Preparing method for 1-hexyl-3-methylimidazole hexafluorophosphate ionic liquid and fire resistant hydraulic oil with the same

A technology of hexafluorophosphate and methyl imidazole, which is applied in base materials, petroleum industry, organic chemistry, etc., can solve problems such as poor lubrication performance, inability to meet the requirements of hydraulic systems, and limitations of use scope, and achieve excellent lubrication performance, Biodegradable material suitability, effect of low evaporation loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

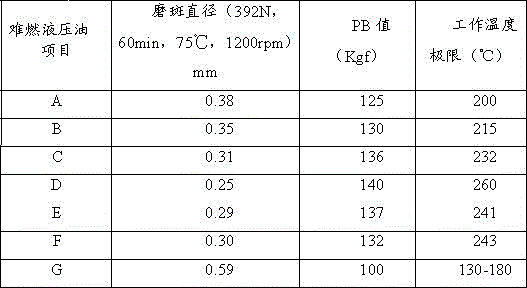

Examples

Embodiment 1

[0028] A kind of green and environment-friendly fully synthetic flame retardant hydraulic oil, which specifically includes 80 parts by mass of 1-hexyl-3-methylimidazolium hexafluorophosphate ionic liquid, 0.1 part of dialkyl zinc dithiophosphate, 0.01 part Diphenylamine, 0.01 part of benzotriazole, 0.1 part of polymethyl acrylate and 0.0001 part of higher alcohol fatty acid ester compound, mix the above components uniformly and stir to obtain flame retardant hydraulic oil A.

Embodiment 2

[0030] A kind of green environment-friendly fully synthetic flame retardant hydraulic oil specifically comprises 85 parts of 1-hexyl-3-methylimidazolium hexafluorophosphate ionic liquid, 0.2 parts of dialkyl zinc dithiophosphate, 0.02 parts Diphenylamine, 0.02 part of benzotriazole, 0.1 part of polymethyl acrylate and 0.0001 part of higher alcohol fatty acid ester compound, mix the above components evenly and stir to obtain flame retardant hydraulic oil B.

Embodiment 3

[0032] A kind of green and environment-friendly fully synthetic flame retardant hydraulic oil, which specifically includes 90 parts by mass of 1-hexyl-3-methylimidazolium hexafluorophosphate ionic liquid, 0.3 parts of dialkyl zinc dithiophosphate, 0.01 parts Diphenylamine, 0.03 part of benzotriazole, 0.2 part of polymethyl acrylate and 0.0001 part of higher alcohol fatty acid ester complex, mix the above components uniformly and stir to obtain flame retardant hydraulic oil C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com