Soft floating roof method for reducing evaporation of liquid fuel storage tank through hollow plastic product

A technology for plastic products and liquid fuels, applied in containers, packaging, transportation and packaging, etc., can solve the problems of limited minimum descending height, limited lifting speed, and high cost of floating roofs, reducing the risk of explosion and evaporation loss, The effect of suppressing volatilization and reducing evaporation loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The preparation method includes the following steps: first stirring, mixing, extruding, and granulating the masterbatch and the flame retardant, making a hemisphere through an injection molding process, and then combining the two hemispheres into a hollow covering sphere by welding; or The masterbatch and the flame retardant are stirred and mixed, then melted, and the hollow covering ball is directly obtained through the hollow blow molding process.

[0019] The hollow plastic product is not only resistant to non-polar petroleum-based fuels, but also resistant to polar dangerous chemicals such as methanol gasoline, ethanol gasoline, acetone, ethyl acetate and the like.

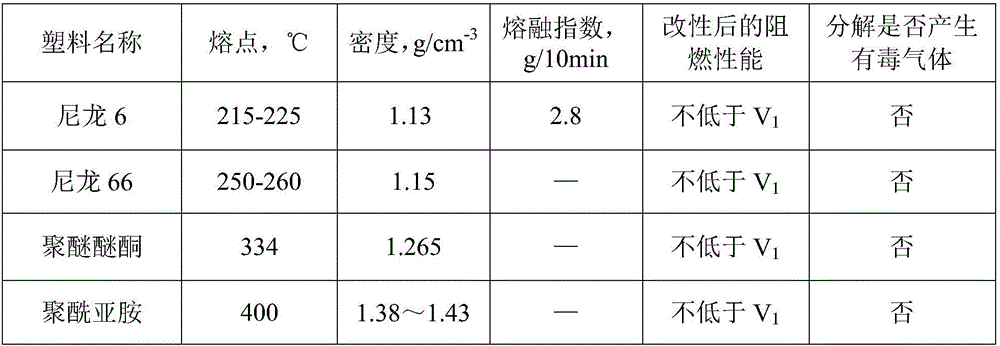

[0020] The plastic matrix material involved in the present invention includes nylon 6, nylon 66, polyetheretherketone PEEK and polyimide PI, and their modified products. Its specific performance requirements are as follows.

[0021]

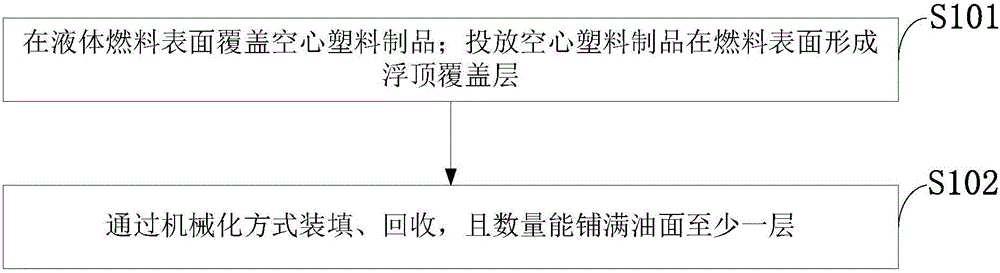

[0022] Such as figure 1 As shown, the soft floating roof method ...

Embodiment 1

[0027] Use a cylindrical container with a diameter of 26cm to simulate an oil tank, put a certain volume of No. 93 motor gasoline into the container, and lay a Φ38mm×1.8mm nylon 66 covering ball with a certain thickness above the liquid surface. Fill another container with the same quality of oil, without putting in the hollow covering ball, as a blank experiment. Put the two in the same environment to let them volatilize naturally, and use a high-precision balance to obtain the volatilization of the oil after different times by weighing. Experimental data show that, compared with the oil without covering treatment, the volatilization loss of oil in the experimental group with covering balls can be reduced by 60%.

Embodiment 2

[0029] Use a cylindrical container with a diameter of 26cm to simulate an oil tank, put a certain volume of ethanol gasoline into the container, and lay a polyimide covering ball with a certain thickness of Φ40mm×1.0mm above the liquid surface. Fill another container with the same quality of oil, without putting in the hollow covering ball, as a blank experiment. Put the two in the same environment to let them volatilize naturally, and use a high-precision balance to obtain the volatilization of the oil after different times by weighing. Experimental data shows that, compared with the oil without covering treatment, the volatilization loss of oil in the experimental group with covering balls can be reduced by 65%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com