Cigarette bundle filling device of side-opening type molded cigarette box

A filling device and side-opening technology, applied in the field of packaging paper cigarettes, can solve the problems of slow production speed, low production efficiency, deformation of cigarettes and cigarette cases, etc., and achieve the effects of improving production efficiency, simple structure and eliminating quality problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The structure of the cigarette bundle filling device of the side-opening shaped cigarette case and its working process for automatically filling cigarette bundles will be described in detail below in conjunction with the accompanying drawings.

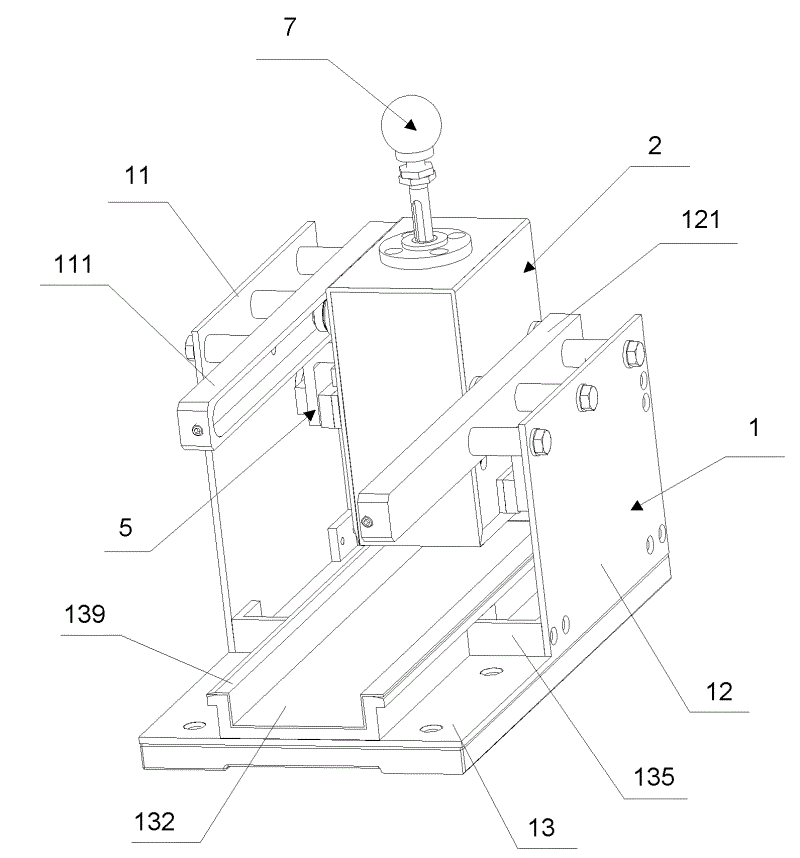

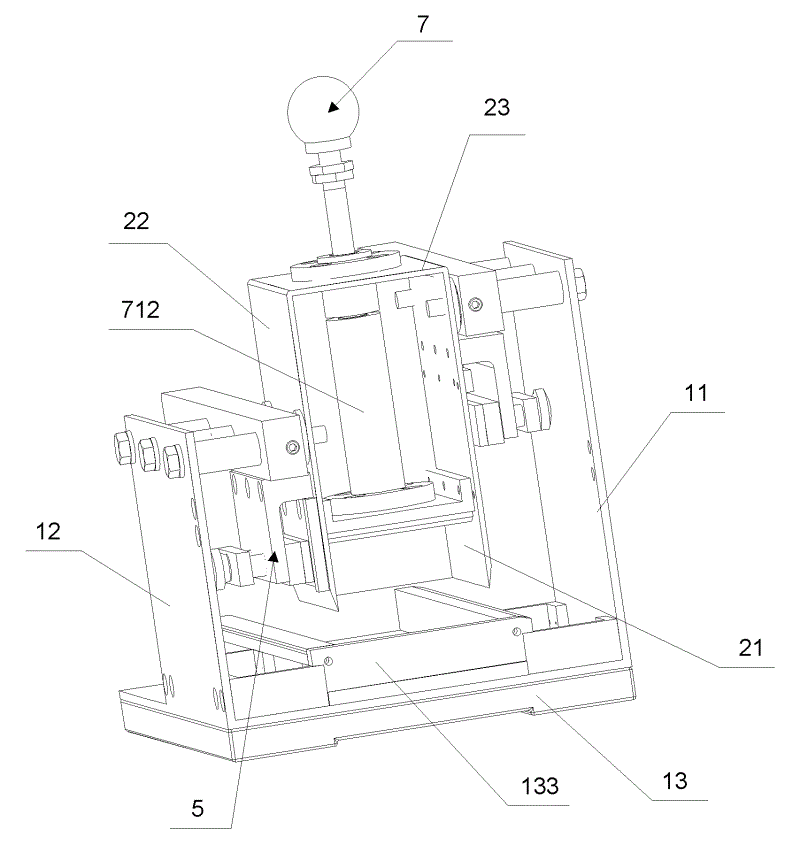

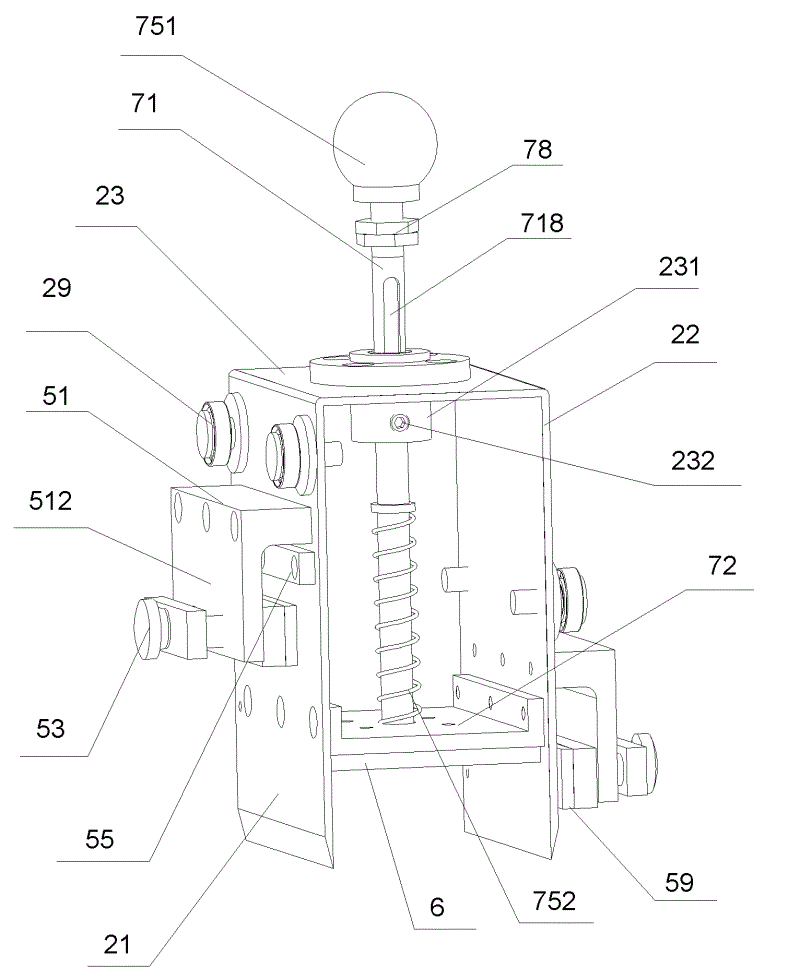

[0035] Such as figure 1 and figure 2 As shown, the cigarette bundle filling device of the side-opening shaped cigarette case of the present embodiment includes a support frame 1 and a semi-open mold case 2 erected on the support frame 1; One side plate 21 and the second side plate 22 , and a top plate 23 connected to the upper ends of the first side plate 21 and the second side plate 22 . The cigarette bundle and the side-opening formed cigarette case enter the working position from the opposite direction. For the convenience of description, the side where the side-opening formed cigarette case enters the working position is taken as the front end, that is, figure 1 The side shown in is the front end, and the side where the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com