Method for adjusting optical axis parallelism of fine and rough fields of view

An adjustment method and parallel technology, applied in the direction of position/direction control, control/regulation system, non-electric variable control, etc., can solve the problems of large limitations of the adjustment method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] A method for adjusting the optical axis parallelism of the coarse and fine fields of view of the present invention is introduced below in conjunction with the accompanying drawings and embodiments:

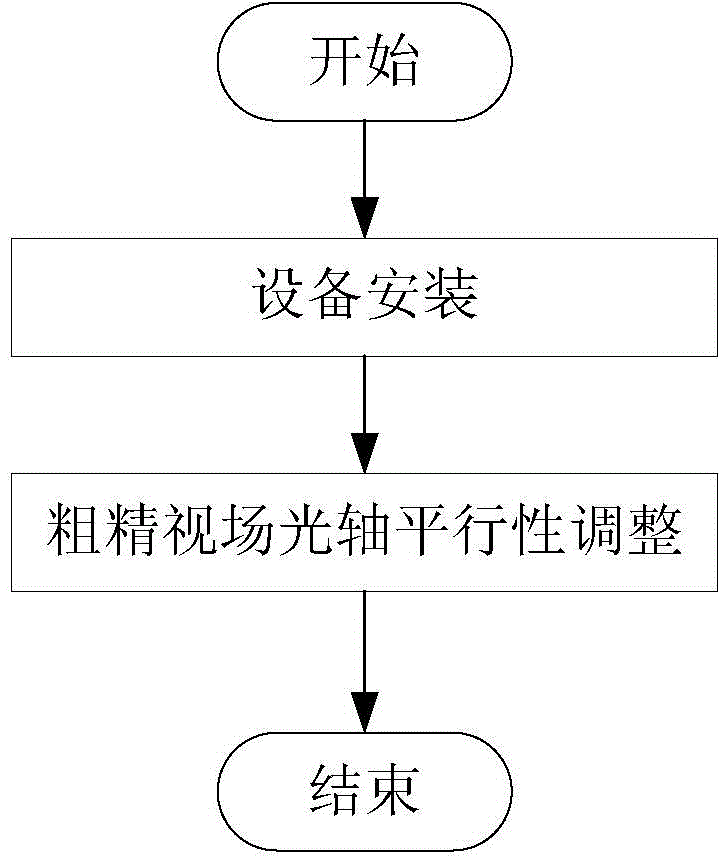

[0031] Such as figure 1 As shown, a method for adjusting the parallelism of the optical axis of the coarse and fine fields of view includes the following steps:

[0032] The first step: install the equipment;

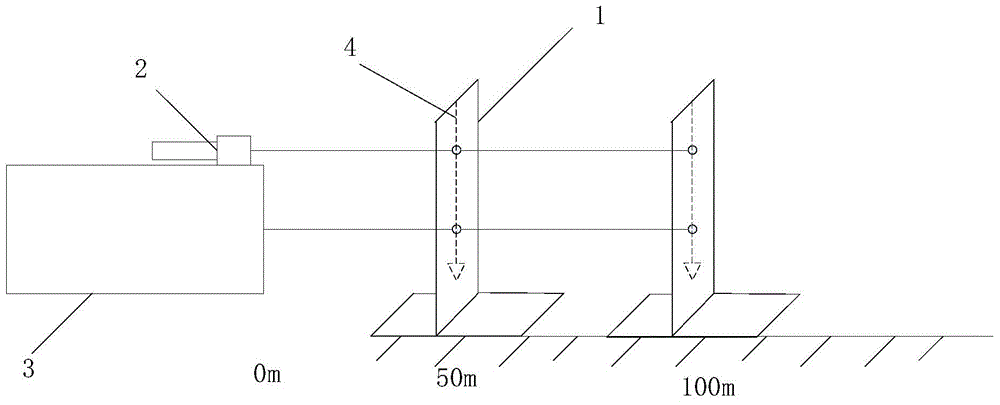

[0033] Such as figure 2 As shown, two target screens 1 are placed at different distances from the optical system, and a vertical indicator 4 is installed on the target screen closer to the optical system. In this embodiment, the optical system for providing a fine field of view adopts a Cassegrain telescopic system, and the laser beam is reflected by the Cassegrain secondary mirror to reach the primary mirror and then exits from the primary mirror. The optical system that provides the coarse field of view is a televised sighting telescope 2 , and the target scree...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com