Reversed deformation treatment process before welding of H-shaped steel structures

A technology for processing technology and H-shaped steel, which is applied in welding equipment, manufacturing tools, arc welding equipment, etc., to achieve the effects of reducing processing costs, eliminating quality problems, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The content of the present invention will be described below in conjunction with specific embodiments.

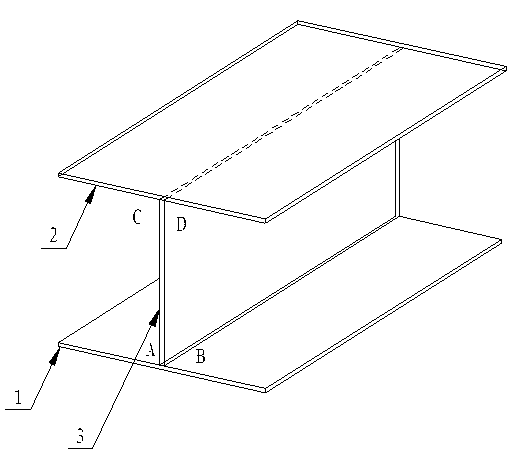

[0019] like figure 1 Shown is a schematic diagram of the H-shaped steel structure of the present invention. The H-shaped steel structure described in the present invention comprises: the lower wing plate 1, the upper wing plate 2 and the web 3, the lower wing plate 1, the upper wing plate 2 and the web plate 3 are all steel plates of a certain size, and are composed of “H” "Type welded. When the lower flange 1, the upper flange 2 and the web 3 are welded, four different fillet welds A, B, C, D are formed. Due to the different welding sequence, the local temperature and degree of deformation of the lower flange 1, upper flange 2 and web 3 are also different during welding, so the final H-shaped steel structure is easily deformed, which is different from the actual requirements. Big difference.

[0020] In order to realize the ideal H-shaped steel structure describ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com