Light ray parallel adjusting device and method

A light and laser technology, applied in the field of high-precision adjustment of parallelism between light rays, can solve the problems of expensive pentagonal prisms and difficulty in parallelism, and achieve low cost, high adjustment accuracy, and simple adjustment devices and methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

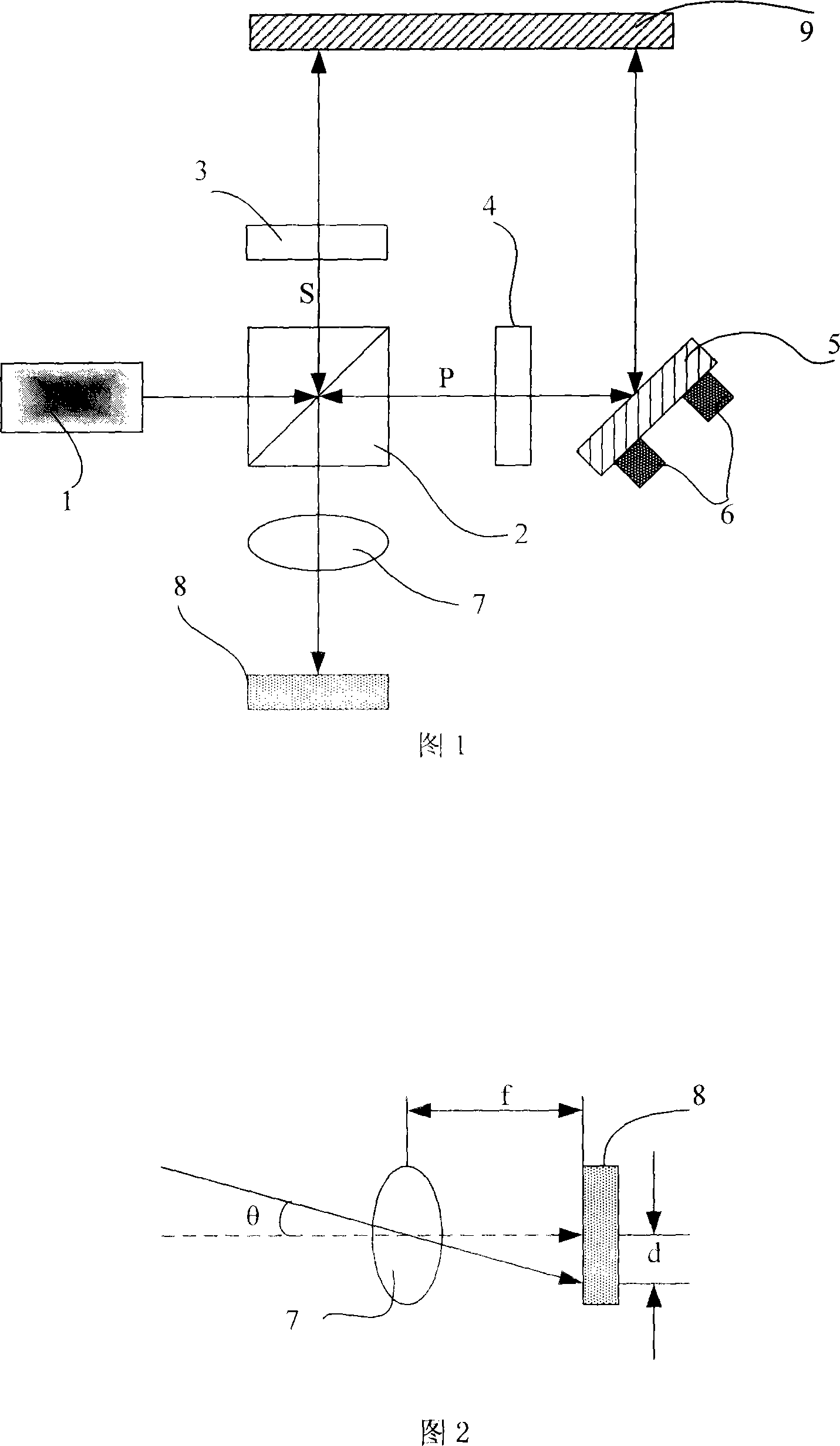

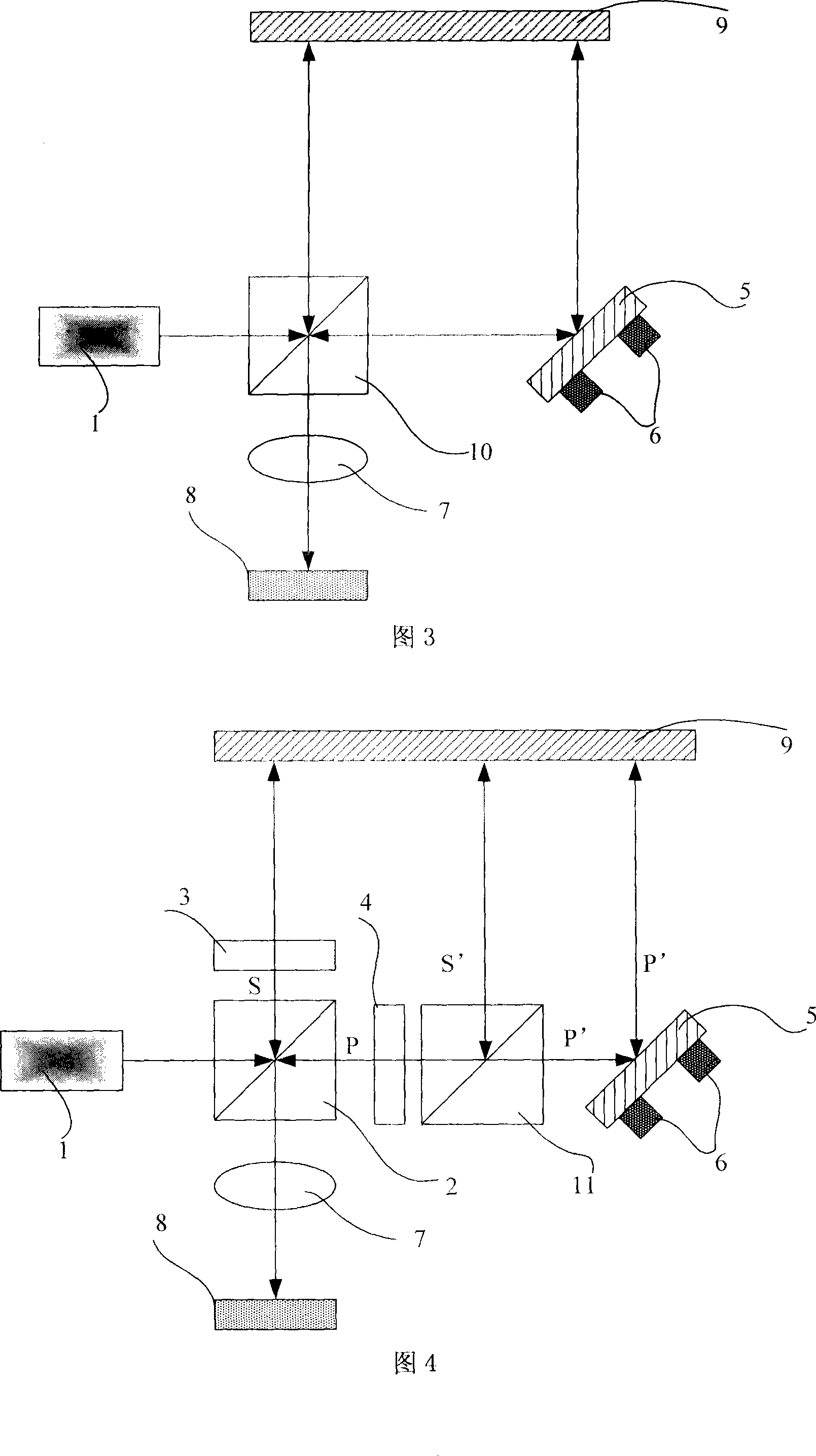

[0031] Further illustrate the present invention below in conjunction with accompanying drawing.

[0032] Figure 1 shows the principle device for adjusting two beams of parallel light. The collimated laser 1 emits stable laser light and splits it through the polarization beam splitter 2, which is divided into vertical linear polarization S and parallel linear polarization P lasers. Block the transmitted light P of the polarization beam splitter with a cardboard, so that the vertical linearly polarized laser S passes through a λ / 4 wave plate 3, becomes circularly polarized light, and is incident on a plane mirror 9, wherein the λ / 4 wave plate 3 The fast axis is at 45° to the S polarization direction. Adjust the plane reflector 9 so that the circularly polarized light returns in reverse and passes through the λ / 4 wave plate 3 for the second time. At this time, the light changes from circularly polarized light to linearly polarized light, but the polarization direction is rotated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com