Parallelism detecting device and film sticking machine

A detection device and a parallelism technology, which are applied in the fields of parallelism detection devices and film lamination machines, can solve the problems of difficulty in detecting the parallelism of a substrate and a film layer, and achieve the effect of improving blocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

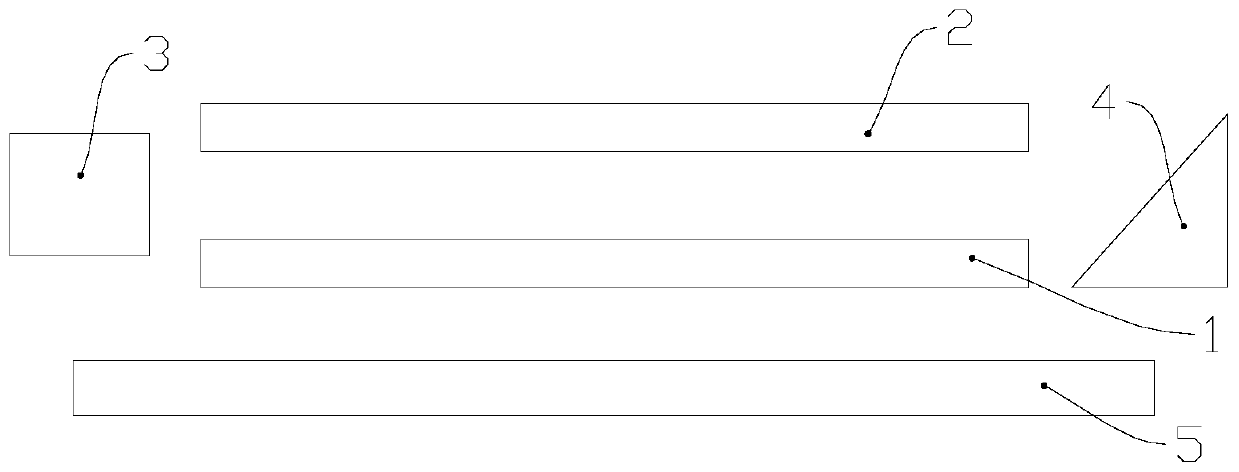

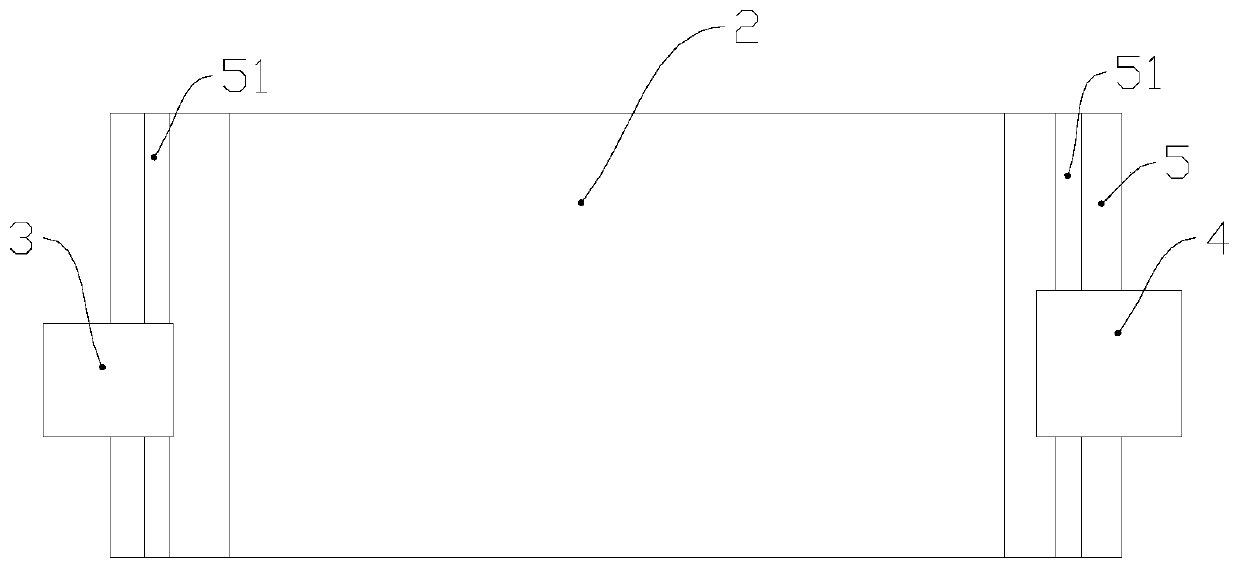

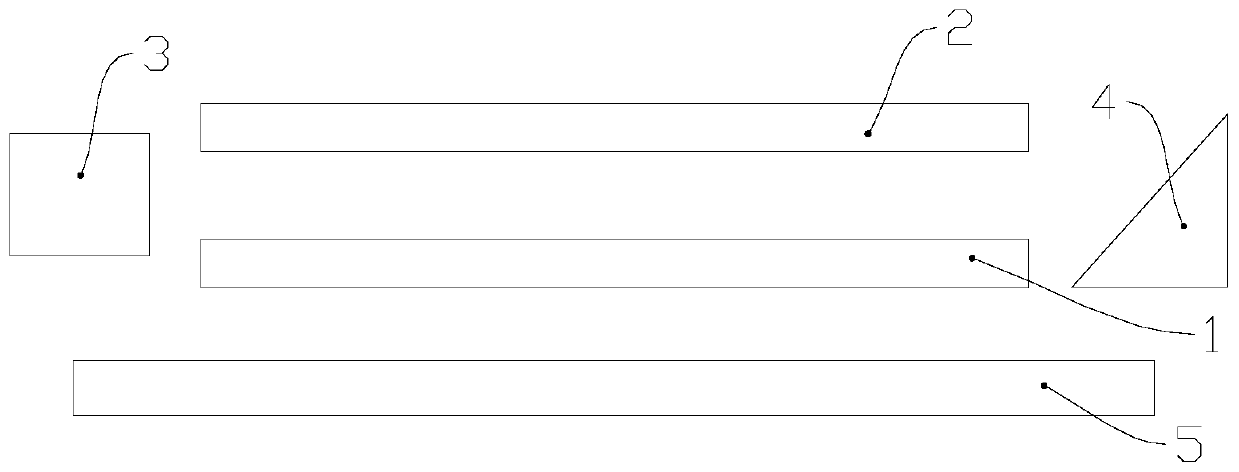

[0066] Further, as a specific embodiment of the film laminating machine provided by the present invention, it also includes a second driving mechanism, which can drive the second fixing device to adjust the angle of the film layer 2, so as to facilitate the adjustment of the substrate 1 and the film layer 2. The parallelism between them improves the adjustment accuracy and adjustment efficiency.

[0067] Specifically, the second drive mechanism is connected to the TOF rangefinder 3 with a signal, and the second drive mechanism can adjust the relative relationship between the film layer 2 and the film layer 2 according to the parallelism information between the substrate 1 and the film layer 2 detected by the TOF rangefinder 3. Parallelism of substrate 1.

[0068] Optionally, the second driving mechanism is an air cylinder.

[0069] Further, as a specific embodiment of the film laminating machine provided by the present invention, it also includes a glue injection device, whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com