Automatic welding device of box-type steel member

A technology of automatic welding and steel components, applied in auxiliary devices, welding equipment, auxiliary welding equipment and other directions, can solve the problems of low work efficiency of manual welding, increase production and processing costs, and large gap in quality level, so as to improve work efficiency and Process quality, eliminate quality problems, prevent outflow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The principles and features of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that the examples given are only used to explain the present invention, and do not constitute a specific limitation to the patent protection scope of the present invention.

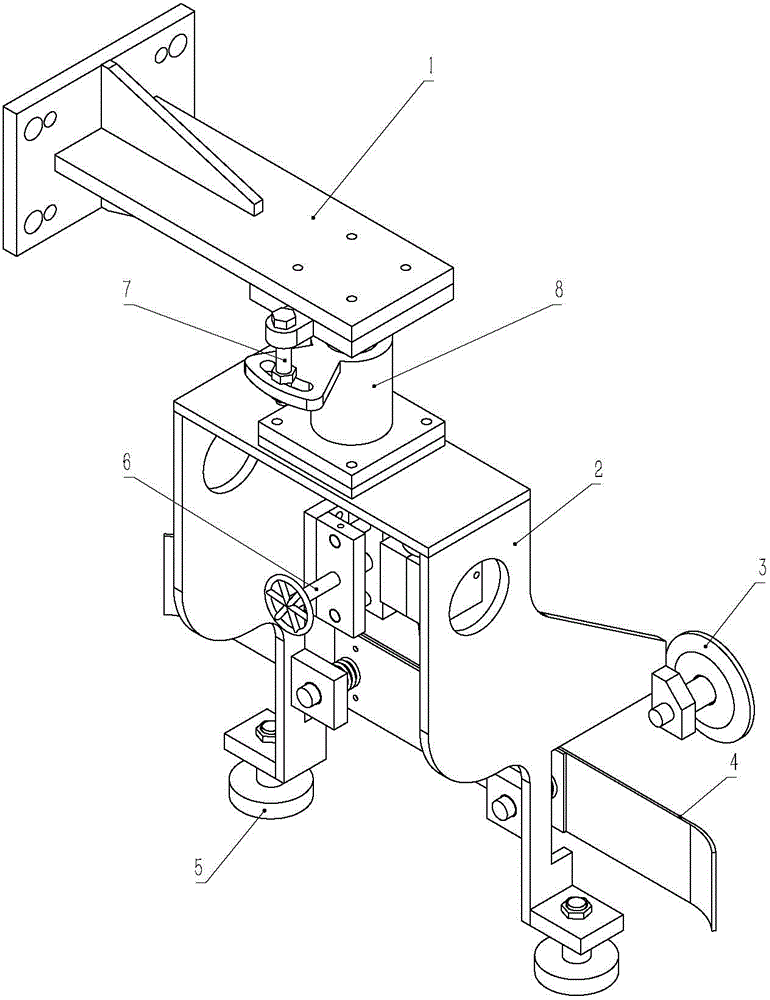

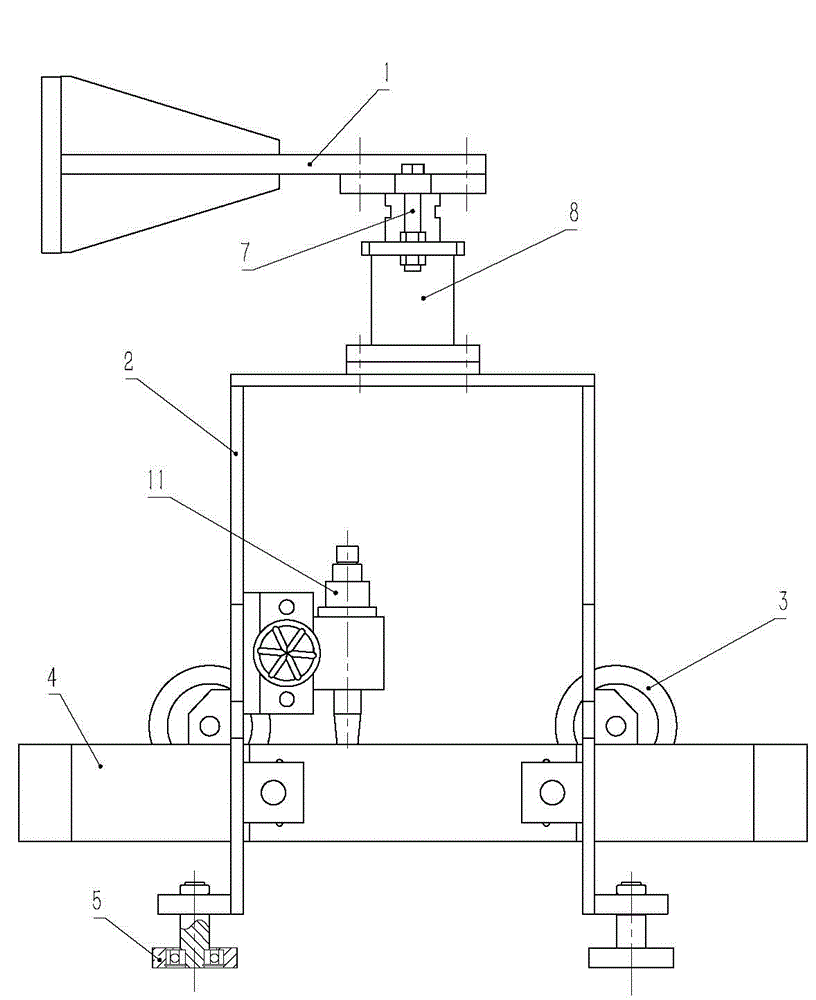

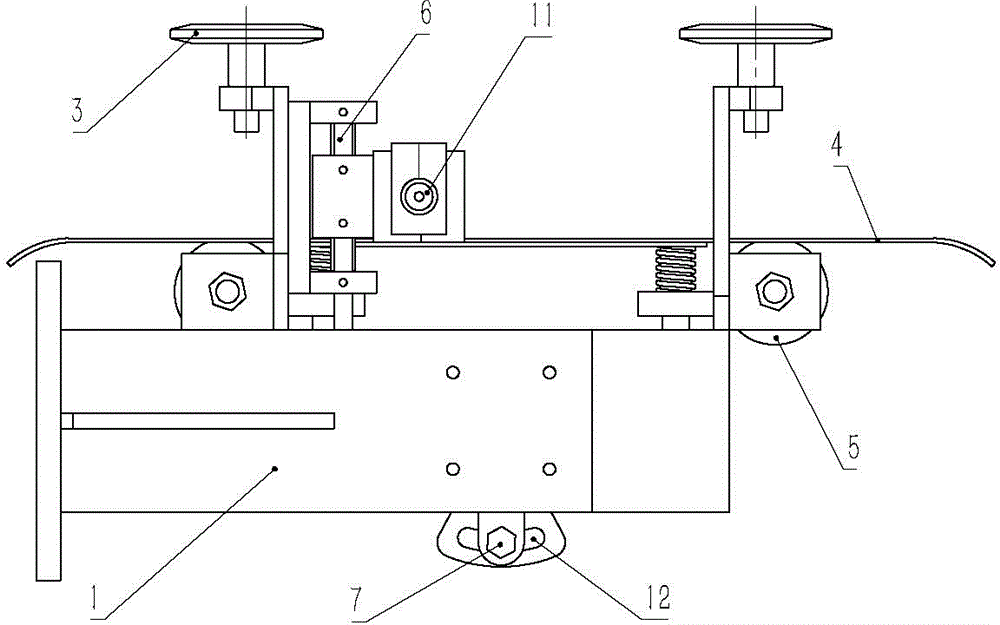

[0014] This automatic welding device for box-type steel components, figure 1 — Figure 5 shown. It is connected with a fixed screw sleeve 8 by bolts at the upper end of the bracket 2, and a vertical shaft 9 is fixedly connected with the inner hole of the fixed screw sleeve through threads, and the disc at the upper end of the vertical shaft is rotatably placed at the lower end of the cantilever seat 1. In the circular step hole ( image 3 shown). A welding torch 11 is longitudinally connected to the movable seat provided at the middle part of the support 2 . On the outer support of described welding torch, two walking wheels 3 ( figure 2 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com