Automatic laser welding device for fibre-optical active component

A laser welding and active device technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of poor device performance consistency, slow speed, low yield, etc., to eliminate angular deviation and have great flexibility , the effect of strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

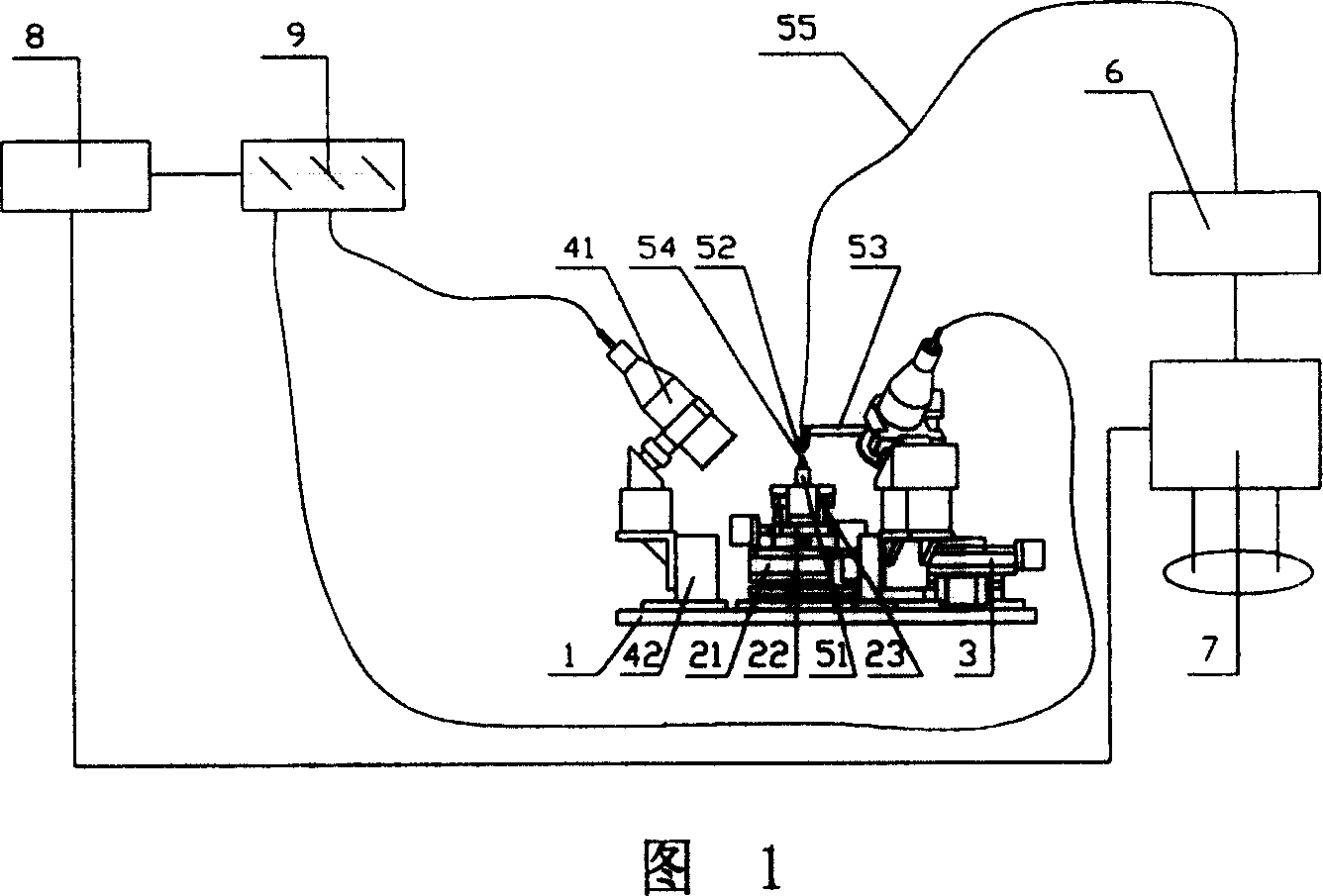

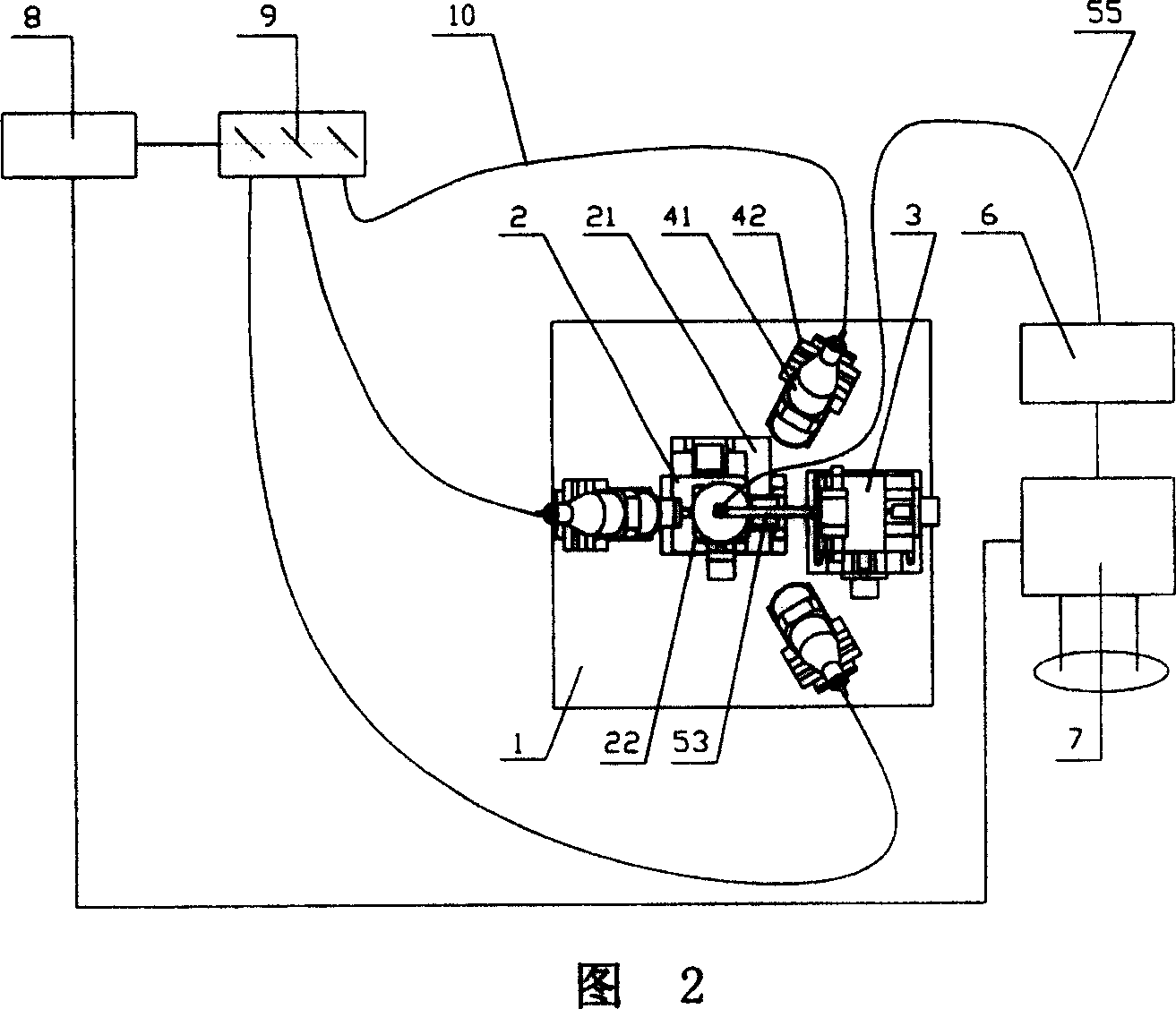

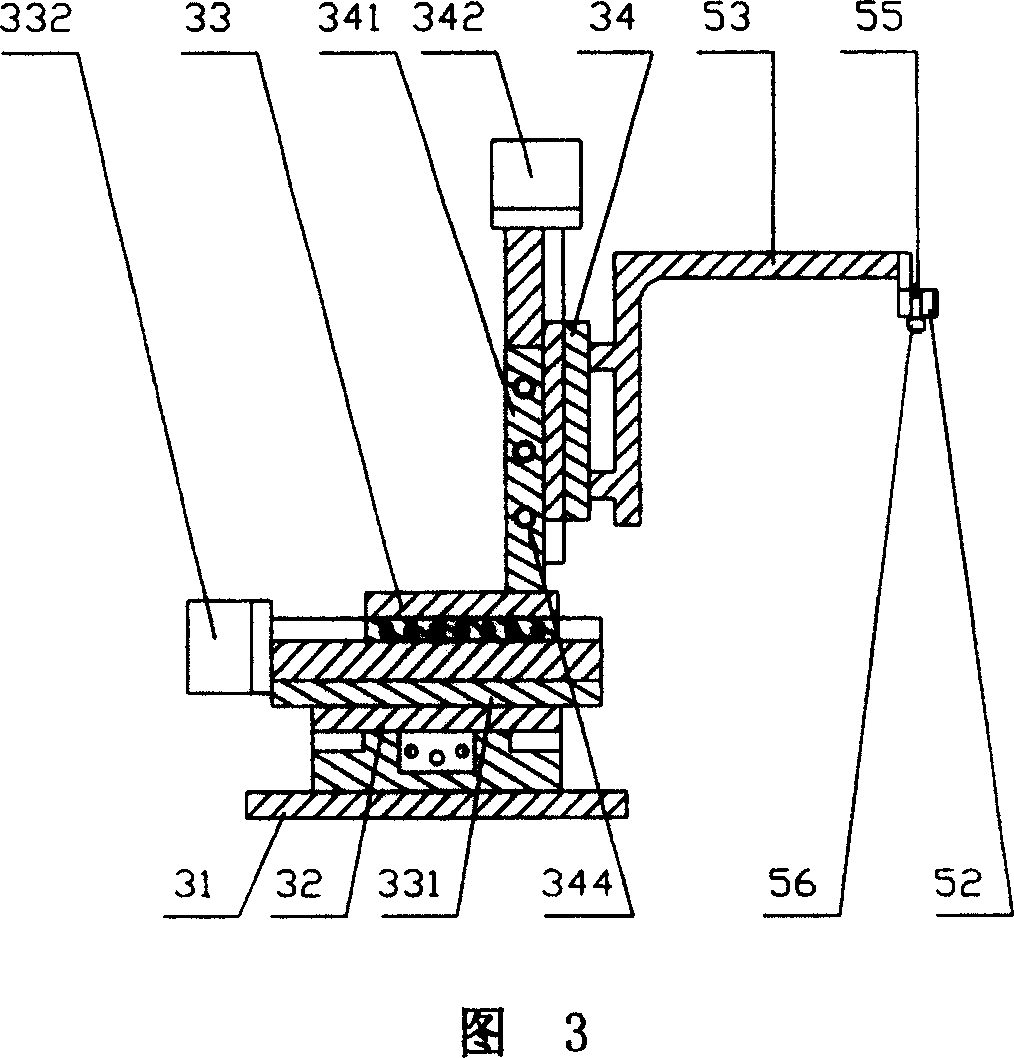

[0071] As shown in Figures 1 and 2, the automatic laser welding device for optical fiber active devices of the present invention includes a workbench 1, a control unit, a laser welding mechanism and a precision docking mechanism, and both the laser welding mechanism and the precision docking mechanism are installed on the workbench 1 . The precision docking mechanism includes a three-degree-of-freedom optical fiber position adjustment mechanism 3 and a four-degree-of-freedom light source device position adjustment mechanism 2. Relative position adjustment of five degrees of freedom of optical fiber. The laser welding mechanism includes a solid-state laser 8, a beam splitter 9, three identical transmission optical fibers 10, three identical focusing mirrors 41 and a focusing mirror adjustment mechanism 42, and the three focusing mirro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle of incidence | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com