Intermediate-temperature-sensitized emulsion explosive and preparation method thereof

An emulsion explosive, medium temperature technology, applied in the direction of explosives, etc., can solve the problems of destroying sensitized bubbles and easy inversion of the oil phase material of emulsion explosives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

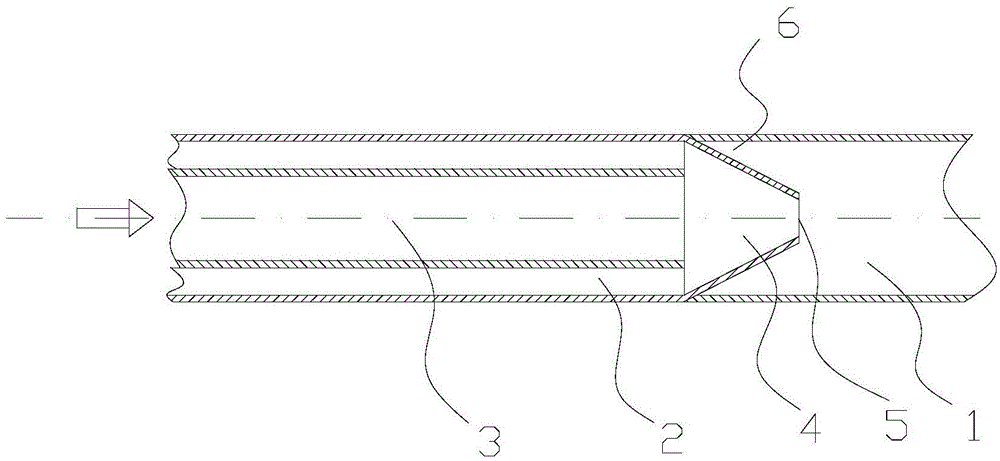

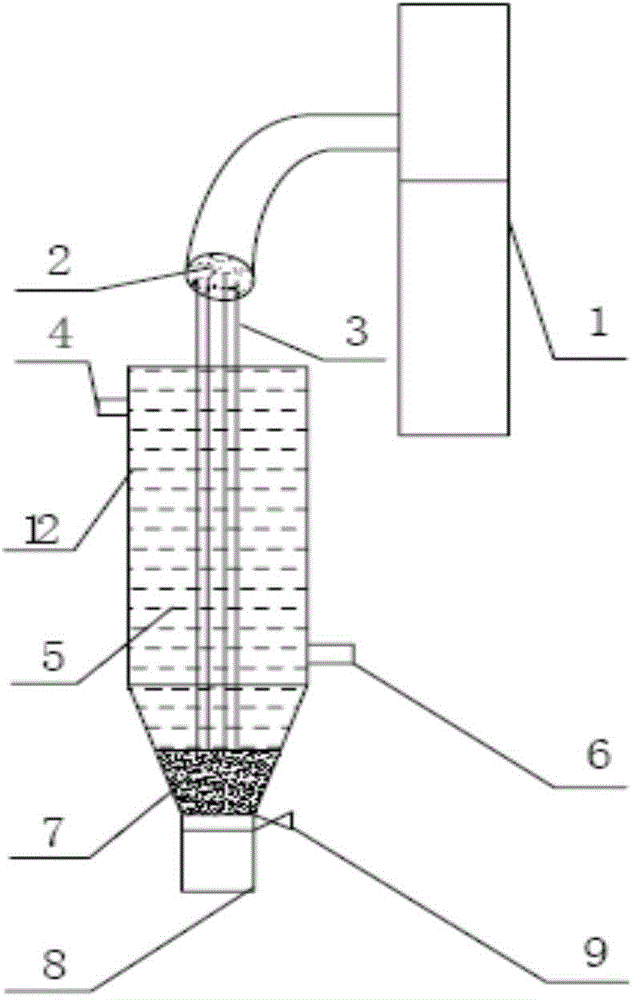

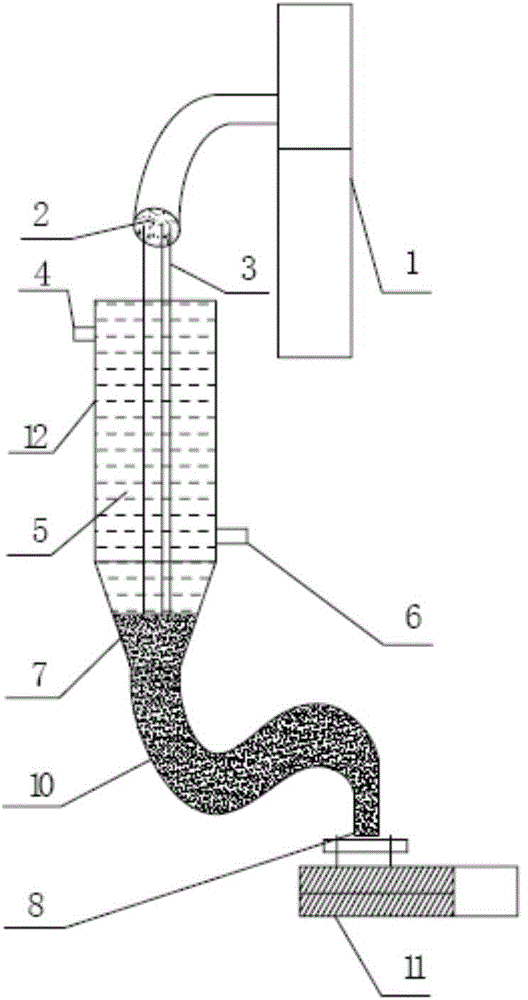

Method used

Image

Examples

Embodiment 1

[0071] Embodiment 1: prepare medium temperature sensitized emulsion explosive I on the production line of the present invention

[0072] (1) emulsifying agent 1, explosive compound wax, geomineral wax, microcrystalline wax are formulated into 6.7 kilograms of oil phases in proportions of 2 kilograms, 4 kilograms, 0.45 kilograms, and 0.25 kilograms, and the oil phases are heated to 85° C. for use; Sodium nitrate, ammonium nitrate, and water are formulated into 90.3 kg of water phase according to the ratio of 8.1 kg, 70.5 kg, and 11.7 kg, and the water phase is heated to 105°C for use; the weight ratio of sodium nitrite and ammonium nitrate is 1:1 The proportion of the sensitizer with a concentration of 8% is prepared for use at room temperature;

[0073]The emulsifier I is a mixture of sorbitan fatty acid ester and lecithin in a weight ratio of 1:1; the explosive composite wax is the explosive composite wax produced by Maoming Xinhua Yue Petrochemical Co., Ltd. MF-1; the miner...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com