming agent concentration 0.3wt%, graphene oxide nanosheet concentration of 0.002wt% of the foaming system formula. Then adopt the Waring-Blender method, stir at 30°C and 2700r / min for 3min for foaming, and then record the foaming volume, liquid separation half-life and foam half-life. After the foam completely collapses and disappears, take 5mL of the foaming system and an equal volume of crude oil in a quartz tube to test the emulsification performance.

Embodiment 3

[0039] Weigh 0.003g of graphene oxide nanosheets and fully ultrasonically disperse them in 99.7g of simulated formation ion water (salinity 20000ppm), then add 0.3g of sodium dodecylbenzenesulfonate, and stir magnetically for 10min to obtain the foaming agent concentration 0.3wt%, the graphene oxide nanosheet concentration is 0.003wt% of the foaming system formula. Then adopt the Waring-Blender method, stir at 30°C and 2700r / min for 3min for foaming, and then record the foaming volume, liquid separation half-life and foam half-life. After the foam completely collapses and disappears, take 5mL of the foaming system and an equal volume of crude oil in a quartz tube to test the emulsification performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com