Separation method

A separation and rectification separation technology, applied in the field of separation, can solve the problems of insignificant complexity, high investment cost and operation cost, temperature fluctuation at the bottom of the demethanizer, etc., and achieve great flexibility, effective method flow, process technically simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

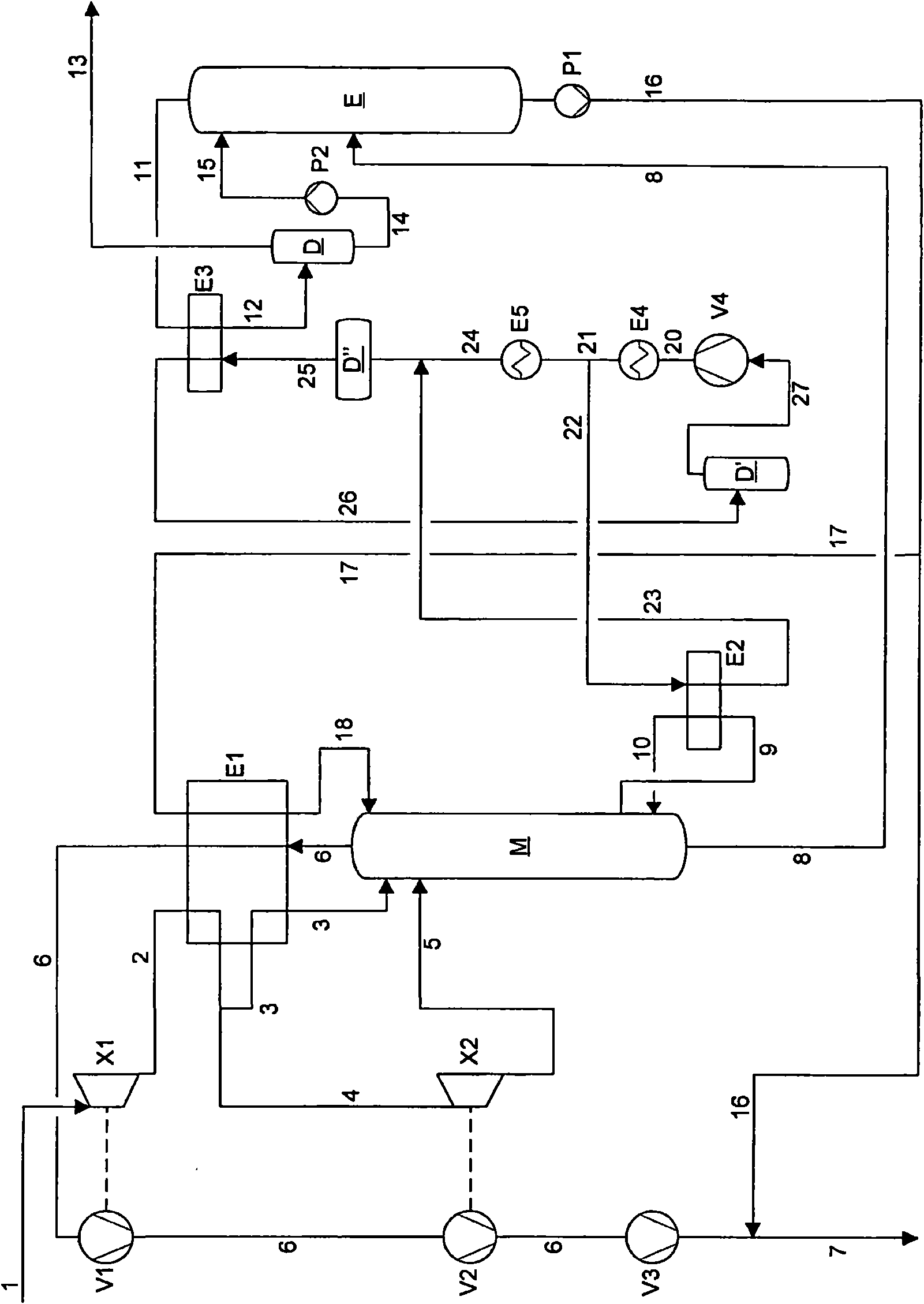

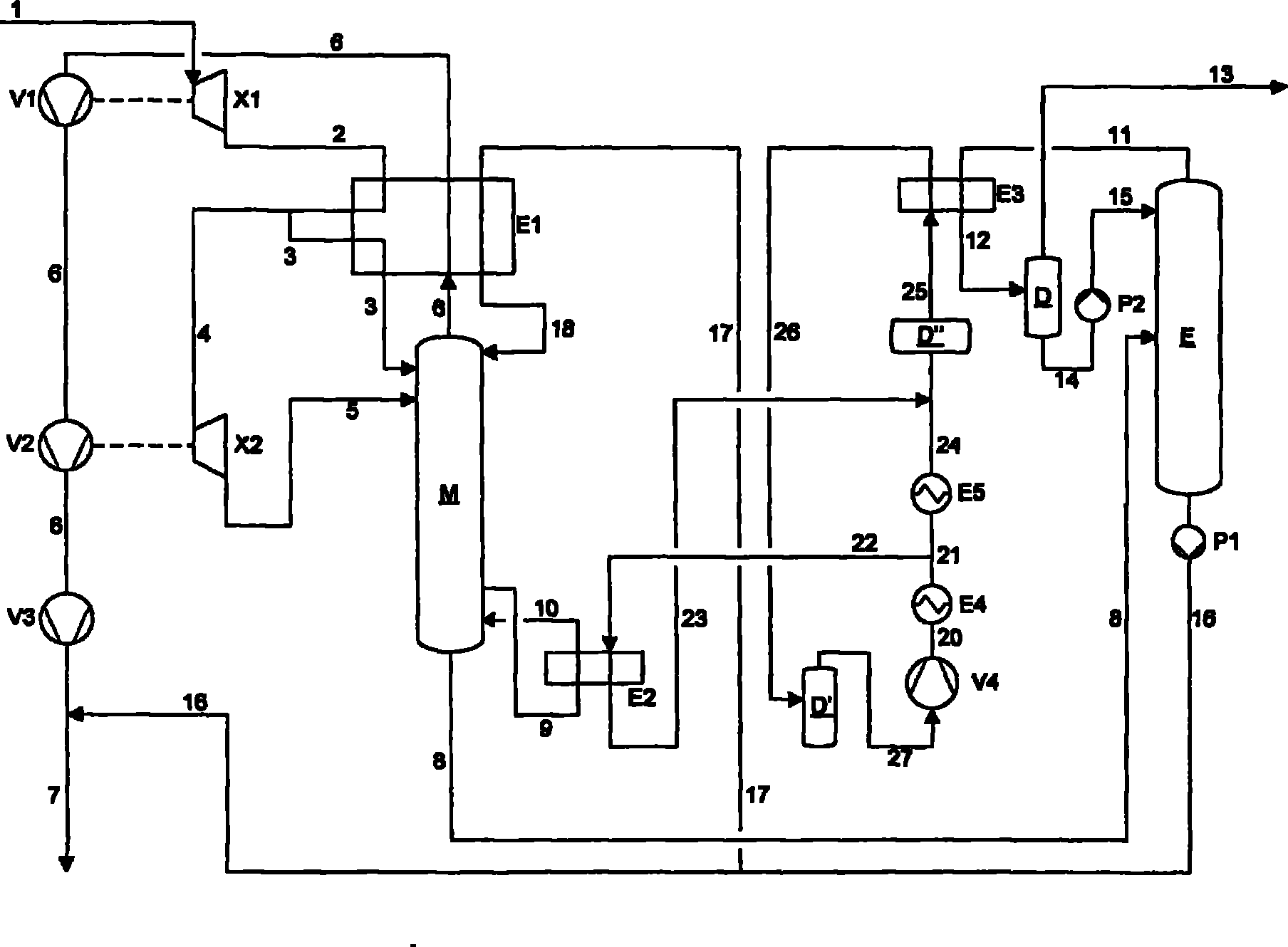

[0016] The hydrocarbon-rich fraction is sent via line 1 to the first expansion turbine X1. The pressure of the hydrocarbon-rich fraction is preferably between 70 and 120 bar. If necessary, the hydrocarbon-rich fraction is subjected to a pretreatment not shown in the figures, in which undesired components such as water and glycols are removed.

[0017] The hydrocarbon-rich fraction depressurized in the first expansion turbine X1 is fed via line 2 to heat exchanger E1 where it is cooled against itself. After discharge from the heat exchanger E1 , the hydrocarbon-rich fraction is divided into two partial streams 3 and 4 . The first partial stream 3 is fed to the top of the demethanizer M after further cooling and complete condensation in the heat exchanger E1.

[0018] The second partial stream 4 is decompressed in the second expansion turbine X2 and then likewise fed via line 5 to the top region of the demethanizer M. In this case, the entry point of the second partial flow i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com