Patents

Literature

99results about How to "Eliminate test errors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Virtual instrument-based motor control automatic testing system and method for electric automobile

ActiveCN102147619AGuaranteed synchronous samplingAcquisition speed is fastElectric testing/monitoringArea networkPCI eXtensions for Instrumentation

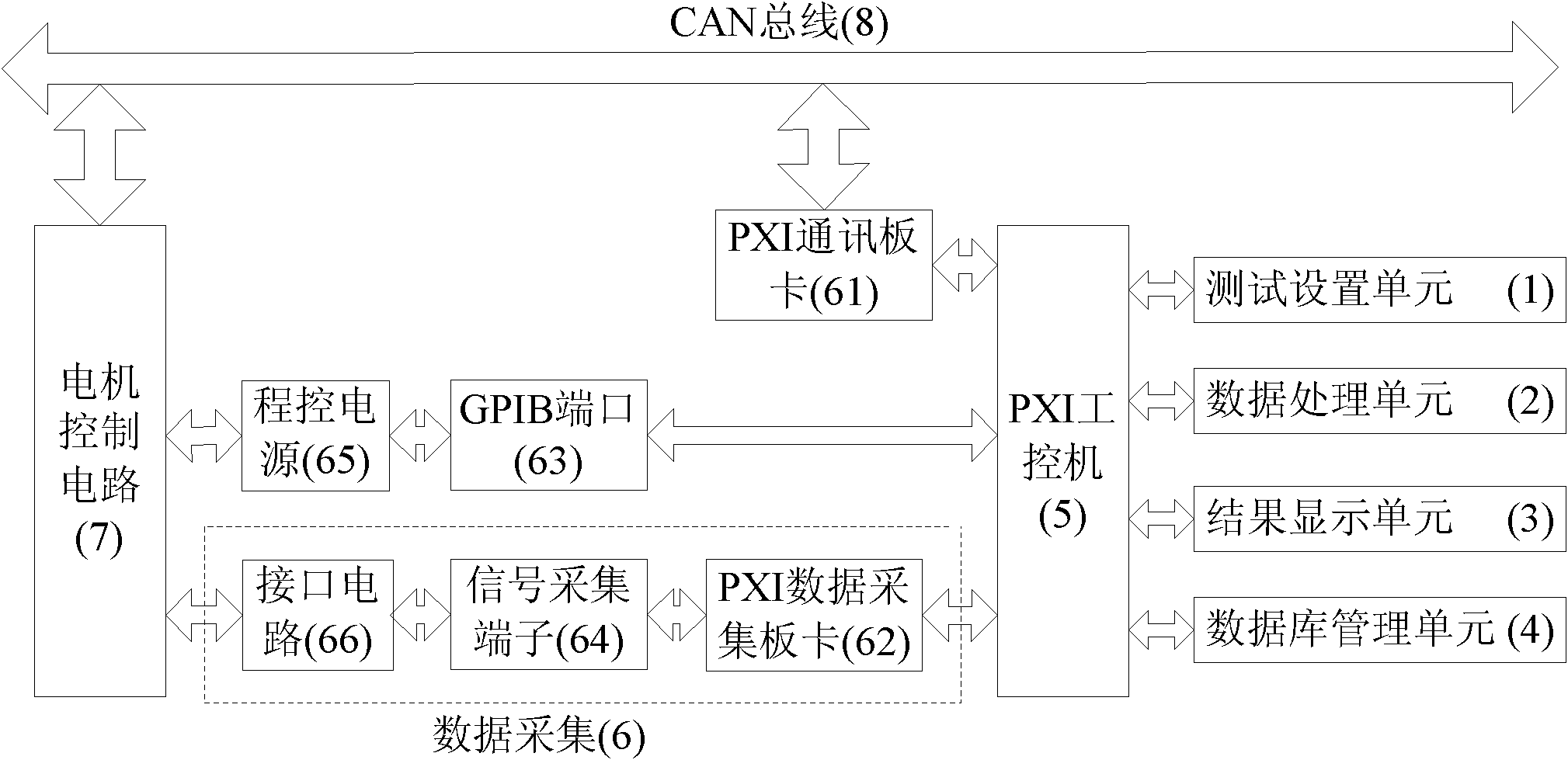

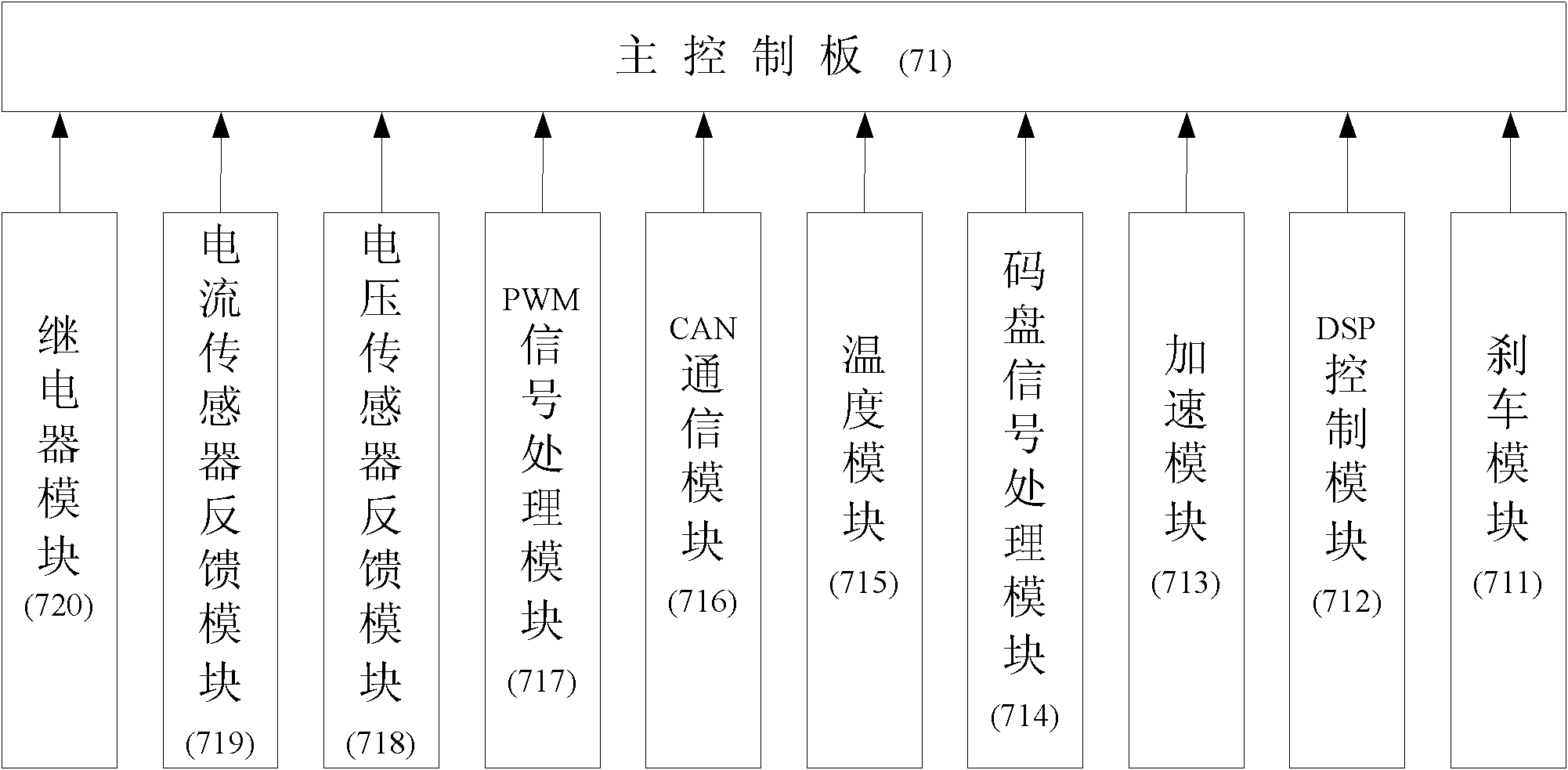

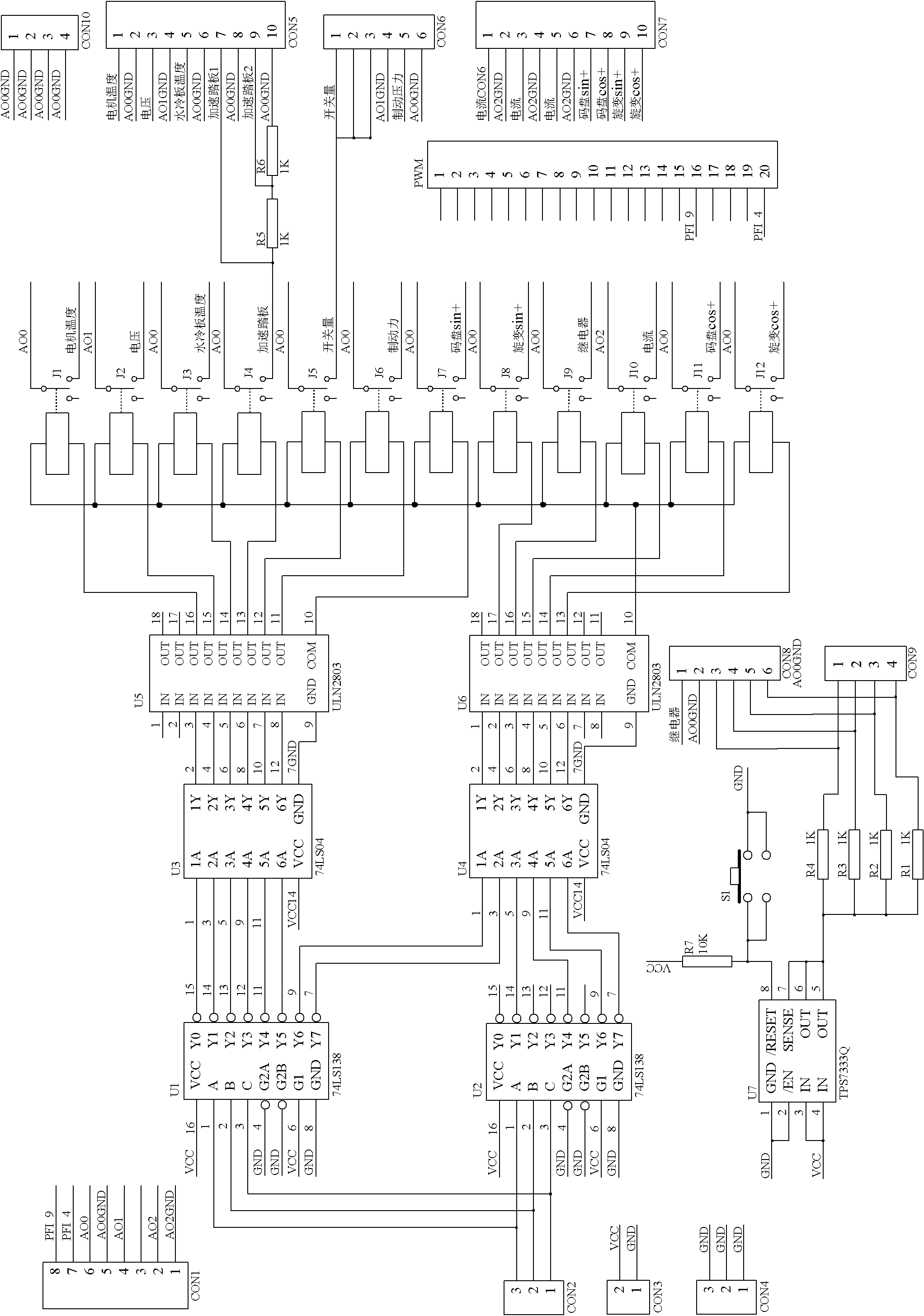

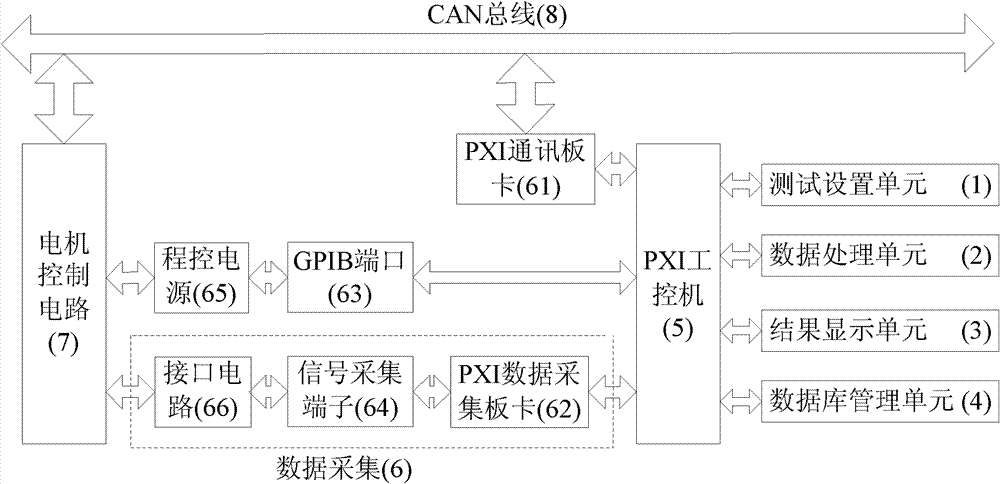

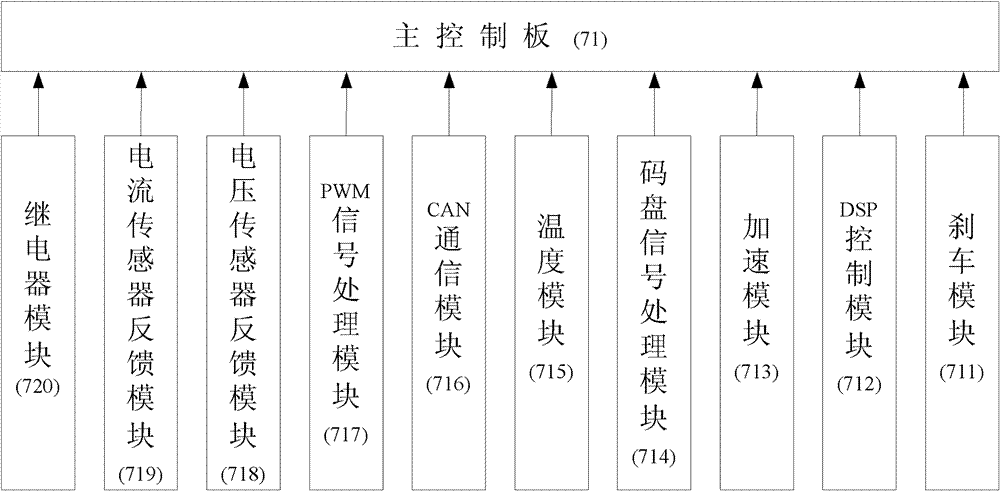

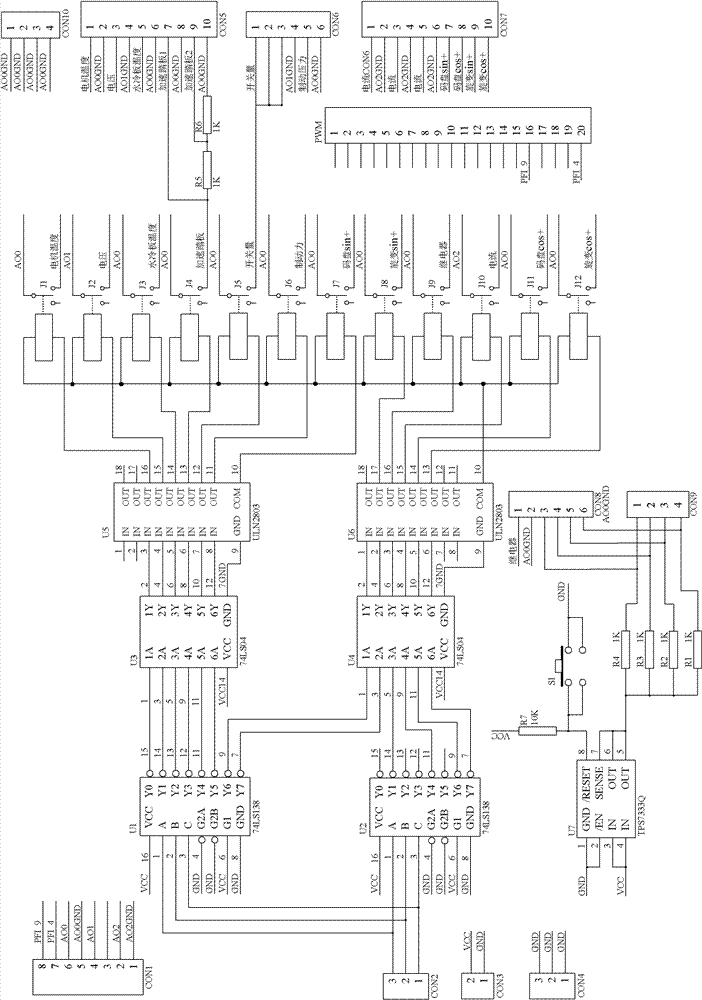

The invention provides a virtual instrument-based motor control automatic testing system and method for an electric automobile, wherein the system comprises an industrial personal computer and a CAN (controller area network) communication bus connected with the industrial personal computer, a test setting unit, a data processing unit, a result display unit and a database management unit which areall connected with the industrial personal computer, a data collecting unit respectively connected with a motor control circuit to be tested and the industrial personal computer, and a PXI (PCI Extensions for Instrumentation) communication card respectively connected with the industrial personal computer and the CAN communication bus; a programmable power supply is connected with the motor control circuit to be tested; and the motor control circuit to be tested is respectively connected with the data collecting unit and the CAN communication bus. The method comprises the steps of: selecting test items and setting parameters; collecting testing signals; analyzing and processing test data; displaying a testing result; and updating and managing a database. By the automatic testing system andmethod, the function detection and the collecting, processing and storing of the testing data of an electric automobile motor control circuit can be completed automatically; the synchronous sampling of the testing data is ensured; the automatic testing system and method have high testing precision and good the repeatability is good; the testing error is reduced; and the automatic level of the detection is improved.

Owner:TIANJIN QINGYUAN ELECTRIC VEHICLE

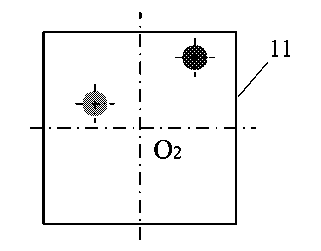

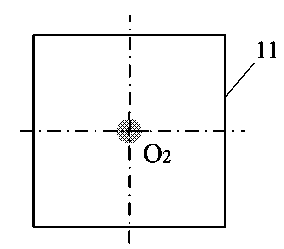

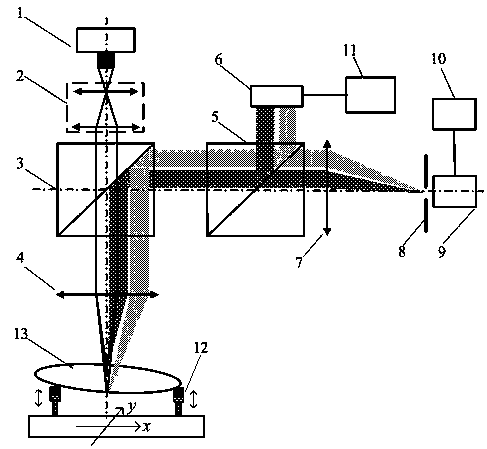

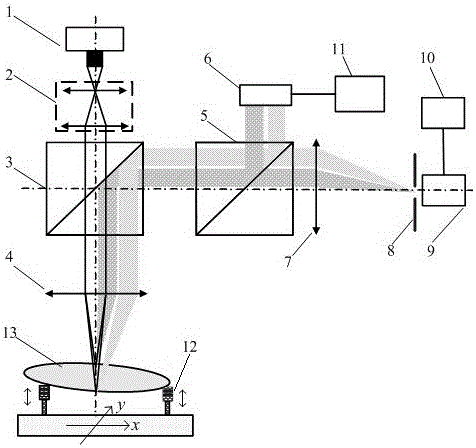

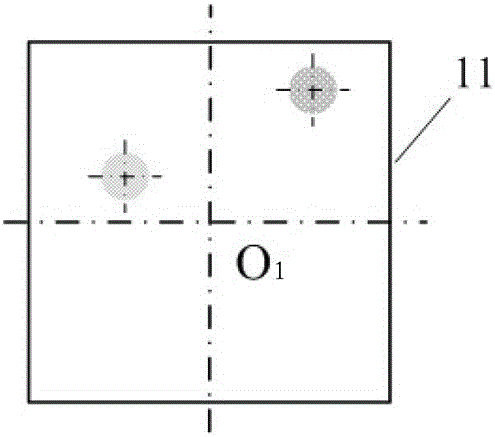

Spectrum confocal type measurement method and device for thickness of center of lens

InactiveCN104061867AHigh coincidenceReduce wasteUsing optical meansMeasurement deviceComputational physics

The invention relates to a spectrum confocal type measurement method and device for the thickness of the center of a lens. An existing method and device have large errors and consume much time when carrying out measurement. The measurement method includes the steps that an area-array cameras and a television image are utilized for assisting in centering, the thickness of the center of the optical lens is measured through the spectrum confocal means, accuracy of the measured thickness is ensured, and accuracy of test results is largely improved. The measurement device is additionally provided with a monitor optical way for the process of measuring the thickness of the lens through the spectrum confocal means, the ratio of overlapping of a centering optical way and a measurement optical way is high, unnecessary hardware waste is reduced, and cost of the measurement device is effectively controlled.

Owner:XIAN TECH UNIV

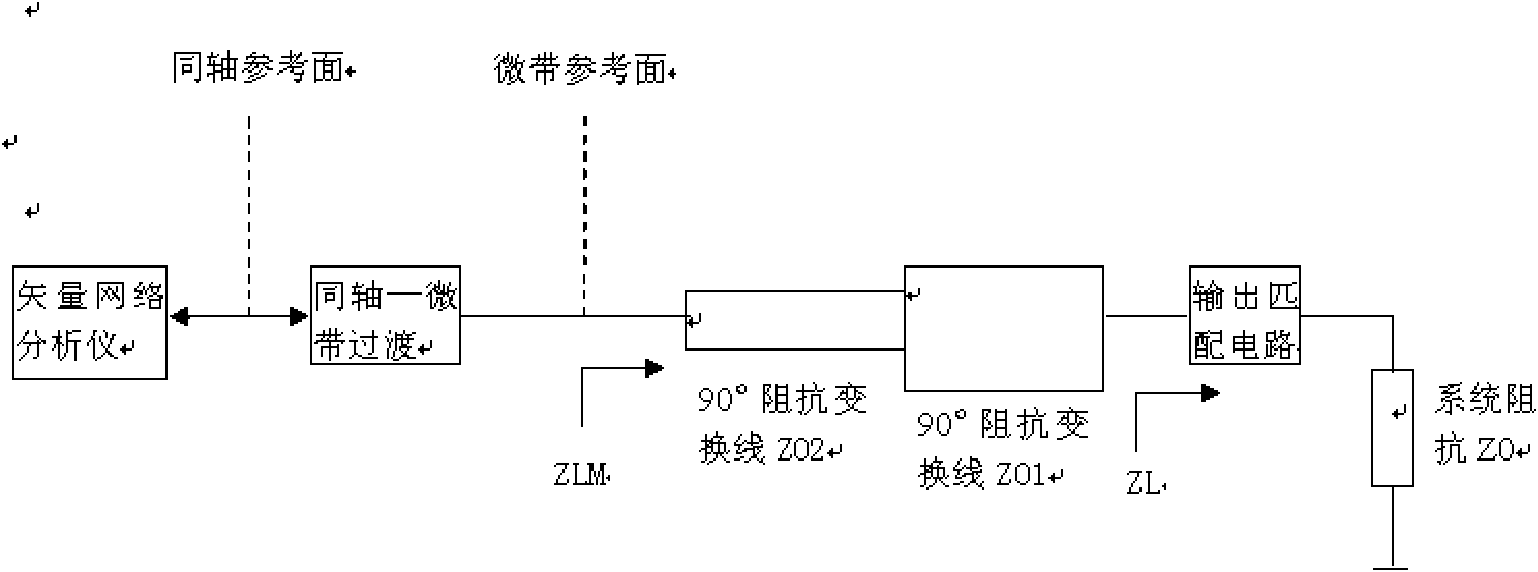

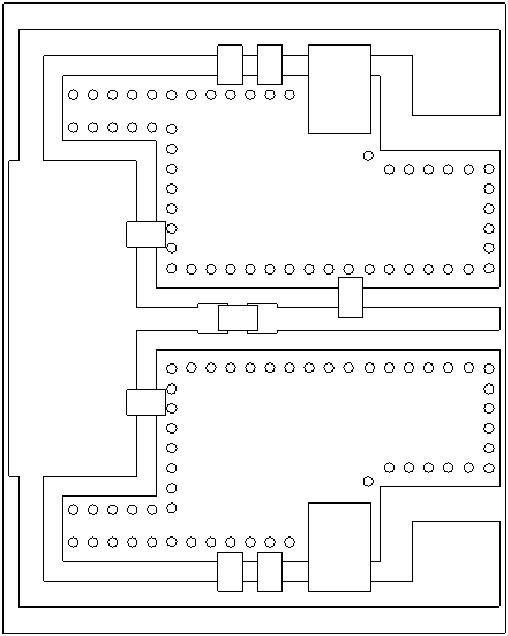

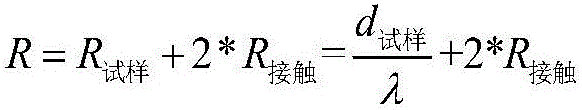

Low radio frequency impedance measuring equipment

ActiveCN101782609AHigh measurement accuracyEliminates the problem of large errors in direct measurement of low RF impedanceResistance/reactance/impedenceMeasurement deviceElectrical impedance

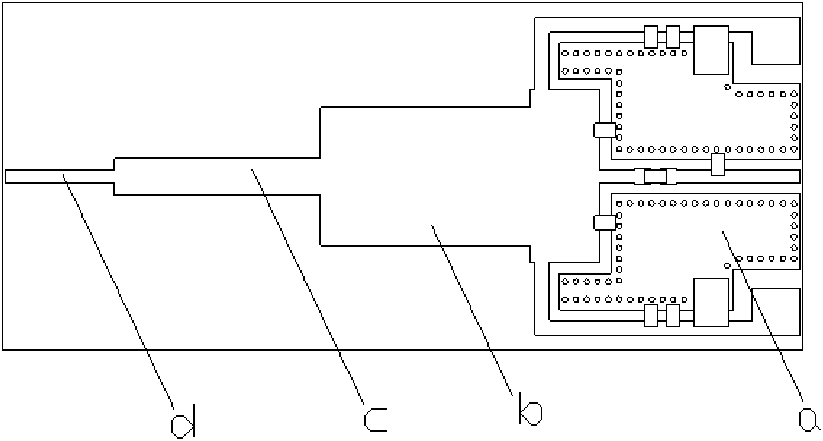

The invention discloses low radio frequency impedance measuring equipment used for assisting radio frequency power amplifier development. The measuring equipment comprises a 50ohm coaxial matched load (1), a coaxial micro-strip transition connector (2), a low radio frequency impedance circuit (3) which is to be measured and additionally provided with two impedance-changing micro strips and a micro strip OSL correction printed circuit board (4); wherein the two impedance-changing micro strips (b and c) improve impedance level of a low radio frequency impedance micro strip circuit (a) to the level which can be accurately measured by a vector network analyzer, thus eliminating big error caused by measuring low radio frequency impedance directly; and a micro strip OSL correcting element eliminates testing error induced by coaxial test port and micro strip circuit transition part, thus measuring accuracy is further improved. The invention has the advantages of simple structure, good measuring accuracy and low cost.

Owner:成都芯通软件有限公司

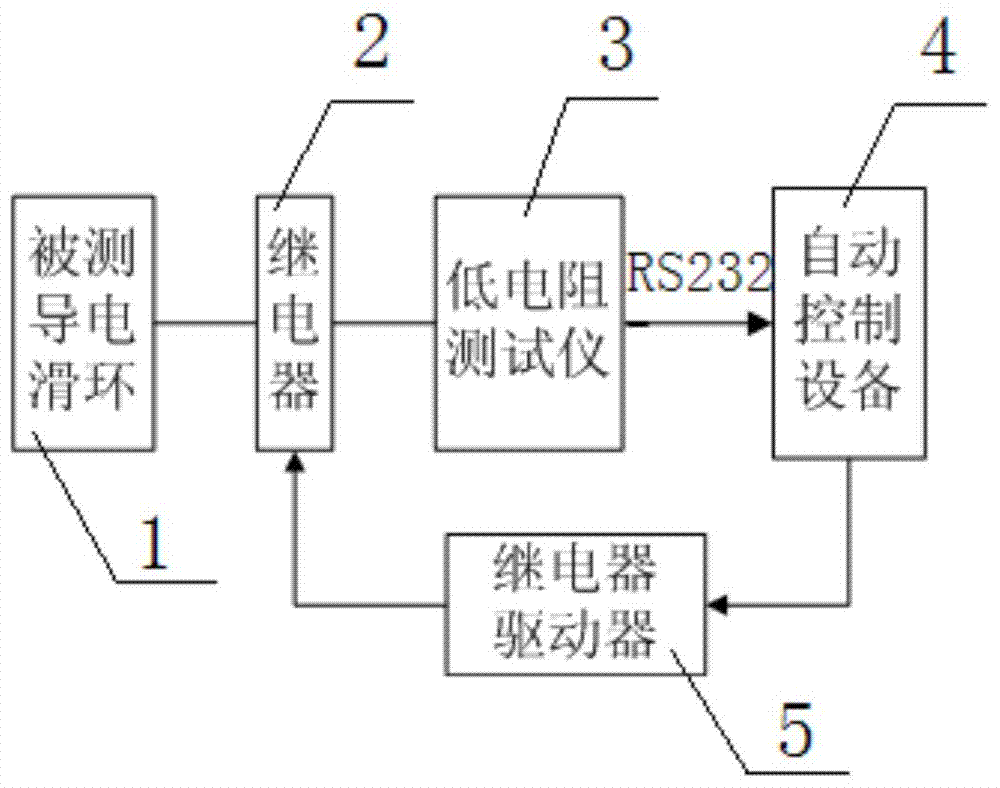

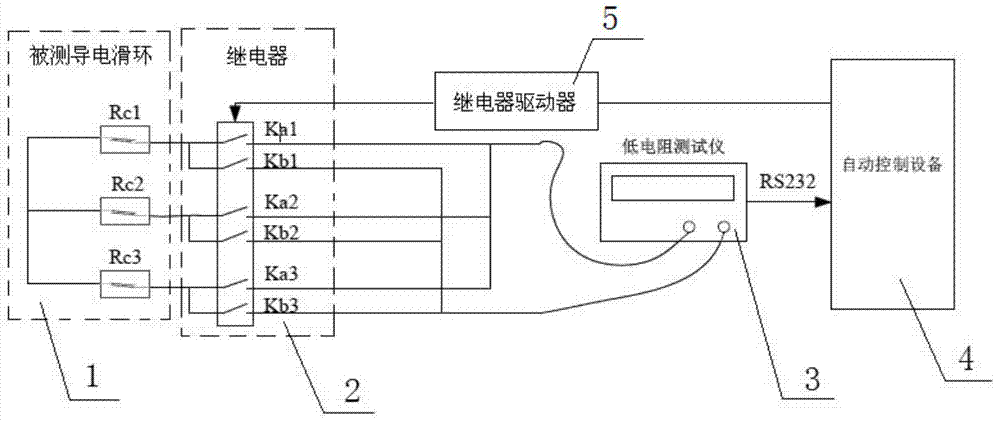

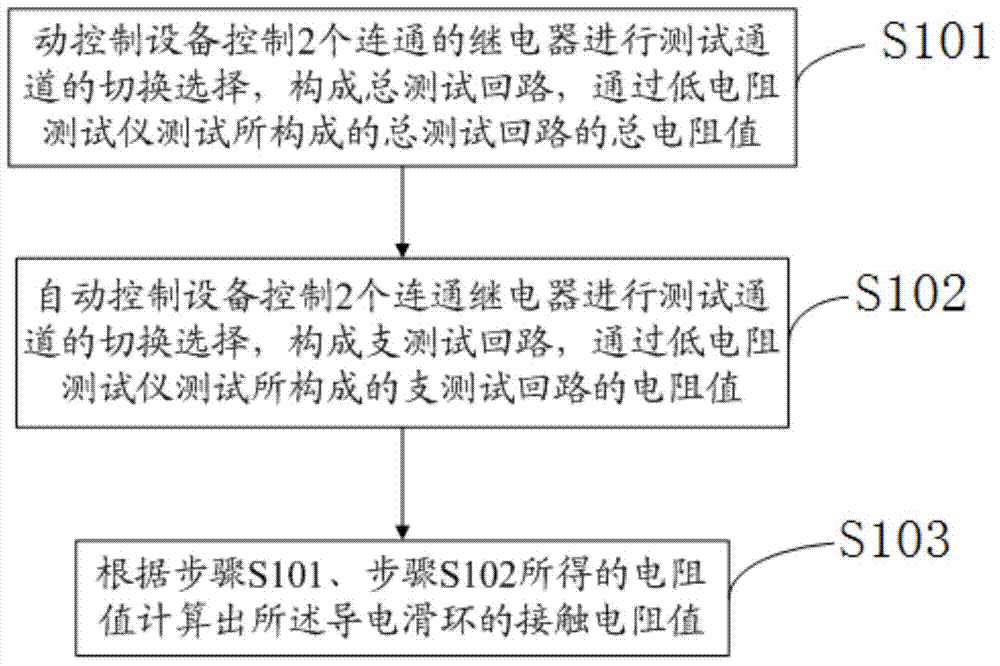

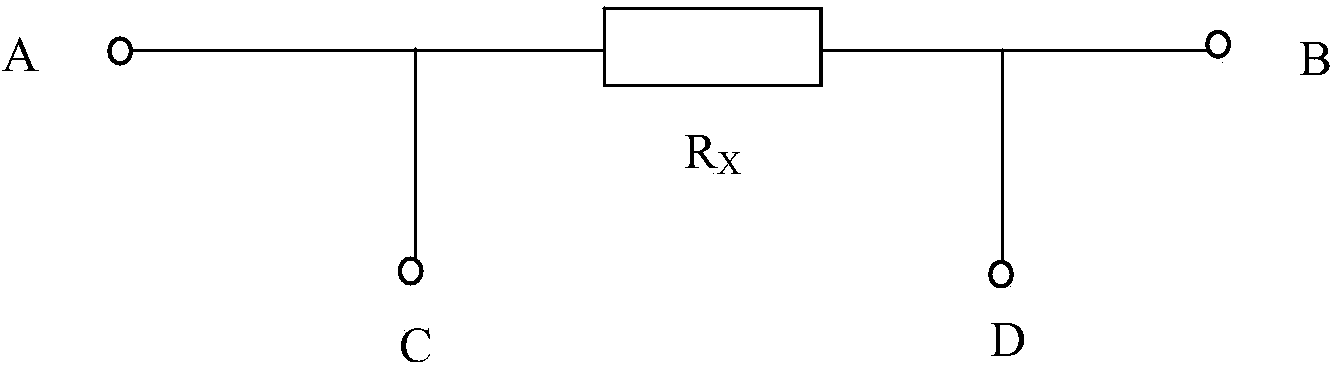

Apparatus and method for testing contact resistance of conductive slip ring automatically

ActiveCN104849559AMeet speed requirementsTest accurateResistance/reactance/impedenceElectrical resistance and conductanceAutomatic control

The invention discloses an apparatus and method for testing contact resistance of a conductive slip ring automatically. A low-resistance tester is arranged outside the apparatus. The apparatus comprises a conductive slip ring, a plurality of relays, a relay drive circuit, an automatic control device, and a plurality of leads. The number N of the relays is twice the number M of channels of the conductive slip ring; the N relays are connected with all M channels of the conductive slip ring to form switching of 2N testing channels; each four adjacent relays complete switching of two four-wire measurement channels. The output terminal of the relay drive circuit is connected with the relays and the input terminal is connected with the automatic control device. According to the invention, with the simple relay switching circuit, rapid testing of contact resistances of multiple paths can be realized; and the individual test error can be eliminated.

Owner:MIANYANG WEIBO ELECTRONICS

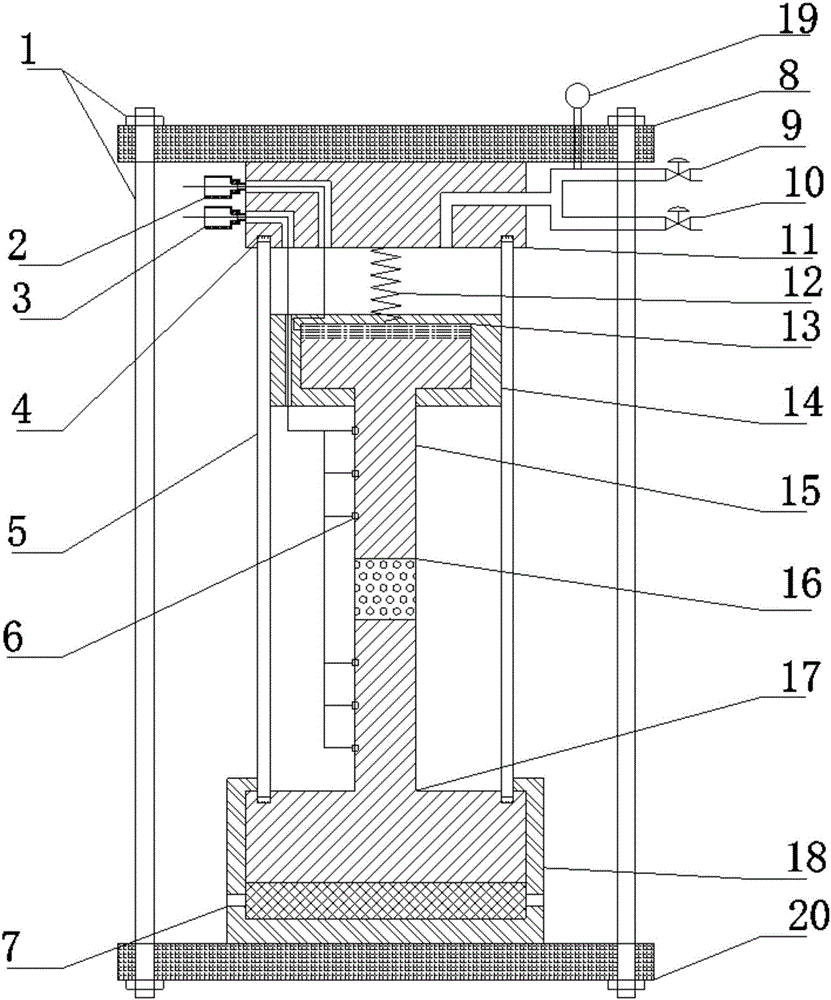

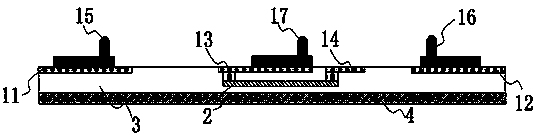

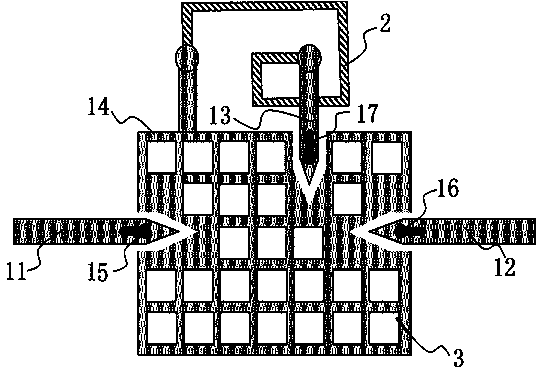

Multifunctional solid material thermophysical property testing device and method

ActiveCN106841297AEliminate test errorsEasy to assemble and disassembleMaterial heat developmentSpecific heat investigationTest sampleContact heat

The invention discloses a multifunctional solid material thermophysical property testing device and method. The device comprises a hot end compression plate and a cold end compression plate connected together through a compression device, wherein the hot end compression plate is in contact with a hot end sealing plate, the hot end sealing plate is connected with a heating plate through an elastic module, and the heating plate is fixed on a hot end base; a seal pipe is arranged between the hot end sealing plate and a cold end base, and the compression device generates a compression force through the hot end compression plate and the cold end compression plate to extrude a seal ring corresponding to the seal pipe so as to form a pressure-bearing seal chamber composed of the hot end sealing plate, the seal pipe and the cold end base; a temperature measuring device and a pressure measuring device are respectively used for measuring temperatures and pressures of a thermophysical property test sample to be tested in the pressure-bearing seal chamber before and after filling or drawing out a gas, and then the thermophysical property of a solid material is tested. The testing device and the testing method provided by the invention can eliminate test errors caused by thermal contact resistance, radiation and heat convection, thereby effectively improving the testing accuracy of thermophysical property parameters.

Owner:SUZHOU RES INST SHANDONG UNIV

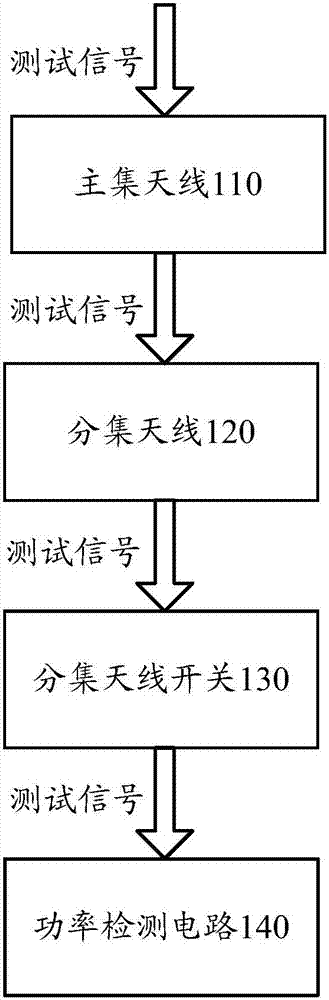

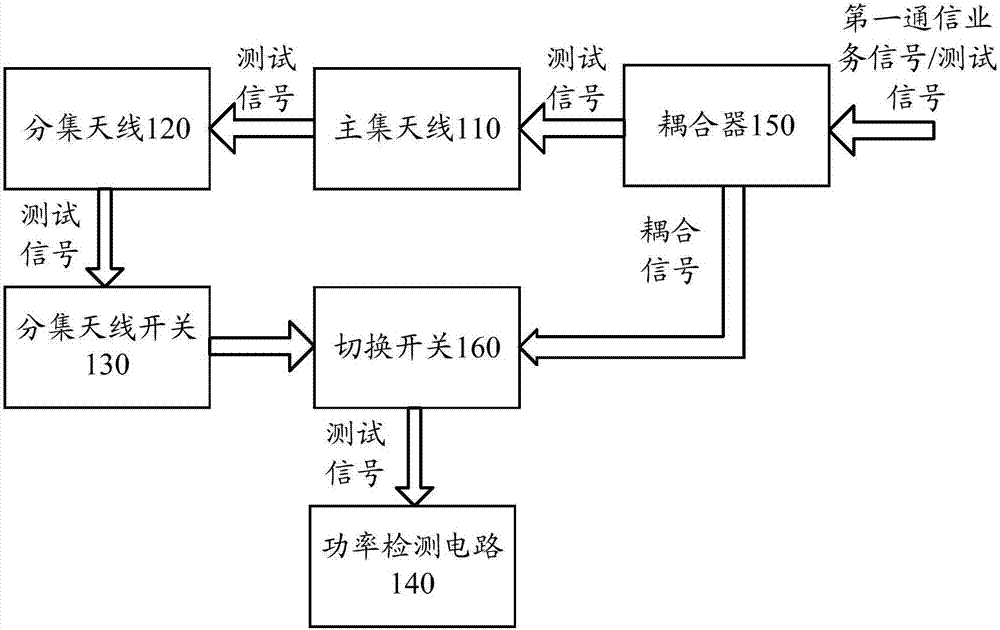

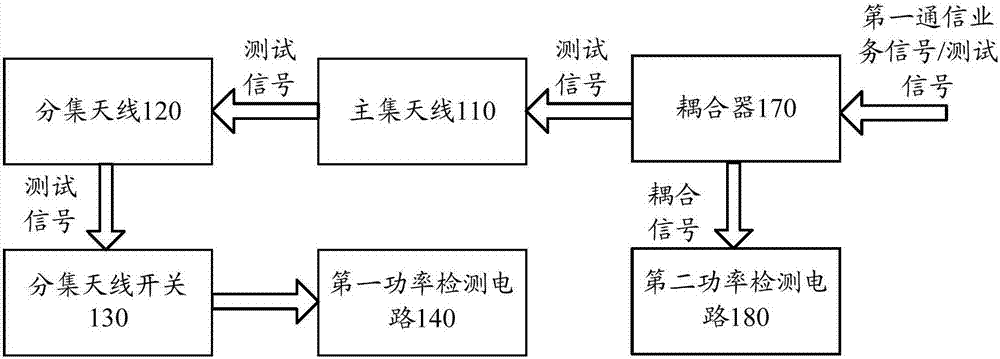

Radio frequency front end circuit of mobile terminal and whole machine coupling testing method

ActiveCN107294557ATo achieve the purpose of coupling testingReduce hardware costsTransmitters monitoringPower managementEngineeringRadio frequency front end

The embodiment of the invention provides a radio frequency front end circuit of a mobile terminal and a whole machine coupling testing method. The radio frequency front end circuit comprises a master antenna, a diversity antenna, a diversity antenna switch and a first power detection circuit, wherein the diversity antenna uses coupling effects between the master antenna and the diversity antenna and receives testing signals transmitted by the master antenna; the input end of the diversity antenna switch is connected with the diversity antenna for receiving the testing signals from the diversity antenna; the output end of the diversity antenna switch is used for outputting the testing signals to the first power detection circuit; and the first power detection circuit is used for carrying out power detection on the testing signals to realize whole machine coupling test on the mobile terminal. Thus, dependence on an integrated test instrument can be eliminated, and the hardware cost in the case of whole machine coupling test is reduced.

Owner:HONOR DEVICE CO LTD

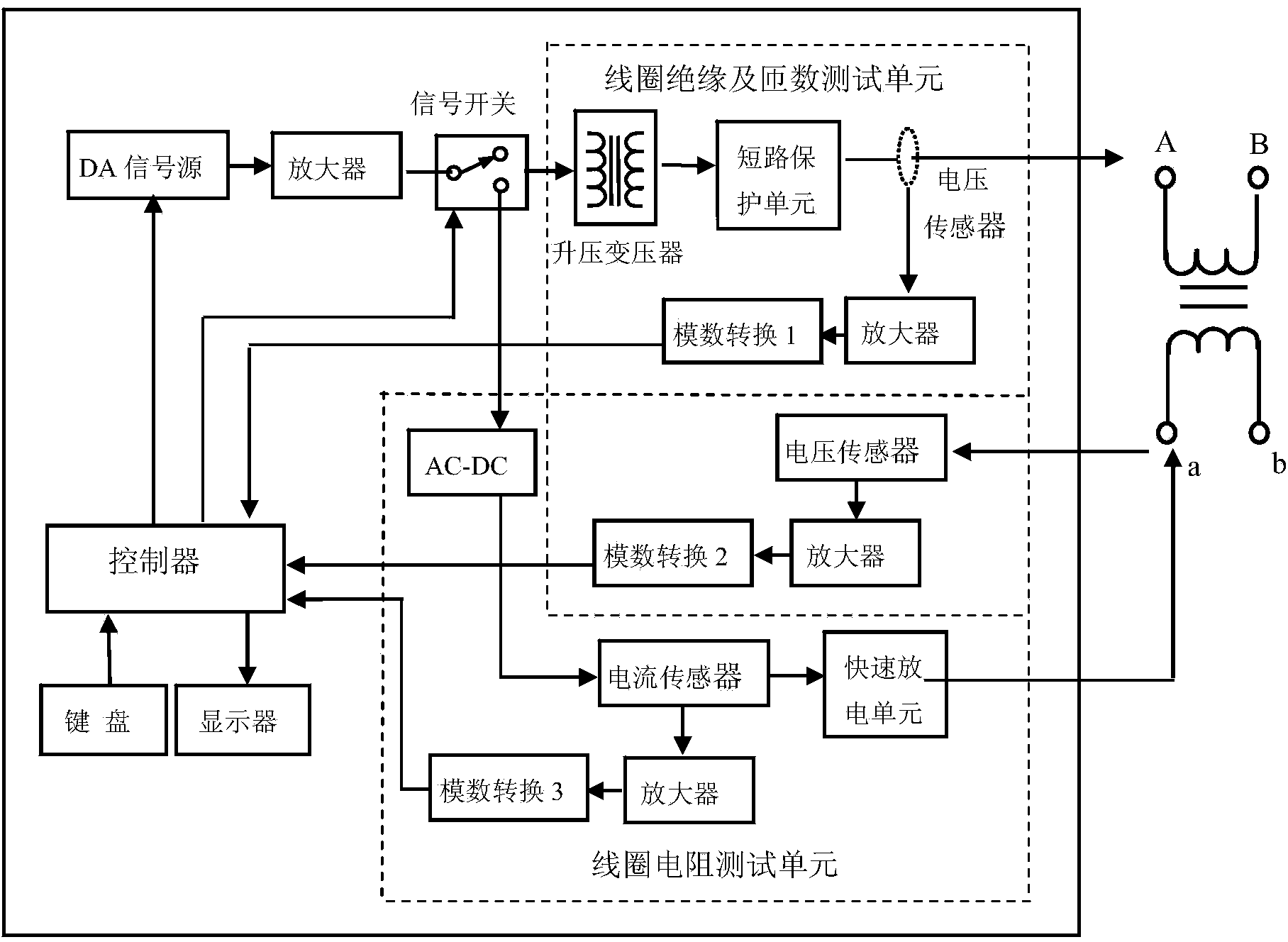

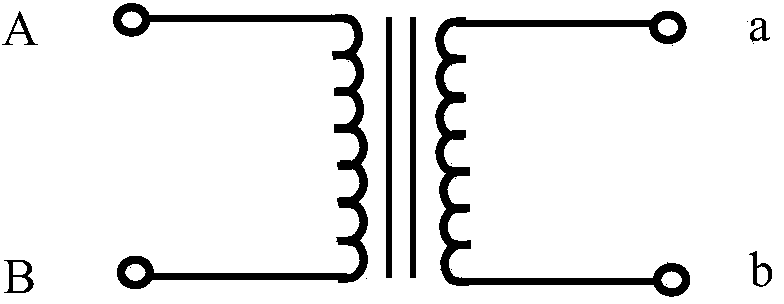

Device for testing characteristics of breaker opening and closing coils

ActiveCN103454580AImprove accuracy and anti-interference abilityEliminate test errorsTesting dielectric strengthCircuit interrupters testingEngineeringPull off test

The invention discloses a device for testing the characteristics of breaker opening and closing coils. The device comprises a controller, a coil resistance testing unit and a coil insulation and number-of-turns testing unit. The controller is respectively connected with a signal source, the coil resistance testing unit and the coil insulation and number-of-turns testing unit, the coil resistance testing unit and the coil insulation and number-of-turns testing unit perform testing through a coil to be tested, tested data are sent to the controller, the controller performs fault diagnosis on the breaker opening and closing coils in real time, and therefore real-time monitoring of the breaker opening and closing coils is realized. According to the device, the performance and the quality of the coils are estimated through testing of the characteristics of the coils, quality defects and fault hidden dangers are eliminated, the reliability and the stability of products in use are guaranteed, and the operation safety of a power system is improved.

Owner:STATE GRID CORP OF CHINA +1

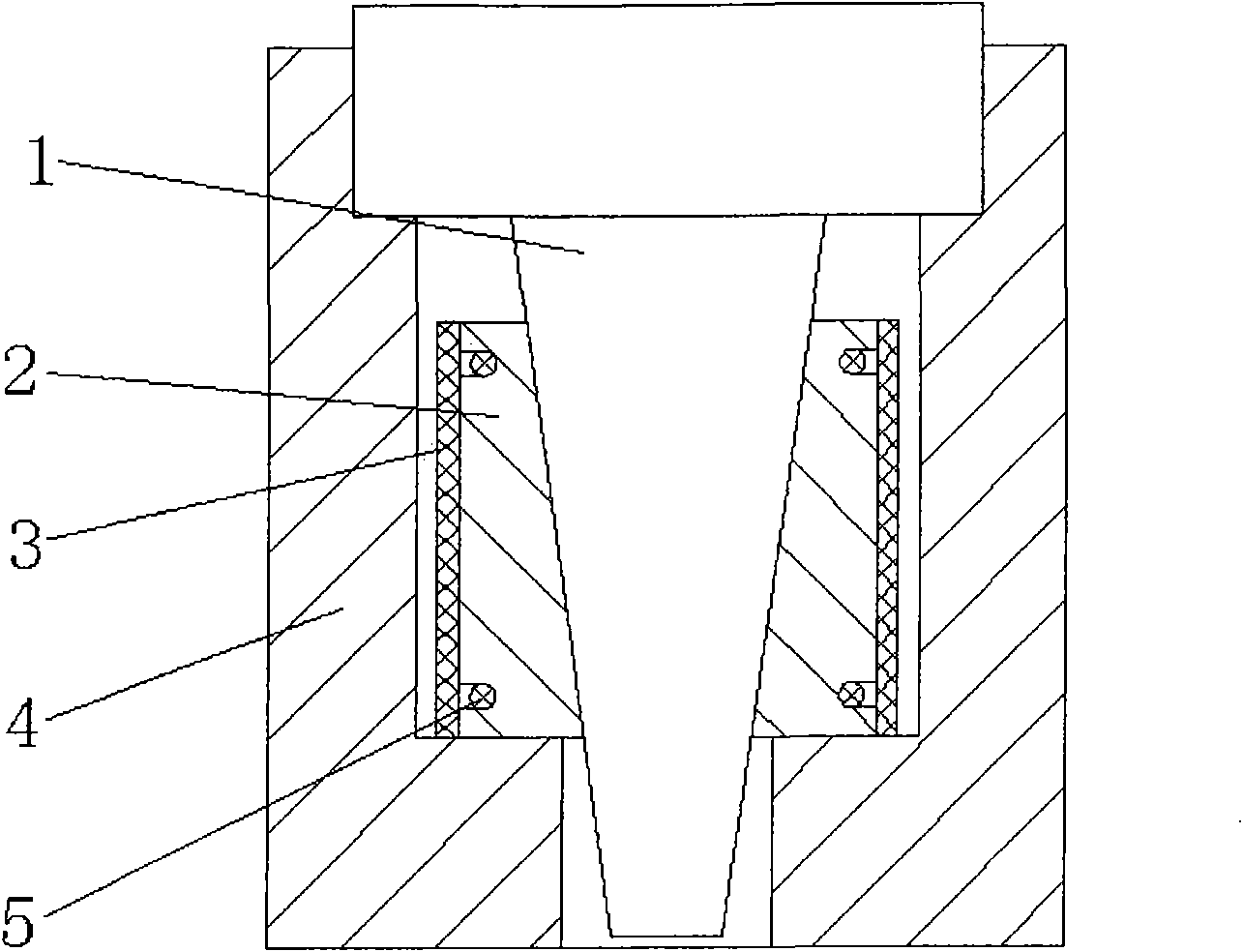

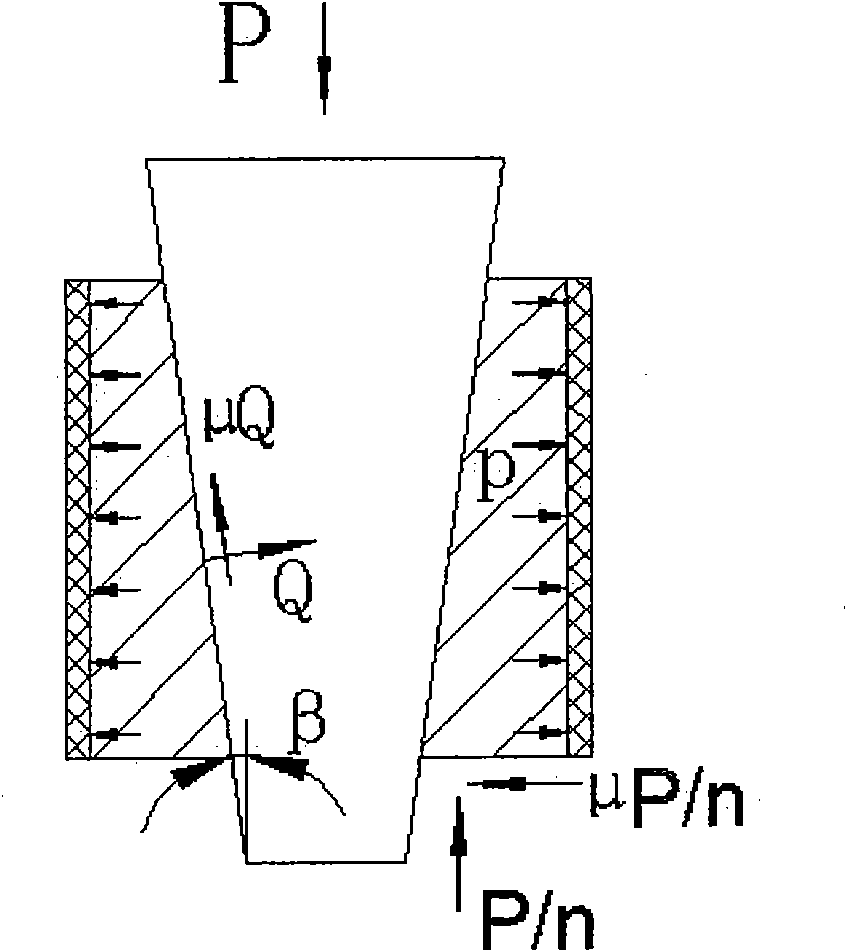

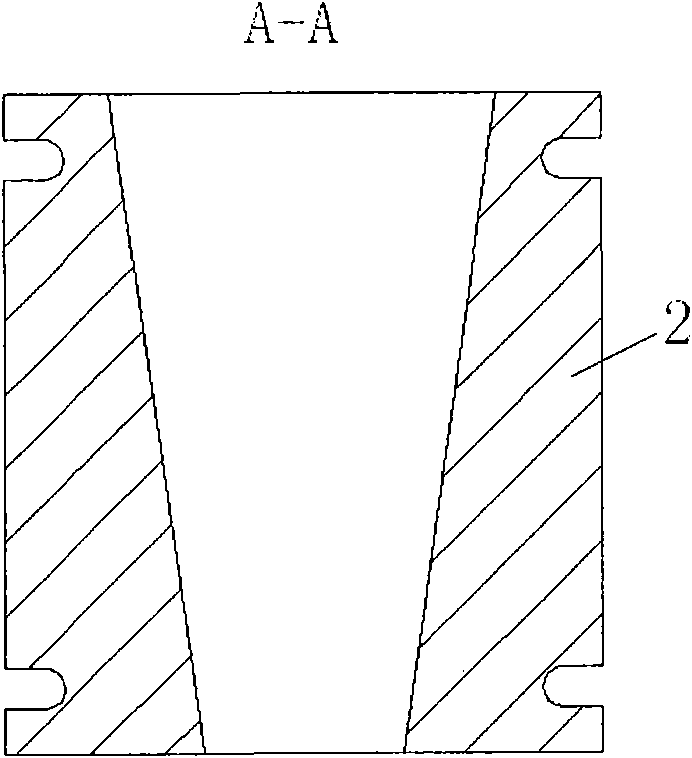

Circumferential mechanical property testing device of valve-model type thin-wall tube

InactiveCN101793646ARealize the test of circumferential mechanical propertiesAchieve bulgingMaterial strength using tensile/compressive forcesAxial pressureStrength of materials

The invention relates to a circumferential mechanical property testing device of a valve-model type thin-wall tube, comprising a cone-shaped pressure head, a value model and a protecting sleeve, wherein the valve model is positioned in a measured test tube, the cone-shaped pressure head is positioned in the value model, the cone-shaped pressure head and the value model are placed into the protecting sleeve together, the maximal inner diameter of the protecting sleeve is in clearance fit with the outer diameter of a platform of the cone-shaped pressure head, a half-cone angle of the extrusion work end taper of the cone-shaped pressure head is 8 degrees or 10 degrees or 12 degrees or 15 degrees, the valve model comprises a plurality of values with the same shape and structures, the aperture of one end of an inner hole of the protecting sleeve is equal to the outer diameter of the fitting platform of the cone-shaped pressure head, the aperture of the middle part of the protecting sleeve is larger than the outer diameter of the measured test tube, the aperture of the other end of the protecting sleeve is larger than the outer diameter of the cone-shaped end of the fitted cone-shaped pressure head, and after the cone-shaped end of the cone-shaped pressure head is not interfered with the protecting sleeve after being arranged in the inner hole. In a loaded process on a material mechanical property testing machine, the axial pressure is converted into radial bulging force, and the real circumferential mechanical property of the thin-wall tube is accurately obtained, thereby providing accurate mechanical property support for subsequent design and engineering application of the thin-wall tube.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

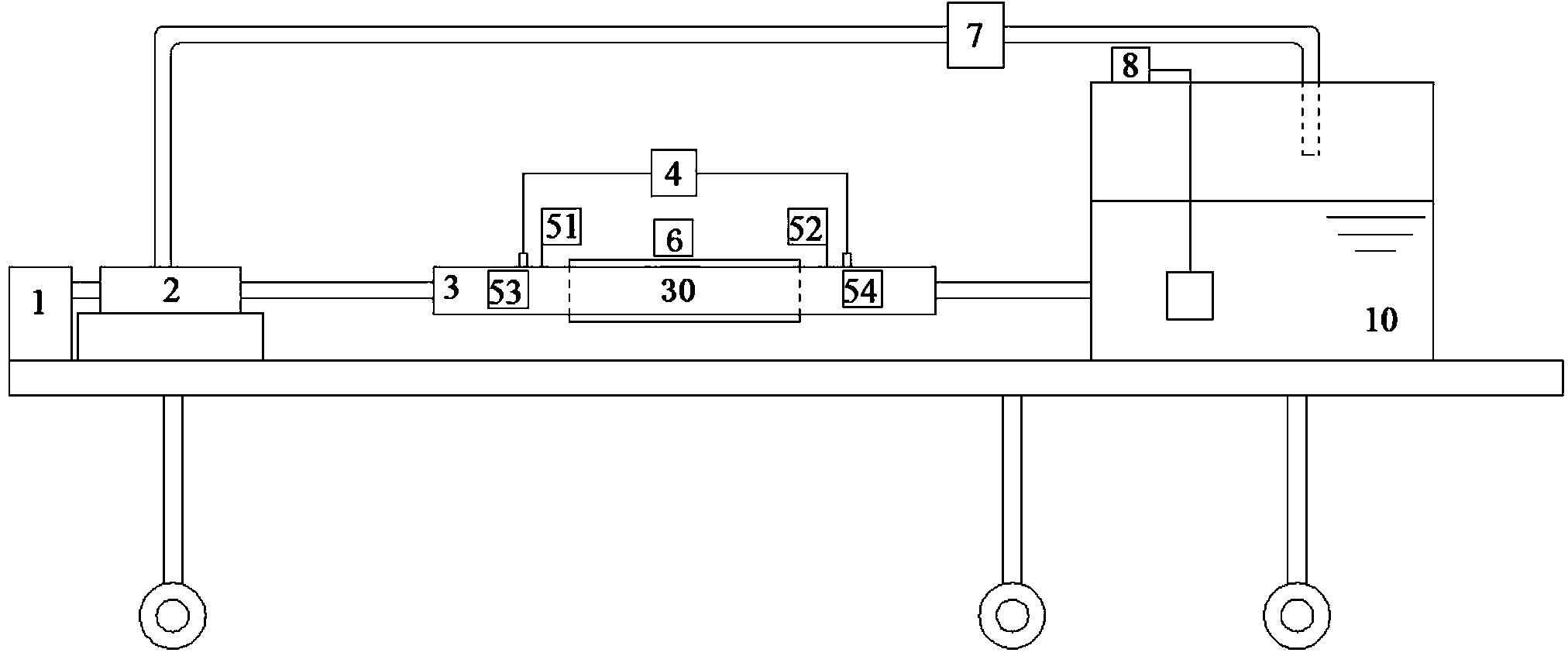

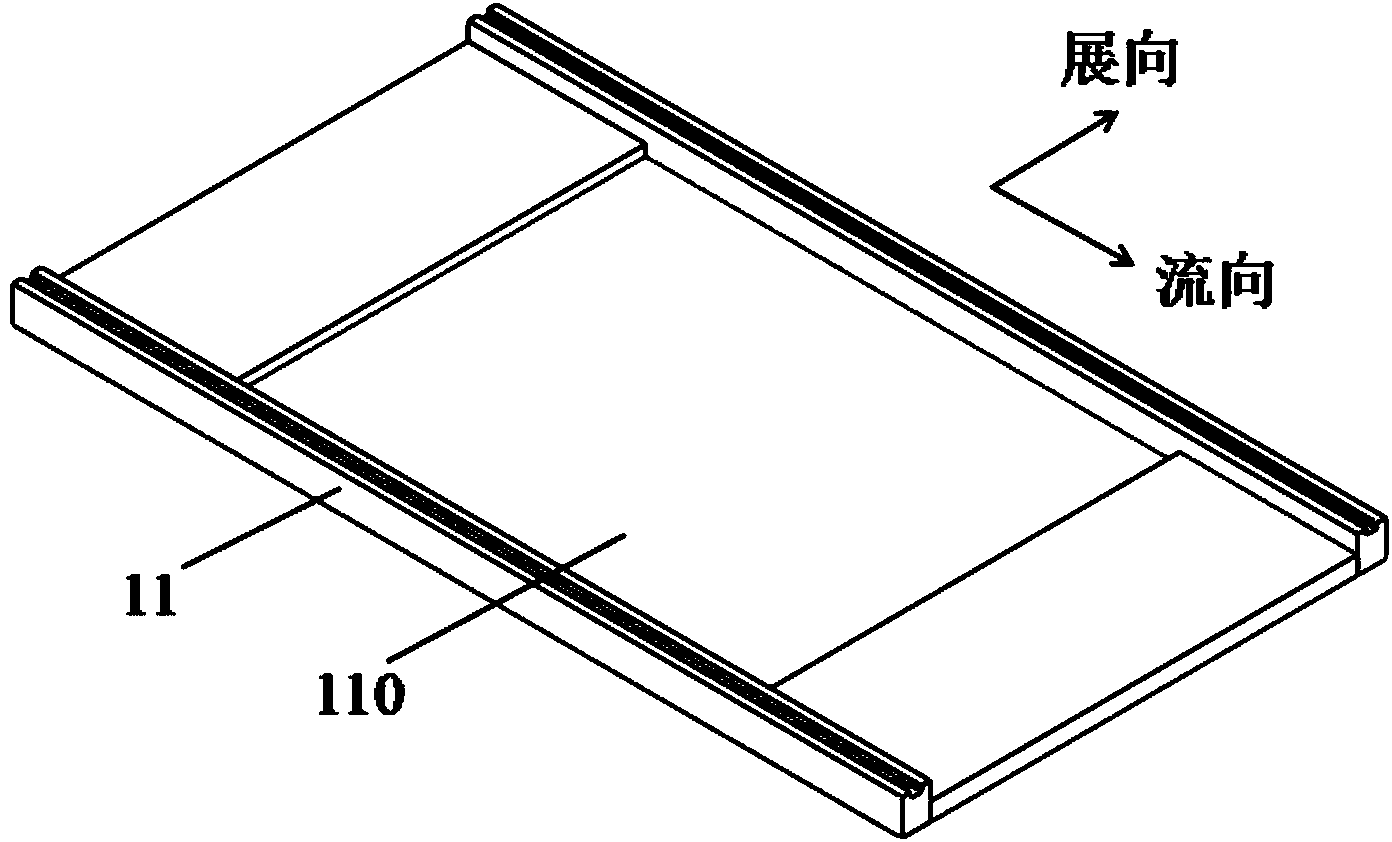

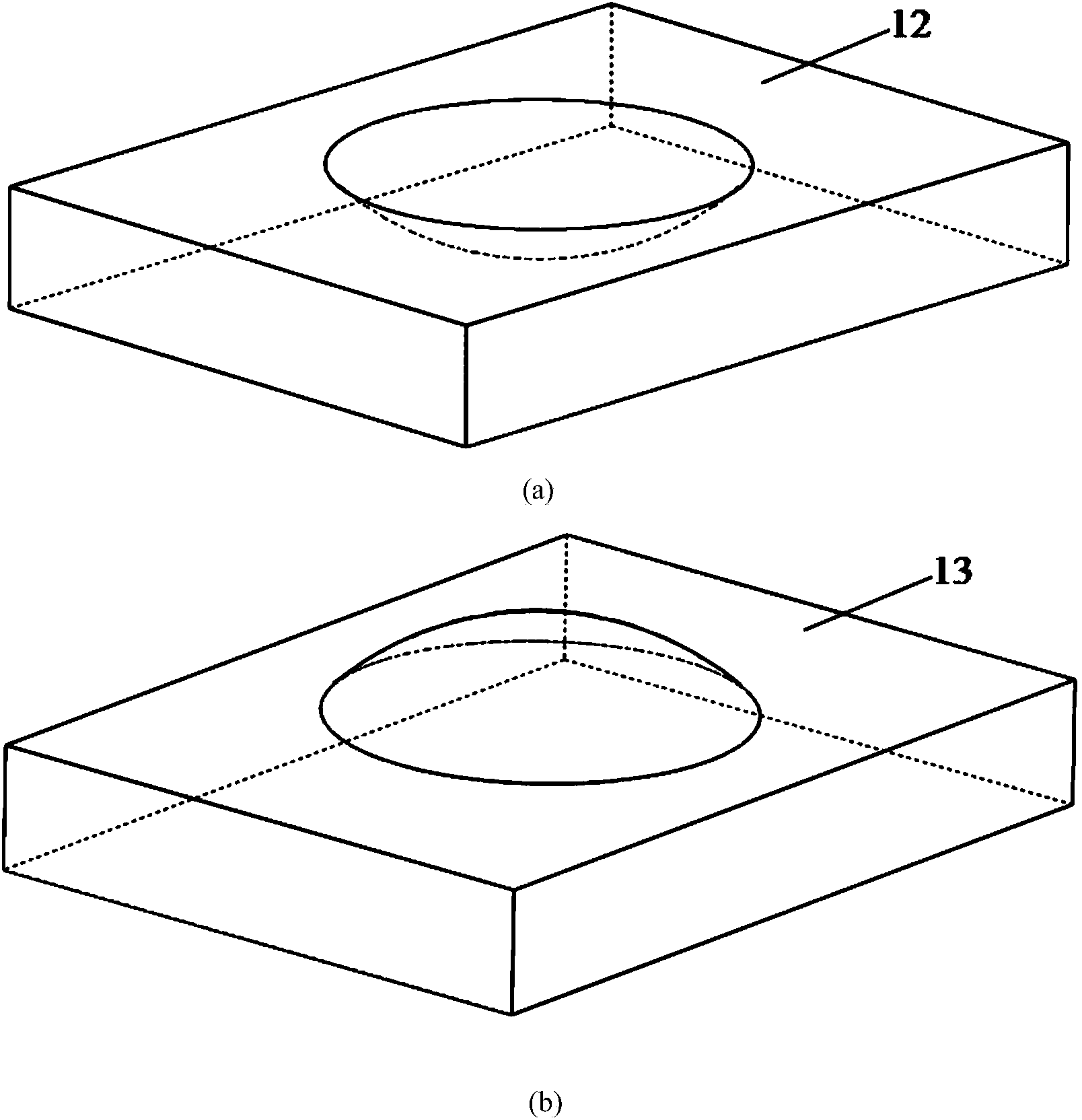

Fluid flow heat-exchanging experimental device with ball socket/ball bulge flow control structure

ActiveCN103616404AChange relative depthChange spanwise spacingMaterial heat developmentTemperature controlEngineering

The invention discloses a fluid flow heat-exchanging experimental device with a ball socket / ball bulge flow control structure. The fluid flow heat-exchanging experimental device comprises a speed adjusting motor, a centrifugal pump, a testing section, an electric heating system, a flow meter, a water tank temperature control system and a water tank, wherein the speed adjusting motor is connected with the centrifugal pump; a water outlet of the water tank is communicated with an inlet of the testing section and an outlet of the testing section is communicated with the inlet of the centrifugal pump; the outlet of the centrifugal pump is communicated with the water tank; the testing section comprises an experimental channel upper cover plate and an experimental channel lower cover plate which are buckled with each other; a concave region is arranged in the middle of the experimental channel lower cover plate; the concave region is internally filled with a building block type ball socket / ball bulge flow control structure. According to the fluid flow heat-exchanging experimental device, a relative depth, a spanwise spacing and a streamwise spacing of a ball socket / ball bulge in a channel and the manner of combining the ball socket with the ball bulge are changed by replacing the ball socket / ball bulge, a spanwise filling block, a streamwise filling block and the like; a whole molding design method of the testing channel is improved by the design; building block type blocked structural design is adopted and the change of geometrical parameters of the channel can be finished conveniently and rapidly in a time-saving and labor-saving manner.

Owner:XI AN JIAOTONG UNIV

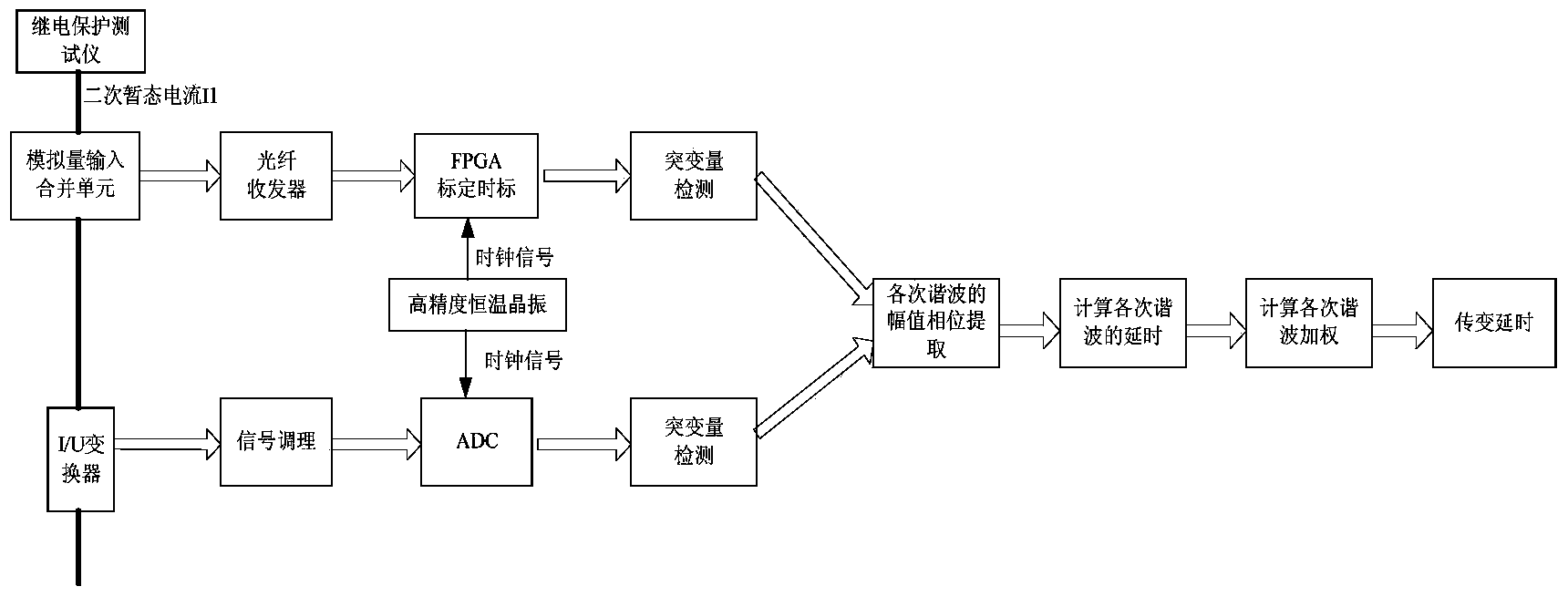

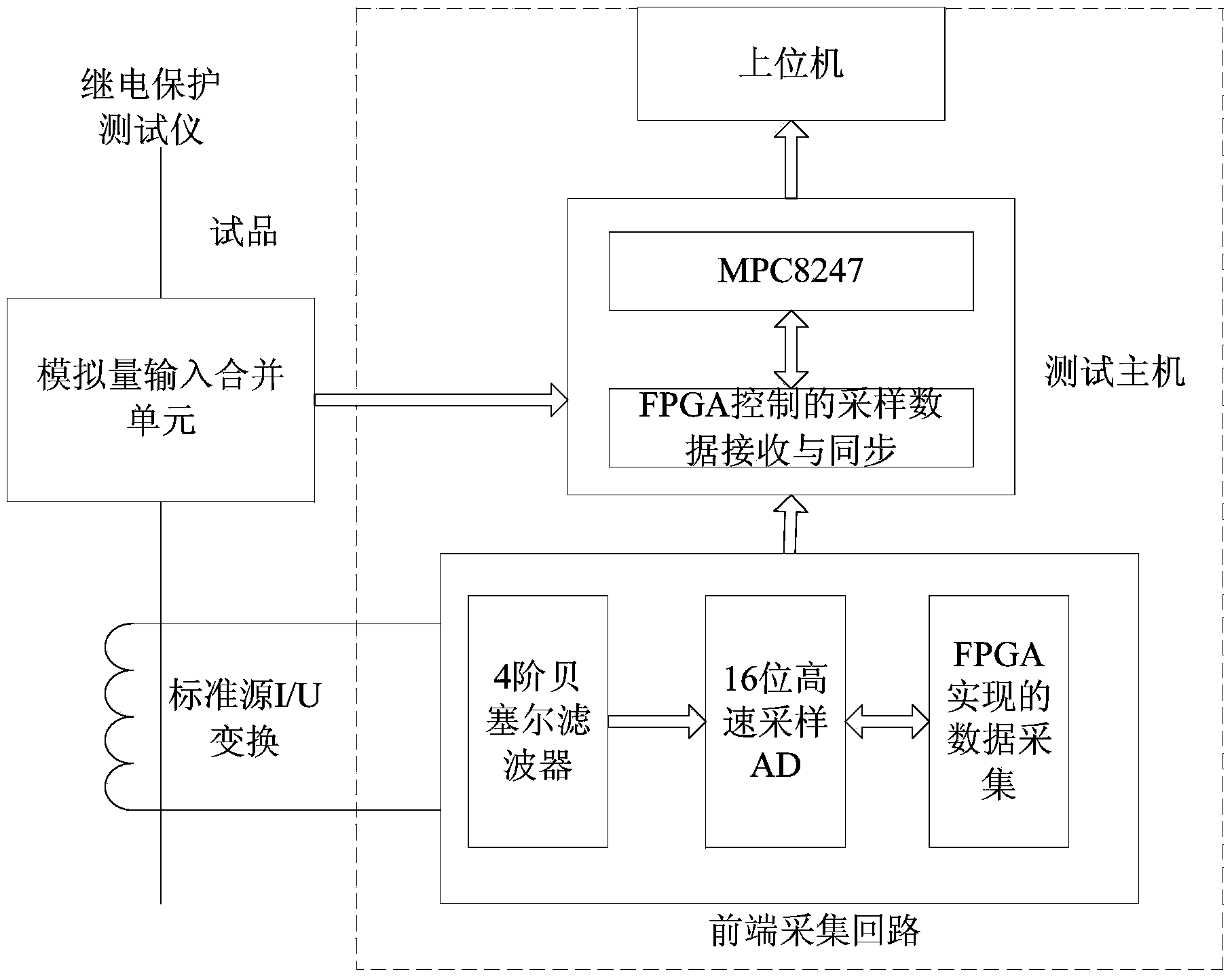

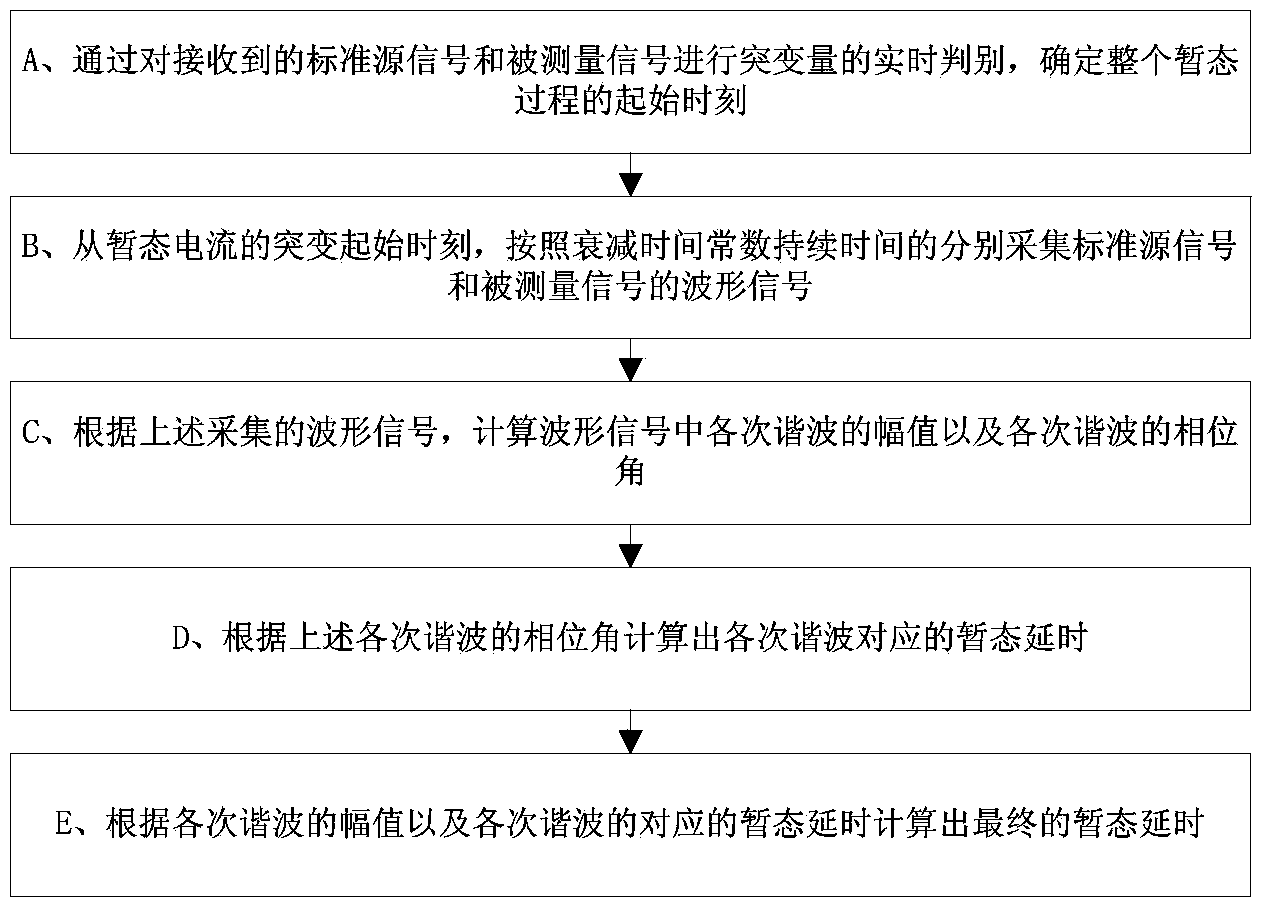

Analog quantity merging unit transient state delay test method based on frequency scanning

ActiveCN104007346AImprove sampling accuracyImprove general performanceElectrical testingTransient stateLow-pass filter

The invention discloses an analog quantity merging unit transient state delay test method based on frequency scanning. Sudden-change quantities of a received standard source signal and a signal to be measured are judged in real time, a starting moment of a transient state process is determined, waveform signals are collected, the amplitude and the phase angle of each harmonic are calculated, the transient state delay corresponding to each harmonic is calculated, and ultimately, the ultimate transient state delay is calculated according to the amplitude of each harmonic and the transient state delay corresponding to each harmonic. Transient state transmission time is calculated through a weighting coefficient, test currents do not need to be output specially, universality is high, and the method is suitable for all merging units with low-pass filter coefficients, port modes and port protocols currently. A high-precision constant-temperature crystal oscillator is used for controlling timing sequence and eliminating errors, the transient state starting moment of tested data is guaranteed, and sampling precision of higher harmonics is improved by means of a four-step Bessel filter. The analog quantity merging unit transient state delay test method based on frequency scanning can be widely used in the field of relay protection and verification.

Owner:ELECTRIC POWER RES INST OF GUANGXI POWER GRID CO LTD +2

Panel performance testing system

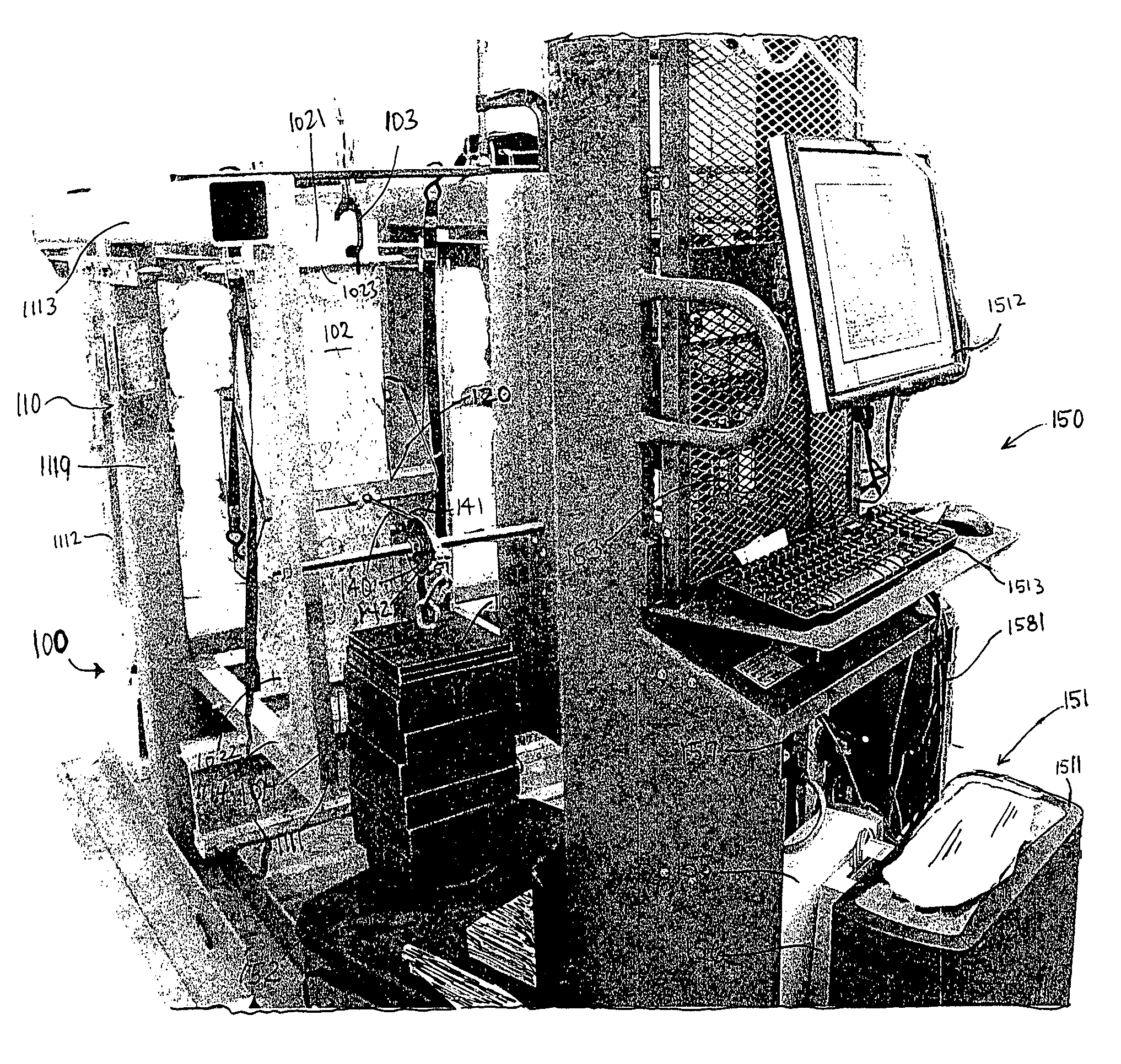

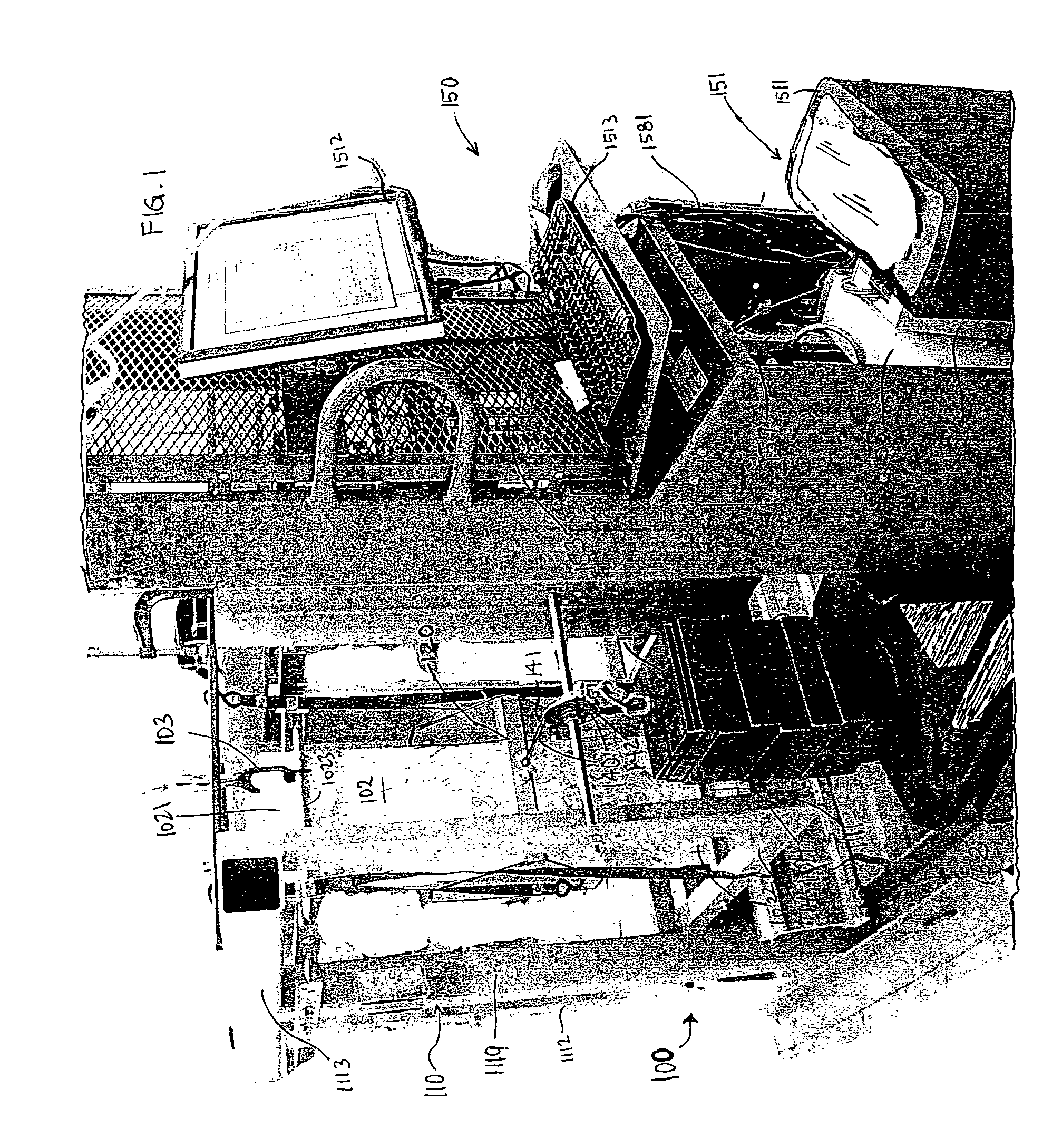

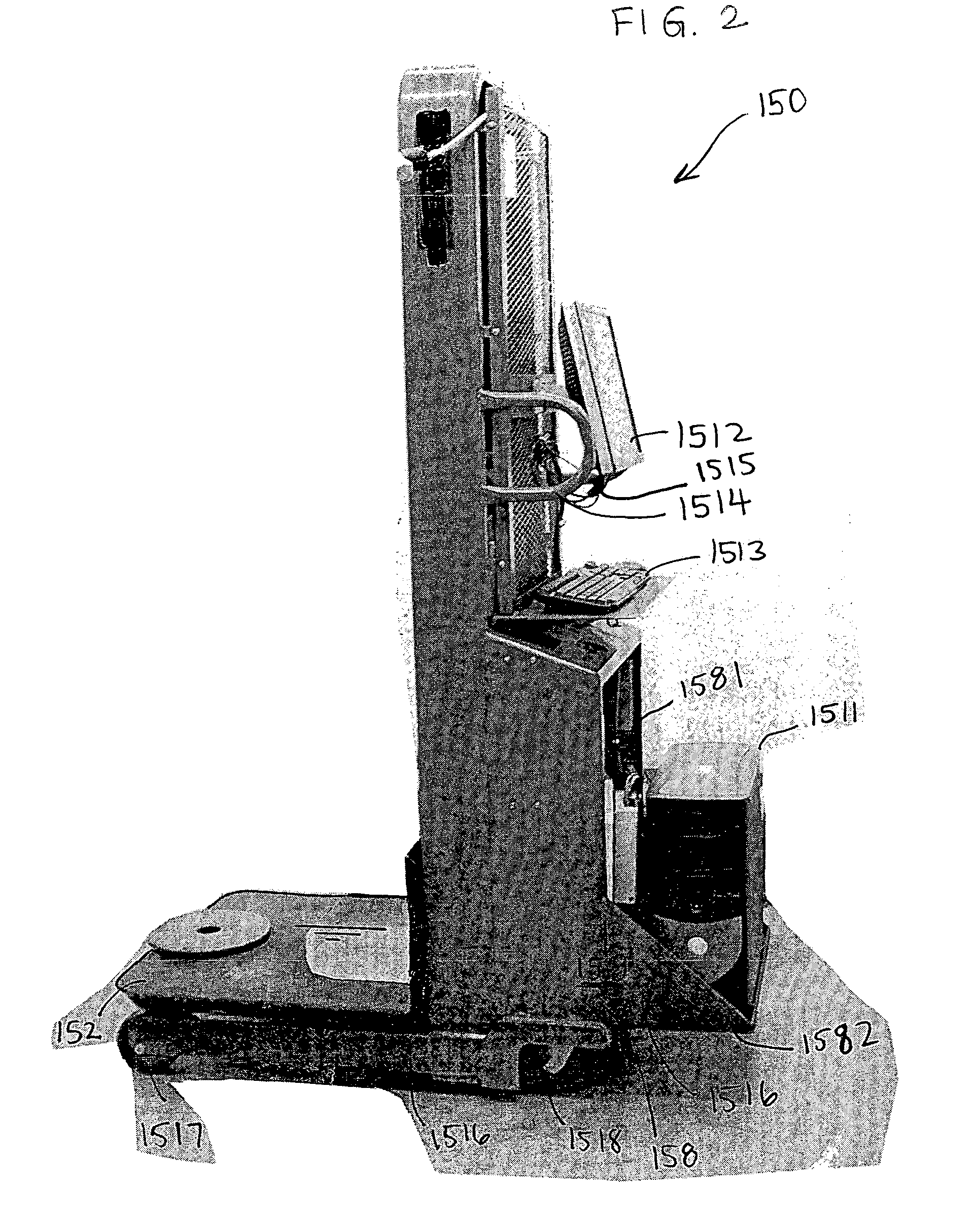

InactiveUS7089803B1Improve test efficiencyReduce equipment costsMaterial strength using steady bending forcesData acquisitionEngineering

A panel performance testing system and method of use is provided for evaluating creep and duration of load (DOL) performance of products, particularly wood-based panels, subjected to bending stress. The panel performance testing system comprises a panel testing support frame assembly; a loading head assembly for applying test load to a panel face; a load transfer assembly for transferring load force from a dead weight to the loading head assembly; a panel deflection sensor; and a mobile loading platform assembly for vertically positioning and supporting dead weight loads, controlling the rate of load transfer of the dead weight loads from the loading platform assembly to the loading head assembly, and an integrated data acquisition system that automatically records and processes the related testing data for the entire course of the testing.

Owner:HUBER ENGINEERED WOODS

Environment friendly anti-corrosive paint and preparation thereof

InactiveCN101497755AIncreased corrosion potentialCorrosion current reductionAnti-corrosive paintsEpoxy resin coatingsAmmonium sulfateMagnesium

The invention discloses environmental-friendly anti-corrosive polyaniline paint which has high content of polyaniline, good anti-corrosion performance and low cost, causes no pollution and is suitable for preventing steel, magnesium and other metals from being corroded. The environmental-friendly anti-corrosive polyaniline paint contains component A and component B which have the weight ratio of 7:1 to 17:1, wherein the component A contains the following components according to the portion by weight: 40-80 portions of liquid epoxy resin, 4-40 portions of plasticizing agent, 0.1-4 portion(s) of emulsifying agent OP-10, 4-10 portions of small-molecular fatty alcohol, 0.1-15 portion(s) of ammonium persulfate, 0.1-3 portion(s) of distilled water, 0.1-2 portion(s) of 0.4-0.8mol / L camphorsulfonic acid solution, 0.1-16 portion(s) aniline, 0.5-1 portion of defoaming agent and 4-20 portions of reactive diluent.

Owner:SHANDONG UNIV

Method for monitoring damage of concrete structure based on piezoelectric intelligent aggregate

InactiveCN108896389AEliminate test errorsSolving Uncertainty ProblemsMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesRecognition algorithmElectricity

The invention discloses a method for monitoring the damage of a concrete structure based on piezoelectric intelligent aggregate. The method comprises the following steps: designing a piezoelectric intelligent aggregate sensor and a driver which are independently packaged; and establishing a damage statistical index of the concrete structure based on wavelet analysis and a method for determining the damage degree, the damage probability and the damage position, and providing a statistical recognition algorithm for the damage of the concrete structure of the piezoelectric intelligent aggregate based on wavelet analysis. According to the method disclosed by the invention, the influences of partial test errors are eliminated to a certain degree, and the uncertainty of a damage identification problem is well reflected and is converted into mathematical description in the probability statistical significance, so that the problem of uncertainty of the damage identification is effectively solved, the damage degree and damage probability of the concrete structure can be determined, and the rough position (range) of the damage can be effectively recognized.

Owner:BEIHUA UNIV

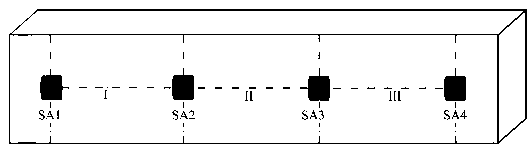

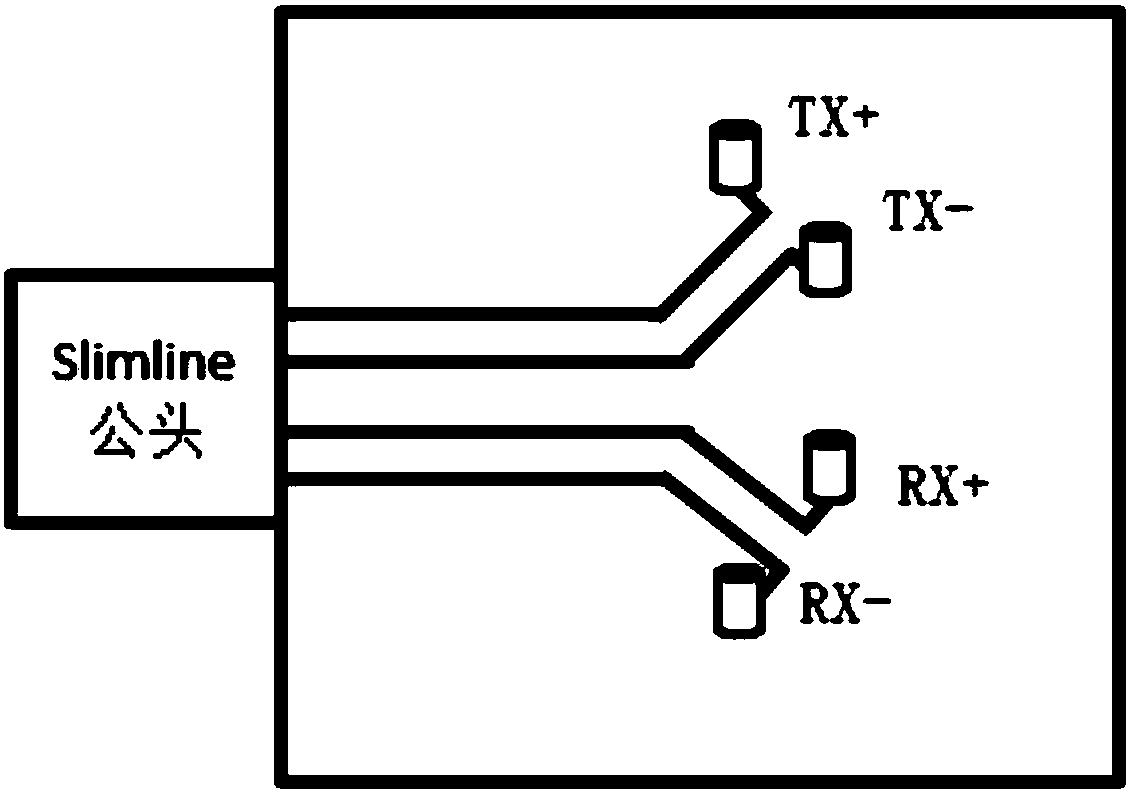

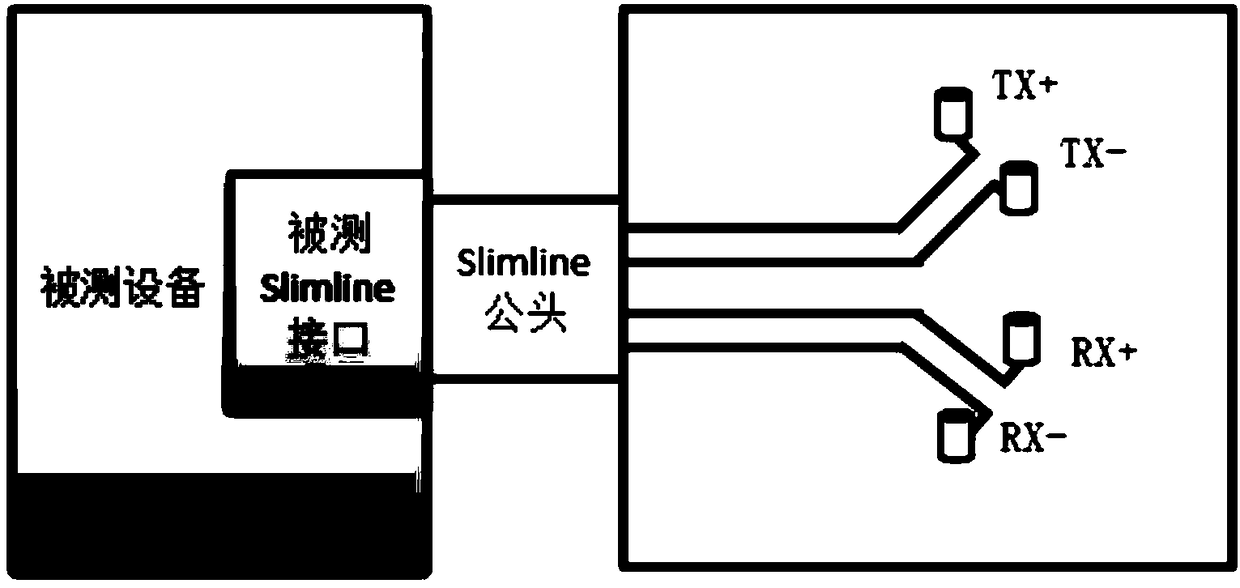

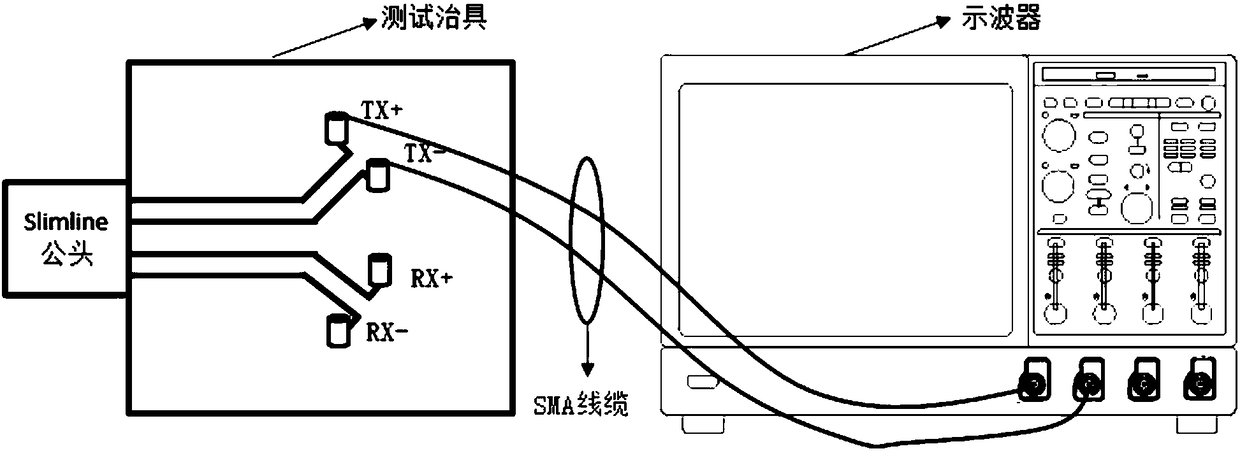

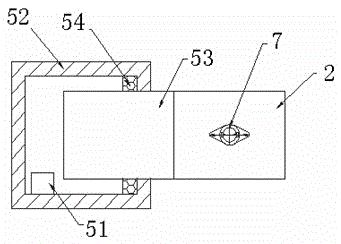

Slimline interface SATA signal test fixture and test method

InactiveCN108107237AEasy to testEasy to operateElectric connection testingMeasurement instrument housingTest efficiencyEngineering

The invention provides a Slimline interface SATA signal test fixture and test method. The test fixture is composed of a Slimline male head, two pairs of PCB wires and two pairs of SMA male heads. TheSlimline male head connects the test fixture and the tested interface. The PCB wires lead the signal to the SMA male head interface from the Slimline interface. The SMA male head is connected with anoscilloscope through an SMA cable. According to the test fixture, the Slimline interface SATA signal test can be conveniently performed and connection with the oscilloscope through the SMA cable can be realized so that operation is flexible and convenient, the test efficiency can be enhanced, the measurement error caused by direct spot measurement through the probe can be eliminated and the test accuracy can be enhanced.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

Automatic optical gate device of spectrophotometer

InactiveCN101592596AReduce operating errorsSimple and fast operationColor/spectral properties measurementsGratingLight beam

The invention relates to an improved component structure of a spectrophotometer as a scientific analysis experimental instrument, in particular to a verifying mechanism which is used for automatically regulating 0 percent Tau and 100 percent Tau before the spectrophotometer is used. An automatic optical gate device of the spectrophotometer comprises a receiving darkroom (4) positioned beside a sample chamber (7), a biconvex lens (6) and a photoelectric receiver (4) are sequentially arranged in the receiving darkroom (4) on the light incident direction of an optical gating, a permanent magnet (13) which can move up and down is arranged between the biconvex lens (6) and the photoelectric receiver (4), an electromagnetic coil (12) is arranged above the permanent magnet (13), the lower part of the permanent magnet (13) is connected with an optical gate (15), and a positioning seat (16) is arranged below the optical gate (15). The invention has convenient use, fast operation, high automation degree and strong accuracy, thereby being a spectrophotometer automatic power-on verifying mechanism which has practical value.

Owner:上海现科分光仪器有限公司

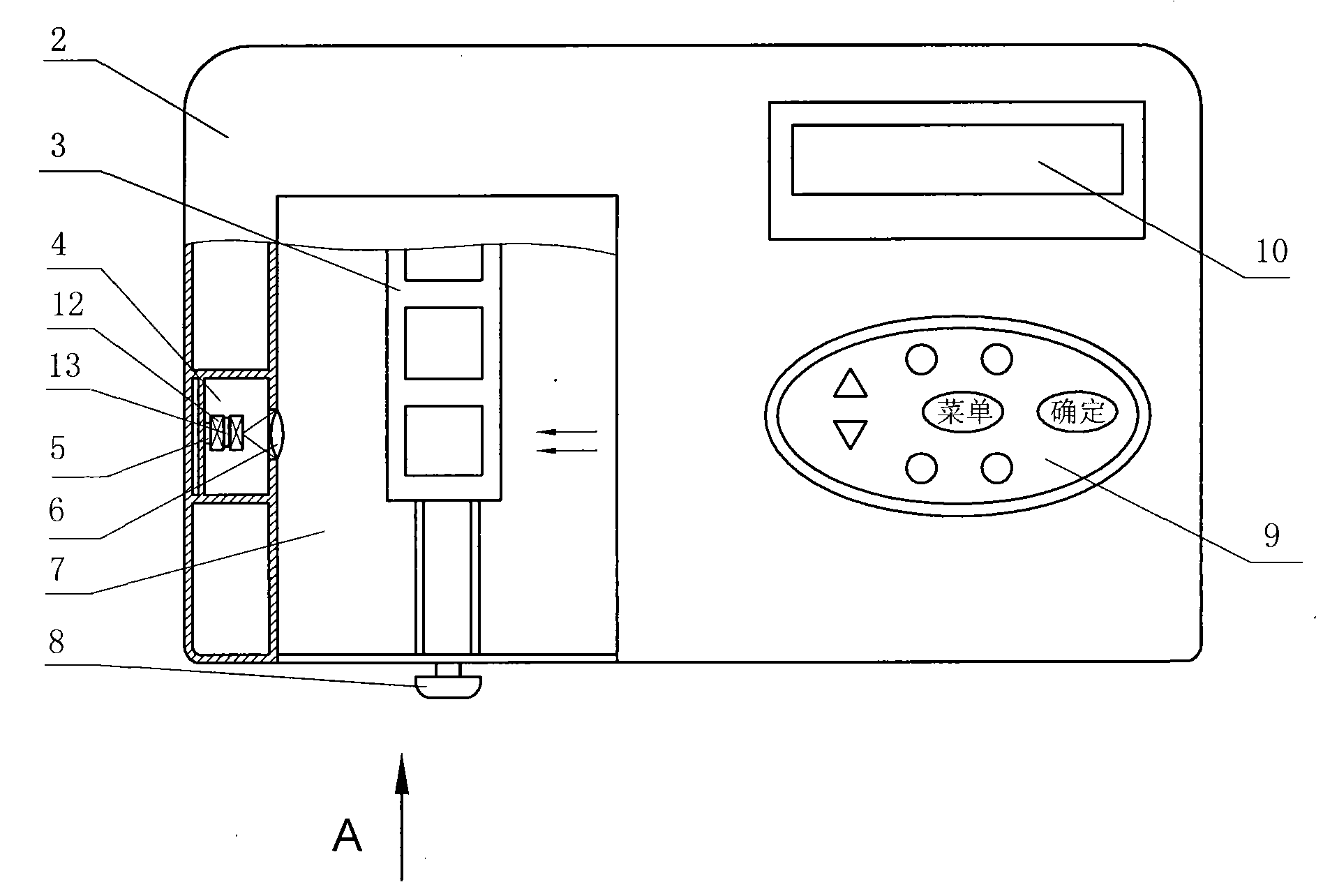

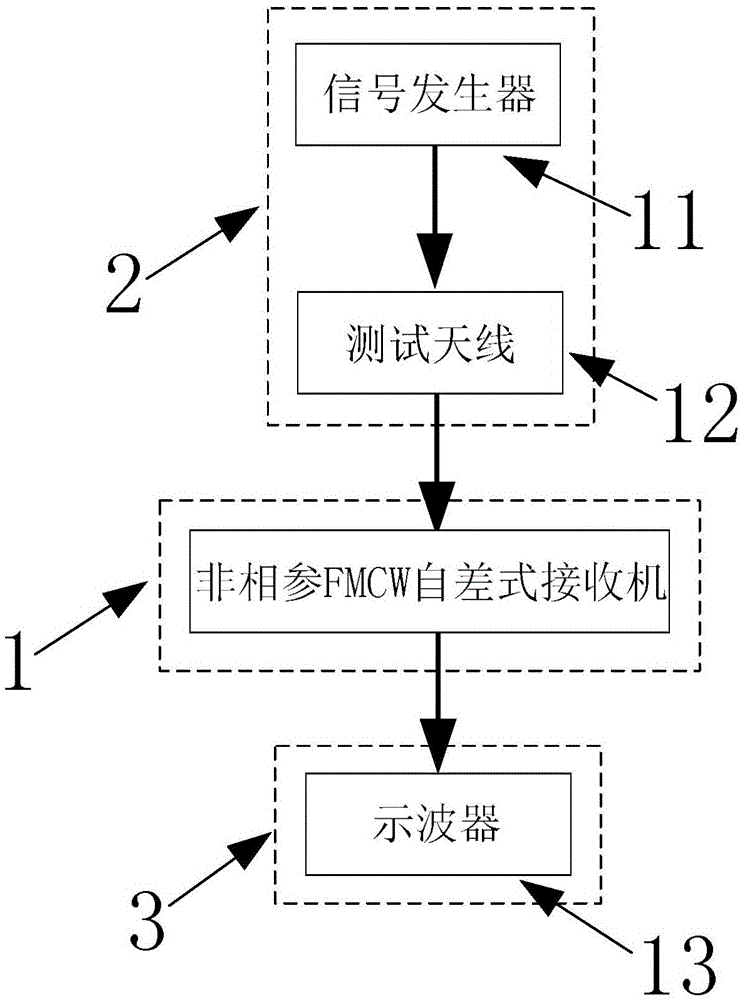

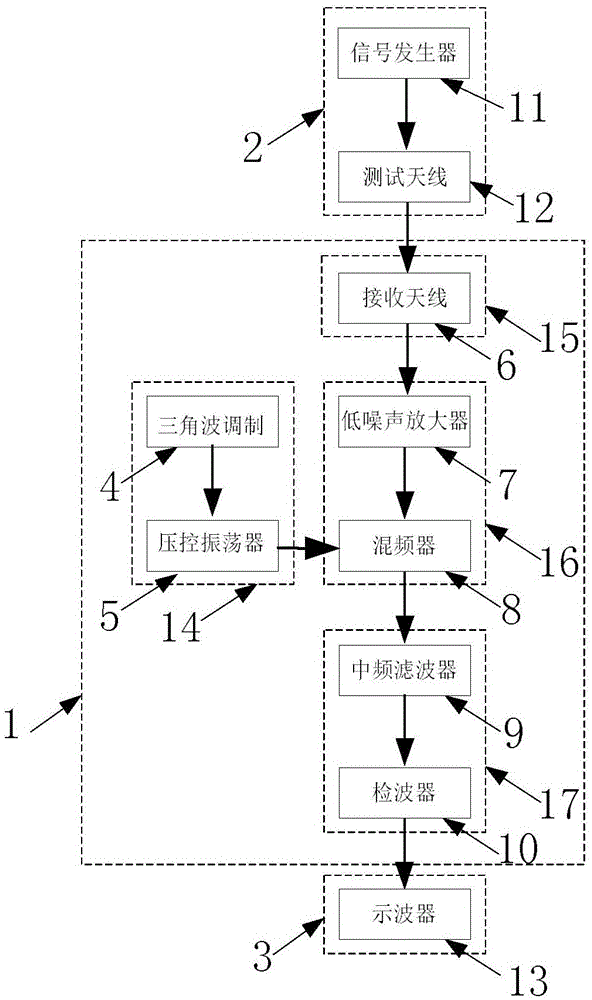

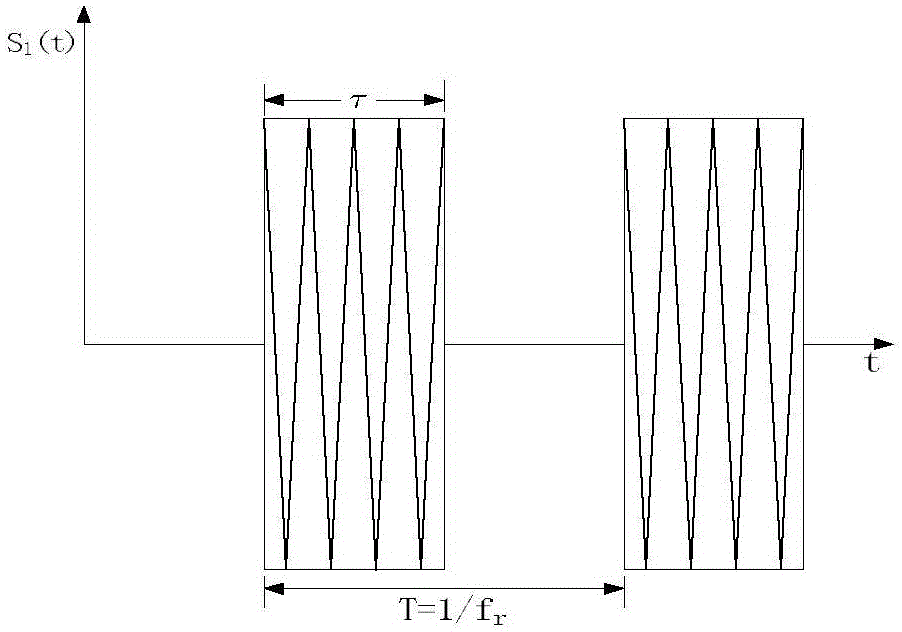

Quantitative testing for sensitivity of a non-coherent FMCW autodyne receiver

The invention discloses a method for testing sensitivity of a non-coherent FMCW autodyne receiver. Firstly, a power stepping value covering initial power of a minimum signal which can be received by a receiver in practical working and satisfies a precision requirement in practical working is set in a standard signal-generator; the signal-generator is arranged to be of an internal pulse modulation mode so as to generate test signals of the non-coherent FMCW autodyne receiver; test signals generated by the signal-generator are feed into the non-coherent FMCW autodyne receiver via a test antenna, and are subjected to detection in a detector in the non-coherent FMCW autodyne receiver; a direct current demodulation voltage signal Vd is output in real time to be displayed on an oscilloscope; the Vd is read out on the oscilloscope to be compared with a preset threshold magnitude of voltage VG; if the Vd=VG, a test person records the present signal source output power Prf; and the sensitivity of the non-coherent FMCW autodyne receiver is calculated according to the Prf. According to the invention, problems that the sensitivity of the autodyne receiver can not be accurately tested due to frequency temperature drift of frequency temperatures of a built-in VCO of the non-coherent FMCW autodyne receiver are solved.

Owner:10TH RES INST OF CETC

Optical lens optical axis thermal stability testing device and method

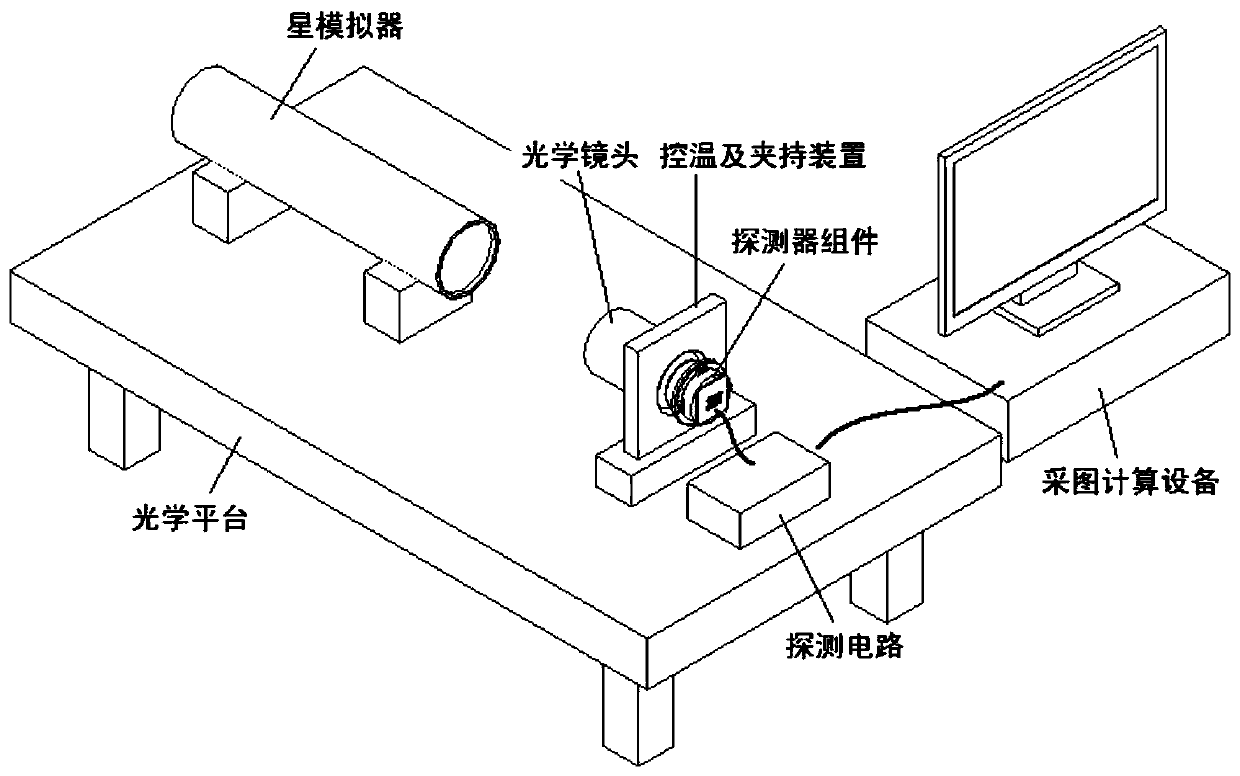

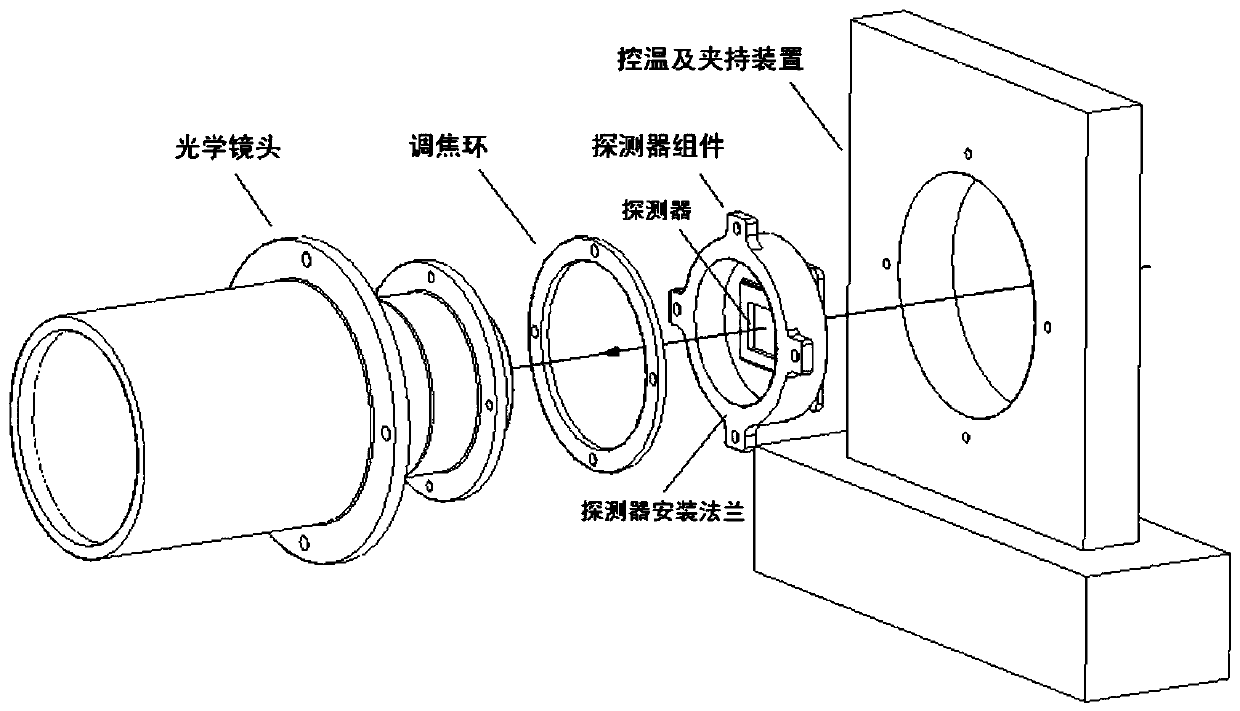

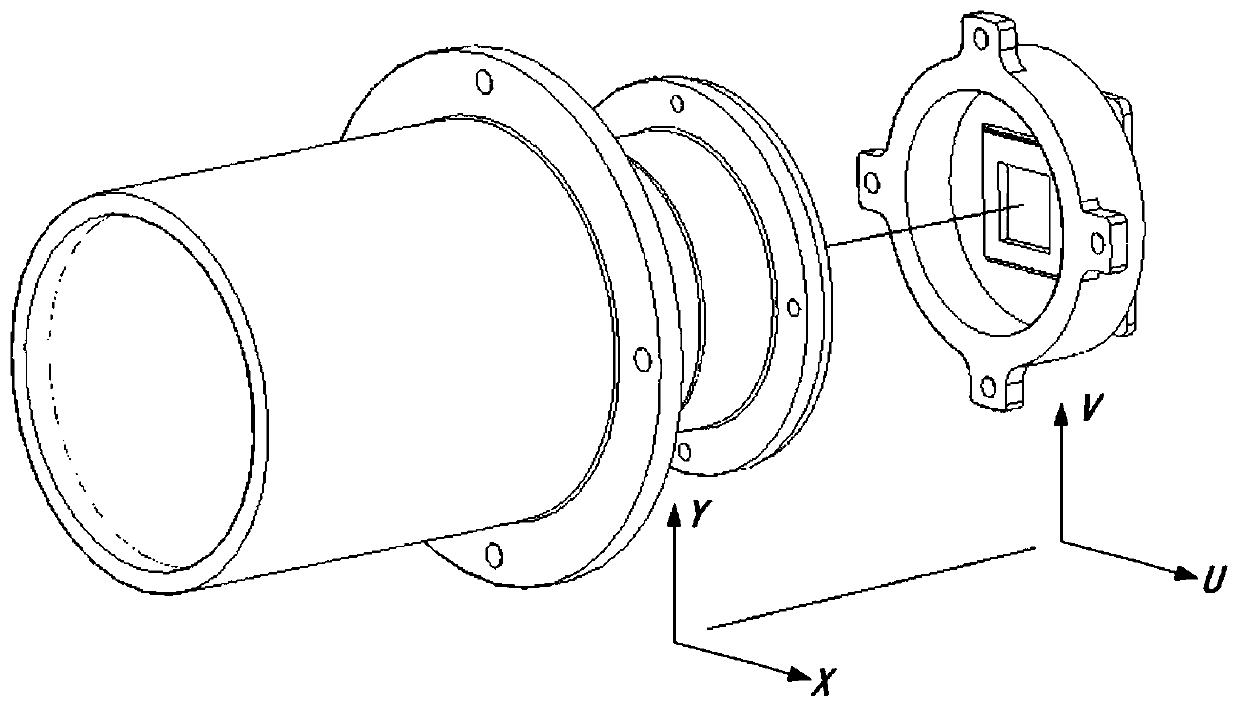

ActiveCN111323210AAccurately measure thermal stabilityAccurate measurement of driftGeometric properties/aberration measurementTemperature controlOptical axis

The invention discloses an optical lens optical axis thermal stability testing device and method. The device comprises an optical platform, a star simulator, an imaging assembly, a temperature controland clamping device, a detection circuit and image acquisition and calculation equipment. The imaging assembly comprises an optical lens and a detector assembly. The star simulator, the imaging assembly and the temperature control and clamping device are all arranged on the optical platform during testing; light emitted by the star simulator is imaged on a detector assembly in the imaging assembly; the temperature control and clamping device is used for clamping the imaging assembly, and a temperature change of the imaging assembly is controlled through an electric heating piece or an oil waypipeline facility arranged in the temperature control and clamping device; the optical lens in the imaging assembly is used as a tested unit in the test to converge target source light and image on the detector assembly; the detection circuit is connected with a detector assembly in the imaging assembly and is used for forming control and output of images; and the image acquisition and calculation equipment is connected with the detection circuit and is used for acquiring, recording, analyzing and calculating the images.

Owner:BEIJING INST OF CONTROL ENG

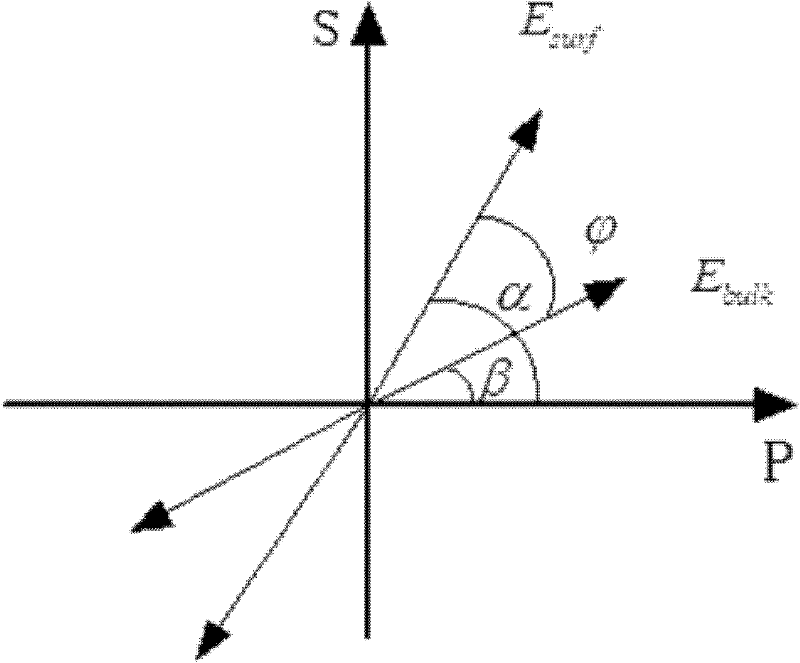

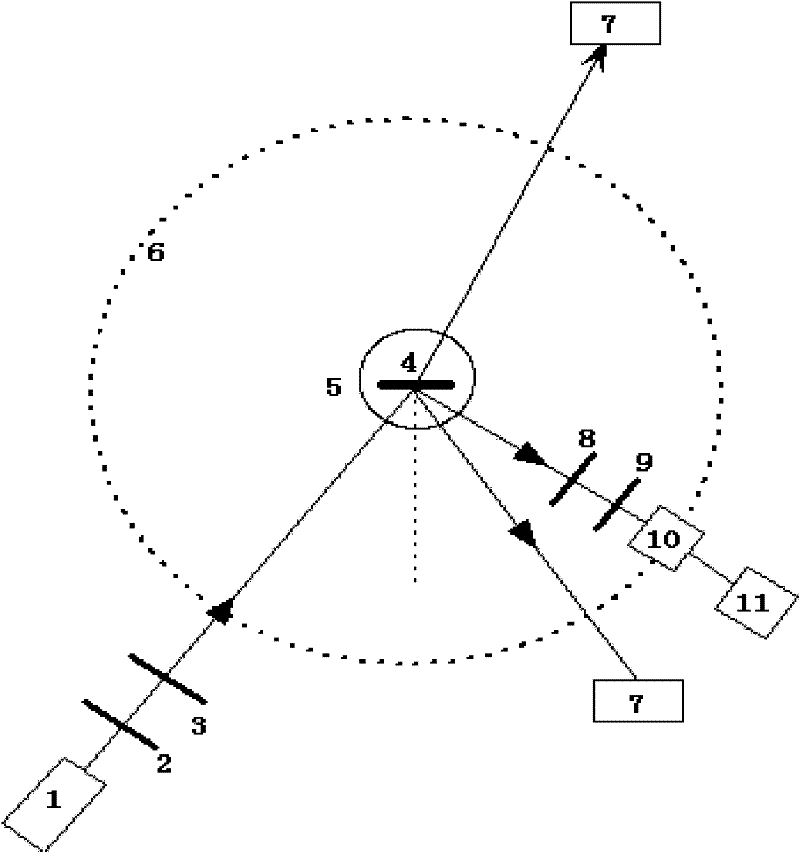

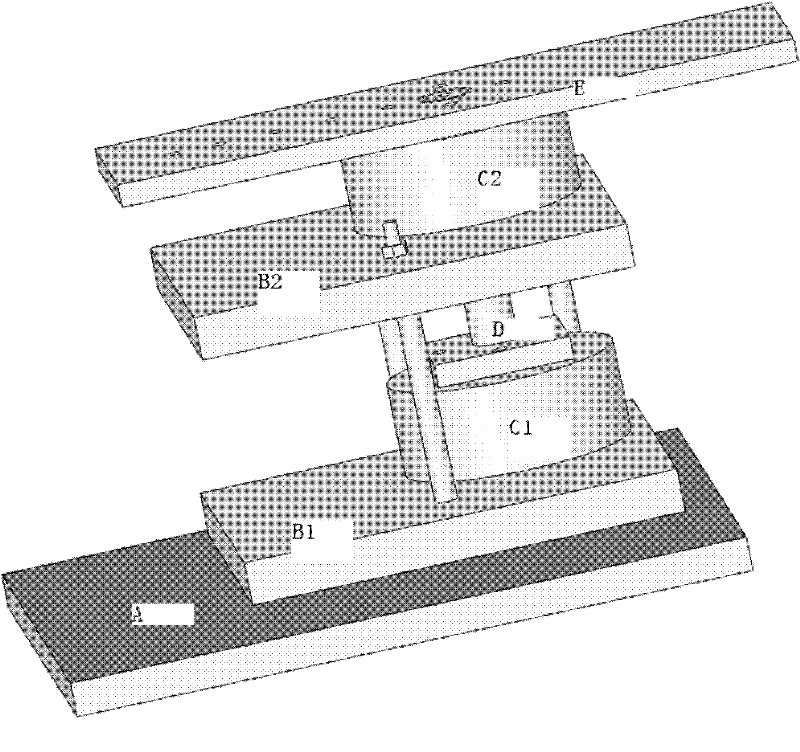

Sub-angstrom-level super-smooth transparent surface test system based on differential scattering

InactiveCN102253004AEliminate test errorsHigh precisionScattering properties measurementsUsing optical meansPhotovoltaic detectorsOptical table

The invention discloses a sub-angstrom-level super-smooth transparent substrate surface test system based on differential scattering. The sub-angstrom-level super-smooth transparent substrate surface test system consists of a light source system, a rotary table system, a sample stage system, a photoelectric detection system and a data collection and display system. In the rotary table system as shown in a figure in the specification, each component is in fully rigid connection; precision rotary tables C1 and C2 are fixed on an optical platform A by standard fastening screws; and a polarization analyzer, a photoelectric detector and the like are fixedly connected onto the precision rotary table C2 by an extension plate of the measurement system. By using the polarization interference principle and regarding the first-order differential scattering perturbation theory as a guideline, suitable polarizing direction and polarization analyzing direction are selected to eliminate the volume scattering of the substrate and effectively and independently measure the microstructure of the sub-angstrom-level super-smooth transparent substrate surface. The sub-angstrom-level super-smooth transparent substrate surface test system based on differential scattering can be used for rapidly and accurately screening fused quartz or microcrystalline glass substrates used in the research and production of high-precision laser gyroscopes, and synchronously, the invention provides a universal method for testing the super-smooth transparent substrate surface.

Owner:杨开勇 +2

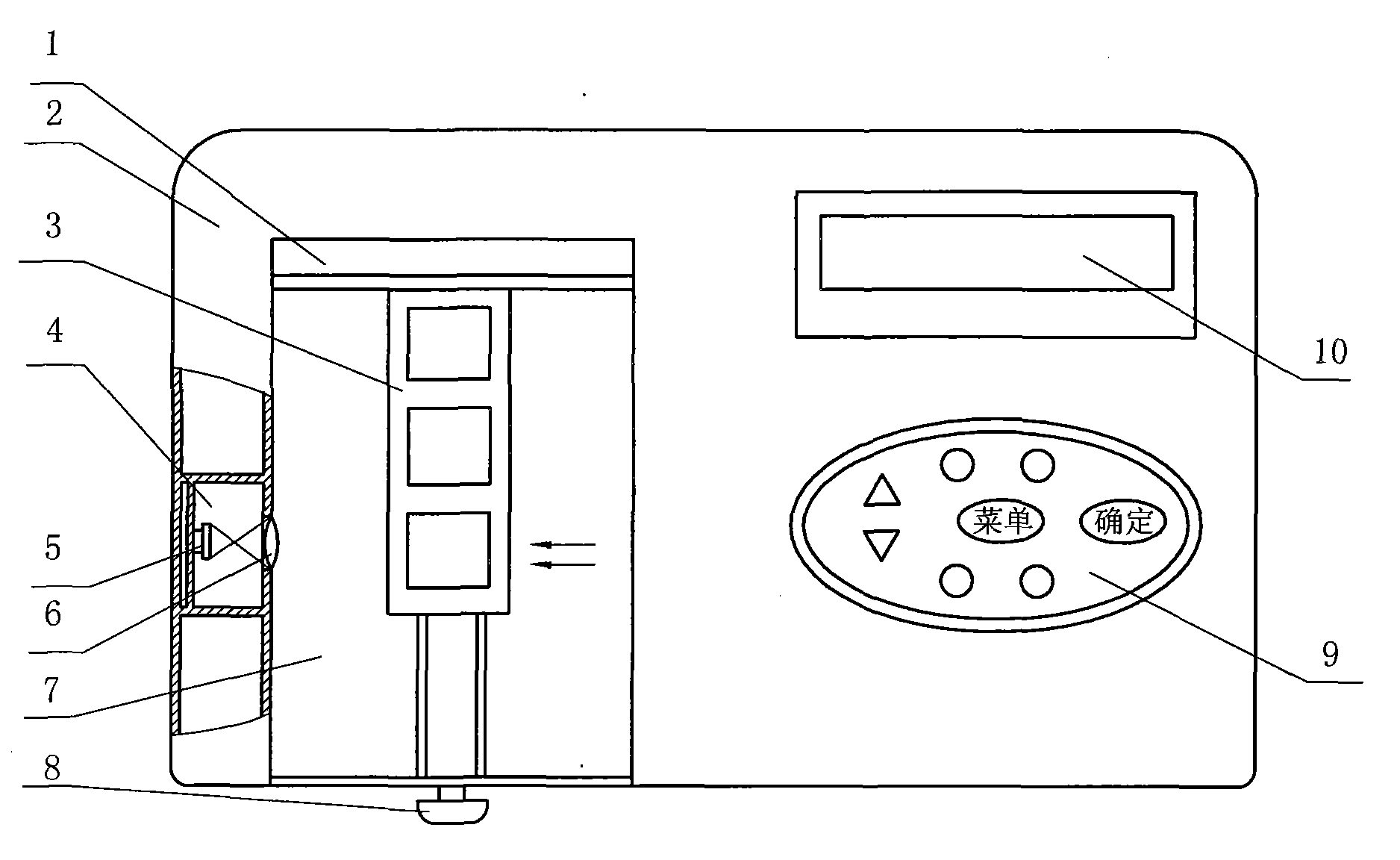

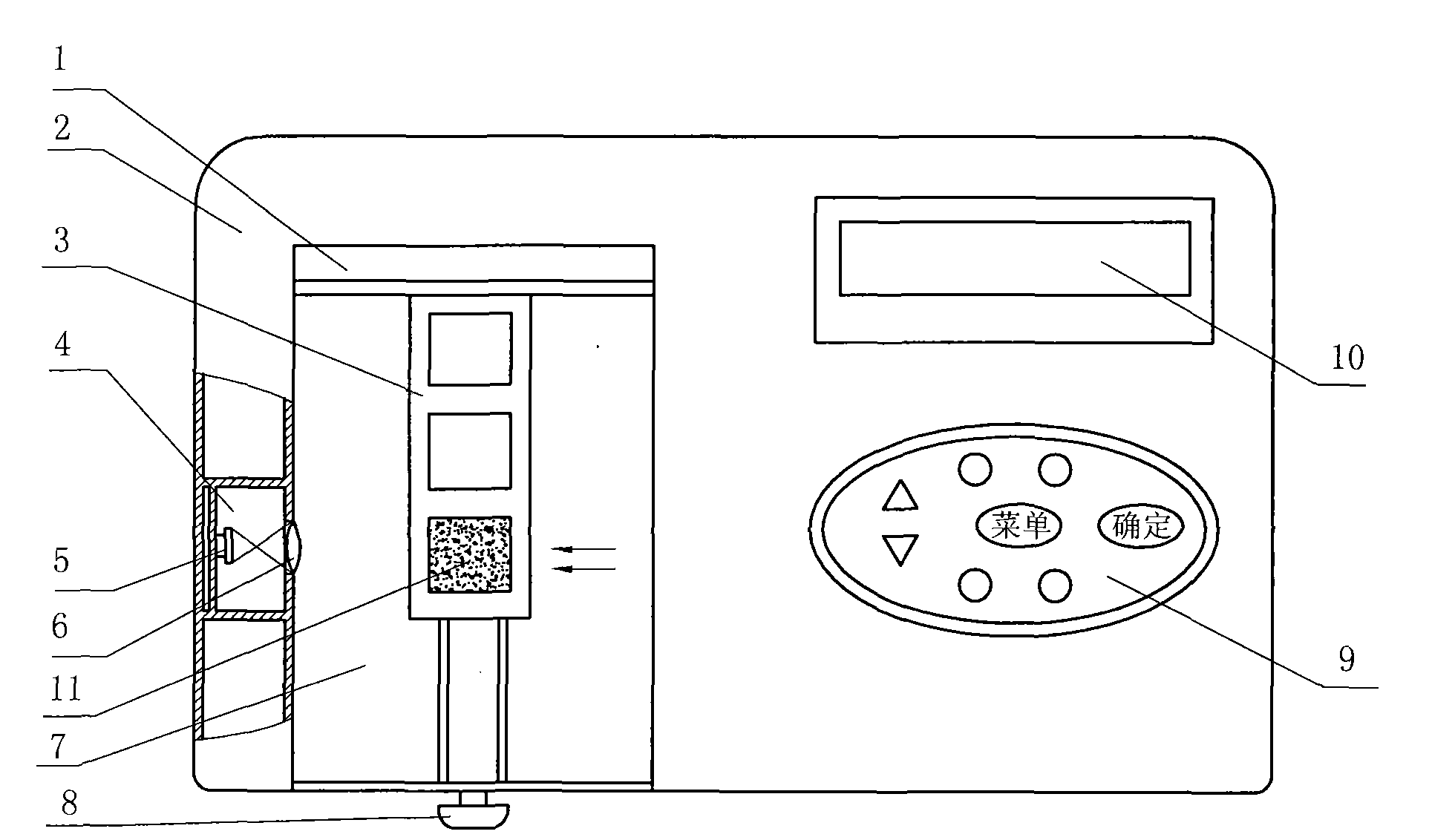

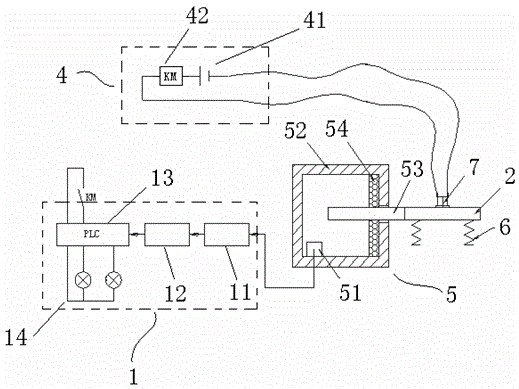

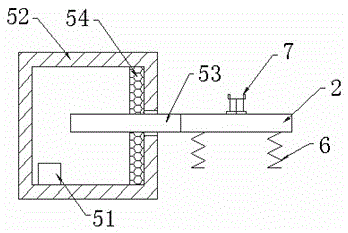

Temperature controller synchronization degree tester and testing method thereof

ActiveCN105589034AReduce labor intensityEliminate test errorsCircuit interrupters testingSynchronous detectionAcoustic sensor

The purpose of the invention is to provide a temperature controller synchronization degree tester and a testing method thereof. The temperature controller synchronization degree tester is used for detecting the synchronization of a snap-action temperature controller in order to increase detection accuracy and efficiency and decrease the labor intensity of workers. The temperature controller synchronization degree tester comprises a control device, a switch-off synchronization detection board, and a switch-on synchronization detection board. A heater is disposed in the switch-off synchronization detection board. Each of the switch-off synchronization detection board and the switch-on synchronization detection board is provided with a state detecting device and a sensing device. Each sensing device comprises a sound sensor and / or a vibration sensor and is connected with the control device. Each state detecting device is composed of a power supply and relay. One end of each power supply is connected with a first terminal clip and the other end of the power supply is connected with the first control end of the corresponding relay. The second control end of each relay is connected with a second terminal clip. The two terminals of the output circuit of each relay are connected with the control device.

Owner:GUANGDONG HUATIAN ELECTRICAL APPLIANCE +4

Radio-frequency device test probe with built-in inductor

PendingCN109001500AEliminate test errorsReduce volatilityElectrical measurement instrument detailsElectrical testingInsulation layerInductor

The invention discloses a radio-frequency device test probe with a built-in inductor. The radio-frequency device test probe with the built-in inductor comprises a substrate metal layer and an insulation layer; the insulation layer is arranged at the upper side of the substrate metal layer; a first metal layer is arranged on the top of the insulation layer at intervals; the first metal layer comprises first metal, second metal, third metal and fourth metal; the first metal, the second metal and the third metal are separately connected to metal probes; the metal probes are separately connected with the signal input end, the signal output end and the grounding end of a radio-frequency device to be tested; the other ends of the first metal and the second metal are connected with the signal output end of a network analyzer through a cable; the other end of the third metal is connected to the second metal layer, so that a bipolar inductor is formed; the other end of the second metal layer isconnected with one end of the fourth metal; and the other end of the fourth metal is grounded. According to the radio-frequency device test probe with the built-in inductor in the invention, the testerror and the fluctuation performance due to the cable and the network analyzer can be eliminated; the test precision is improved; and the test accuracy is improved.

Owner:HUAIYIN TEACHERS COLLEGE

Environment-friendly polyaniline anti-corrosion and anti-shedding coating

InactiveCN104341960AHigh hardnessImprove wear resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyEthylene glycol bis

The invention discloses an environment-friendly polyaniline anti-corrosion and anti-shedding coating. The coating comprises a component A and a component B, wherein the weight ratio of the component A to the component B is (10 to 1)-(20 to 1); the component A is prepared from the following components: (1) 53g of liquid epoxy resin E56, (2) 6g of diethylene glycol dibenzoate, (3) 0.5g of OP-10, (4) 10g of n-amyl alcohol, (5) 3g of ammonium persulfate, (6) 1.5g of distilled water, (7) 1g of 0.4mol / L camphorsulfonic acid water solution, (8) 10g of aniline, (9) 0.5g of methyl silicone oil and (10) 7g of neopentyl glycol diglycidyl ether; the component B comprises the following components: 110g of liquid fatty polyamine, 30g of polyaniline, 5g of quartz sand, 10g of ethylene glycol phenyl ether, 5g of talcum powder and 5g of rosin glycerin ester. The coating has the advantages of high polyaniline content, good anti-corrosion property, no pollution, low cost, and the like.

Owner:QINGDAO YIQUN PANT GRP

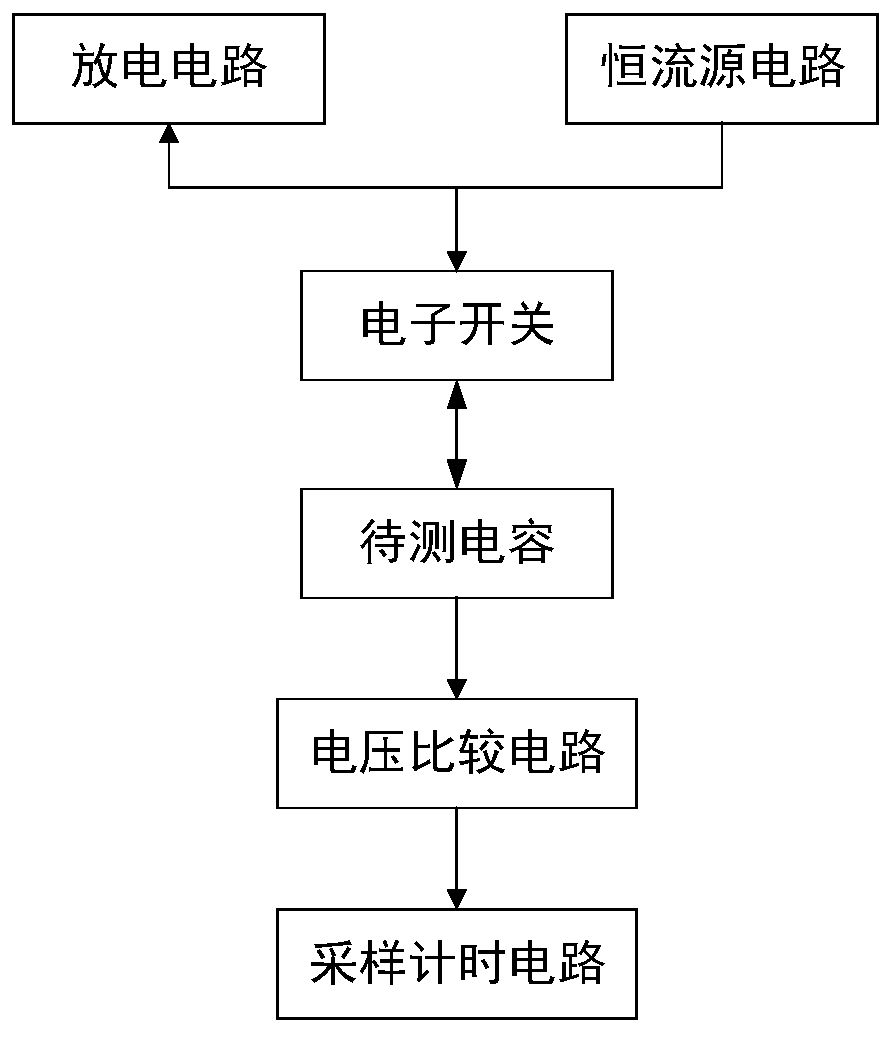

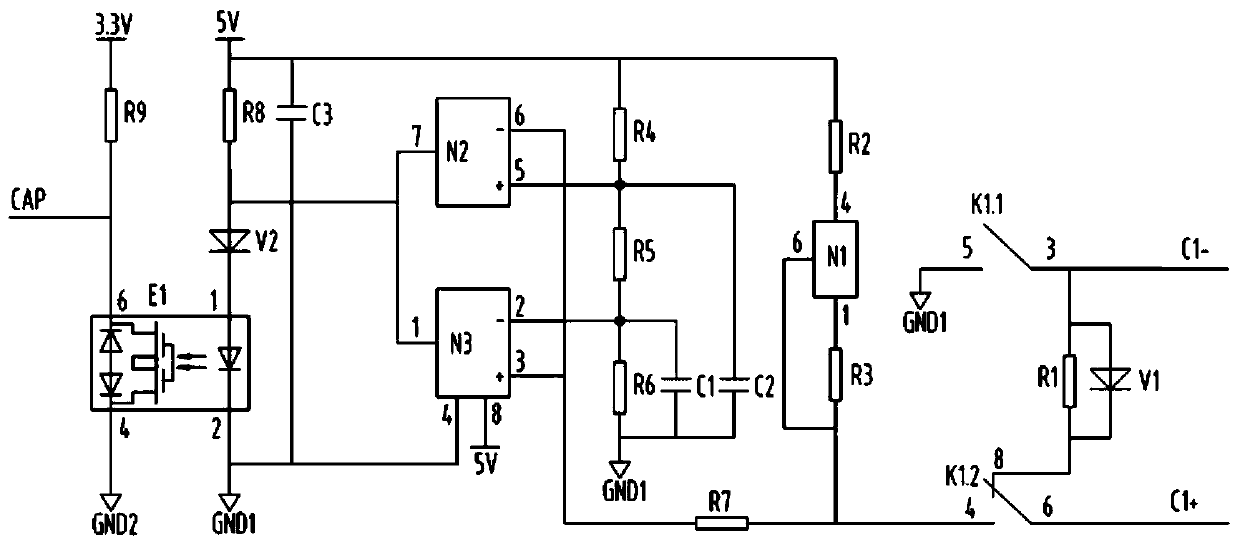

Capacitor test circuit

InactiveCN109856461AEliminate test errorsImprove accuracyResistance/reactance/impedenceConstant current sourceCapacitance

The invention discloses a capacitor test circuit. The circuit comprises a constant-current source circuit, a voltage comparison circuit and a sampling timing circuit; the constant-current source circuit is used for generating constant charging current to charge a capacitor to be tested; the voltage comparison circuit is used for acquiring the output voltage of the capacitor to be tested, and outputting control signals when the output voltage is greater than a preset first voltage and smaller than a preset second voltage, wherein the control signals are used for triggering the sampling timing circuit to generate sampling signals; and the sampling timing circuit is used for recording the lasting time of the sampling signals, and calculating the capacitance value of the capacitor to be testedaccording to the charging current, the difference value of the second voltage and the first voltage, and a timing result. According to the capacitor test circuit of the present invention, the first voltage, replacing a zero voltage, is adopted as the initial value of the start of timing, and therefore, test errors caused by a condition that a voltage zero position is susceptible to interference can be eliminated, and the accuracy of test results can be improved.

Owner:湖北三江航天红林探控有限公司

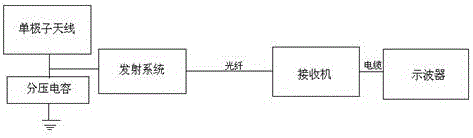

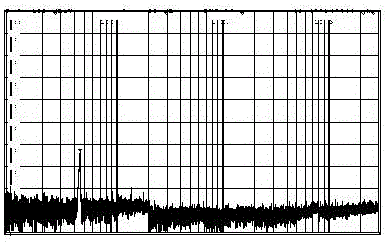

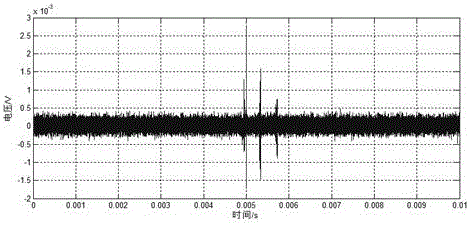

Train inside static magnetic field test and running state analysis apparatus and analysis method

ActiveCN105717372AEasy to locate the source of disturbanceEliminate test errorsElectromagentic field characteristicsMeasuring interference from external sourcesMonopole antennaVIT signals

The invention relates to a train inside static magnetic field test and running state analysis apparatus and analysis method. The train inside static magnetic field test and running state analysis apparatus comprises a monopole antenna, a voltage-dividing capacitor, an emission system, a receiver and an oscilloscope. The monopole antenna, after performing voltage division on received signals through the voltage-dividing capacitor, inputting the signals into the emission system, the emission system transmits the signals to the receiver through fibers, and the receiver transmits the signals to the oscilloscope for display through cables. According to the invention, through manufacturing the monopole antenna, a test system is erected, the monopole antenna is calibrated, the electromagnetic field intensity inside a train is tested, data is obtained, compensation processing is performed, waveforms are reconstructed, and waveform distortion is reduced.

Owner:CRRC NANJING PUZHEN CO LTD

Virtual instrument-based motor control automatic testing system and method for electric automobile

ActiveCN102147619BGuaranteed synchronous samplingAcquisition speed is fastElectric testing/monitoringArea networkPCI eXtensions for Instrumentation

The invention provides a virtual instrument-based motor control automatic testing system and method for an electric automobile, wherein the system comprises an industrial personal computer and a CAN (controller area network) communication bus connected with the industrial personal computer, a test setting unit, a data processing unit, a result display unit and a database management unit which areall connected with the industrial personal computer, a data collecting unit respectively connected with a motor control circuit to be tested and the industrial personal computer, and a PXI (PCI Extensions for Instrumentation) communication card respectively connected with the industrial personal computer and the CAN communication bus; a programmable power supply is connected with the motor control circuit to be tested; and the motor control circuit to be tested is respectively connected with the data collecting unit and the CAN communication bus. The method comprises the steps of: selecting test items and setting parameters; collecting testing signals; analyzing and processing test data; displaying a testing result; and updating and managing a database. By the automatic testing system andmethod, the function detection and the collecting, processing and storing of the testing data of an electric automobile motor control circuit can be completed automatically; the synchronous sampling of the testing data is ensured; the automatic testing system and method have high testing precision and good the repeatability is good; the testing error is reduced; and the automatic level of the detection is improved.

Owner:TIANJIN QINGYUAN ELECTRIC VEHICLE

A kind of spectral confocal lens center thickness measurement method and device

The invention relates to a method and a device for measuring the center thickness of a spectral confocal lens. The existing methods and devices have large errors and time-consuming measurements. The measuring method is to use an area array camera and a TV image to assist in centering, and then use a spectral confocal method to measure the center thickness of the optical lens, which ensures the correctness of the measuring object and greatly improves the accuracy of the test results. The device of the invention expands a monitoring optical path in the spectral confocal measurement lens thickness, the centering optical path and the measuring optical path have high coincidence degree, reduce unnecessary hardware waste, and effectively control the cost of the device.

Owner:XIAN TECH UNIV

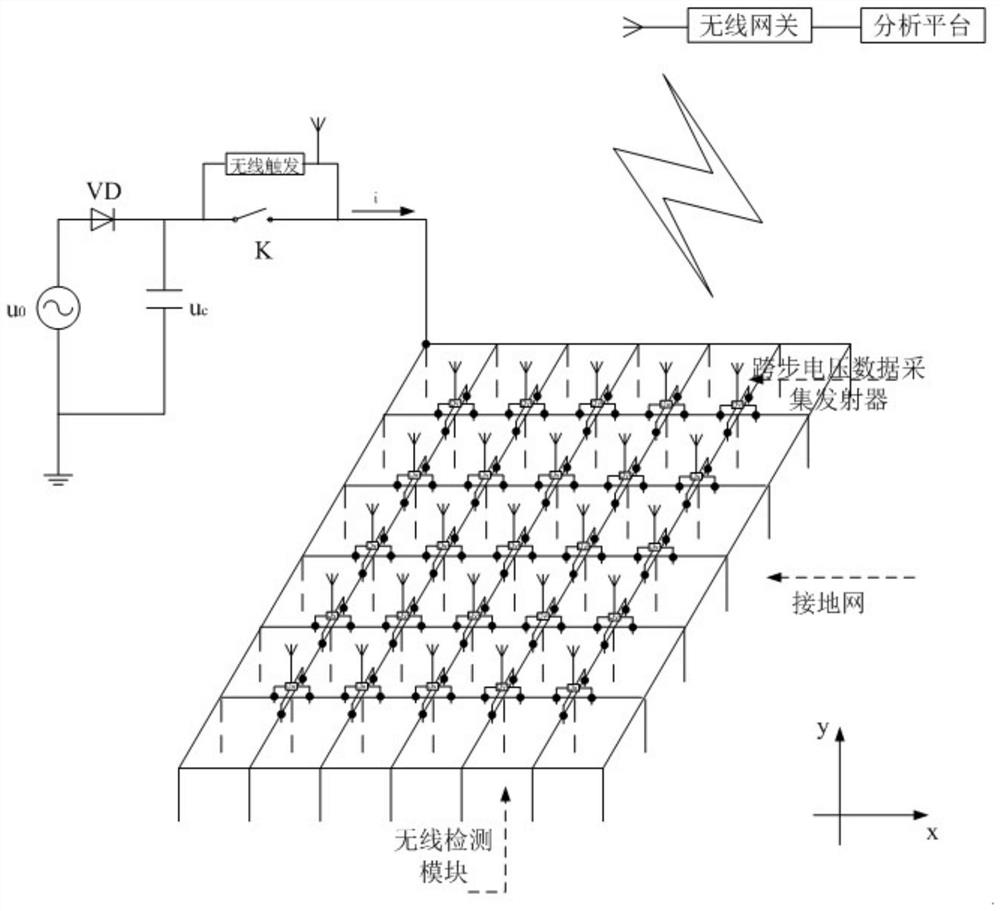

Grounding grid performance detection method and system based on wireless sensor network

PendingCN112782610ASimple structureFast testTransmission systemsShort-circuit testingGrounding gridMeteorology

The invention discloses a grounding grid performance detection method and system based on a wireless sensor network. The detection system is simple in structure. Multiple groups of test data can be obtained simultaneously through one test, the test speed is high, and the efficiency is high. The data is analyzed and calculated through the analysis platform, step voltage result data of multiple groups of test points can be obtained, so that the purpose of comprehensively examining the performance of the whole earth screen is achieved, and the result is real and comprehensive. According to the method, singular detection points existing in the result can be observed more visually by scanning and measuring the condition of the whole ground net, the ground net is improved more specifically, test errors caused by underground soil, pipe network distribution, damage to a part of the ground net and other factors can be effectively eliminated, the condition of the ground net is effectively and truly reflected, and the method has high accuracy.

Owner:STATE GRID TIANJIN ELECTRIC POWER +1

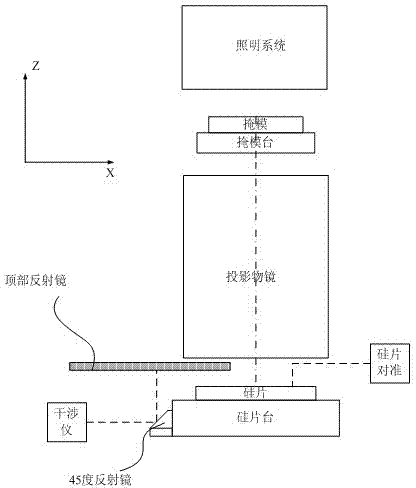

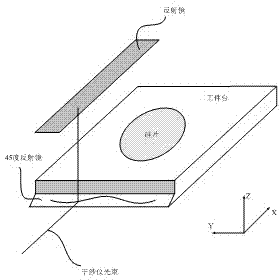

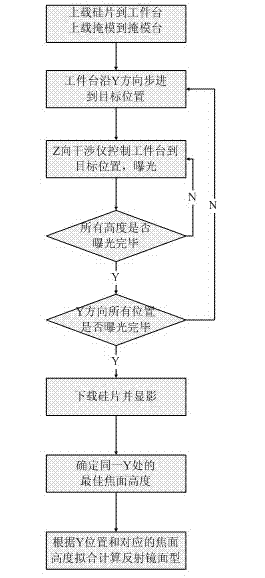

Method used for measuring photoetching machine vertical measuring system reflector surface shape

ActiveCN104777715AEliminate test errorsHigh precisionUsing optical meansPhotomechanical exposure apparatusFocal positionOptoelectronics

The invention provides a method used for measuring photoetching machine vertical measuring system reflector surface shape. The method comprises following steps: 1) a substrate is uploaded onto a workpiece table, and a reticle mask with confirmable optimum focal plane marks is uploaded onto a reticle stage; 2) the Y direction position of the workpiece table is maintained to be unchanged, n times of stepping on the Z direction of the workpiece table are realized via controlling by an interferometer, wherein after each time of stepping of the workpiece table, stepping of a same space on the X direction is carried out, so that exposure of the confirmable optimum focal plane marks of the reticle mask onto the substrate is realized; 3) after n times of height exposure, stepping of one space of the workpiece table on the Y direction is realized, and the step 2) is repeated until exposure of the whole substrate is realized, and exposure of m groups of masks is realized; 4) the substrate is subjected to development and drying, and is uploaded onto the workpiece table, and reading of alignment positions of n*m masks is carried out; 5) alignment offset of the masks is calculated based on the alignment positions, the optimum focal position BF of yi at each Y-direction is obtained via calculation based on the relationship of the alignment positions with defocusing amount, so that changing amount of the optimum focal position is represented by a formula in the invention, and whererin F-T are used for representing the workpiece table positions; 6) fitting of the reflector surface shape is carried out based on the m positions yi, and distance <delta>hi of actual positions of the corresponding reflector surface shape to the nominal positions.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

Flame retardant anti-corrosion environment-friendly polyaniline coating

InactiveCN104341974AHigh hardnessImprove wear resistanceFireproof paintsAnti-corrosive paintsPhenyl EthersTurpentine

The invention discloses a flame retardant anti-corrosion environment-friendly polyaniline coating. The coating comprises a component A and a component B, wherein the weight ratio of the component A to the component B is (10 to 1)-(20 to 1); the component A is prepared from the following components: (1) 70g of liquid epoxy resin E44, (2) 24g of dioctyl phthalate, (3) 2.5g of OP-10, (4) 8g of n-butyl alcohol, (5) 4g of ammonium persulfate, (6) 2g of distilled water, (7) 0.5g of 0.8mol / L camphorsulfonic acid water solution, (8) 6g of aniline, (9) 0.8g of methyl silicone oil and (10) 4g of neopentyl glycol diglycidyl ether; the component B comprises the following components: 140g of liquid fatty polyamine, 10g of polyaniline, 10g of xanthan gum, 7g of ethylene glycol phenyl ether, 12g of methylcellulose and 3g of turpentine silicone oil. The coating has the advantages of high polyaniline content, good anti-corrosion property, no pollution, low cost, and the like.

Owner:QINGDAO YIQUN PANT GRP

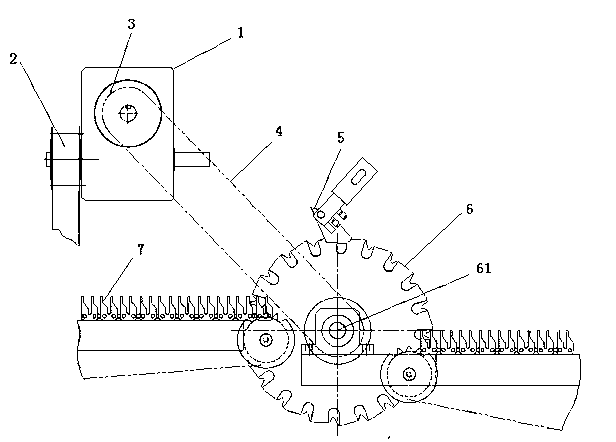

Thermistor static test sorting machine

InactiveCN103272785AEliminate test errorsImprove reliabilitySortingElectrical resistance and conductanceHeat sensitive

The invention discloses a thermistor static test sorting machine, comprising a transmission chain, a test piece, a test wheel shaft, a test wheel rotating together with the test wheel shaft and taking a to-be-tested element from the transmission chain to the test piece, and a slicer capable of transferring continuous rotation input into interval rotation and static, wherein the slicer comprises an input wheel and an output wheel which is connected together with the test wheel shaft through a timing belt pulley. The test of the to-be-tested element is changed from a dynamic test into a static test, so that test error produced by relative movement between the to-be-tested element and the test piece is eliminated; and reliability of the test results is increased.

Owner:太仓市晨启电子精密机械有限公司

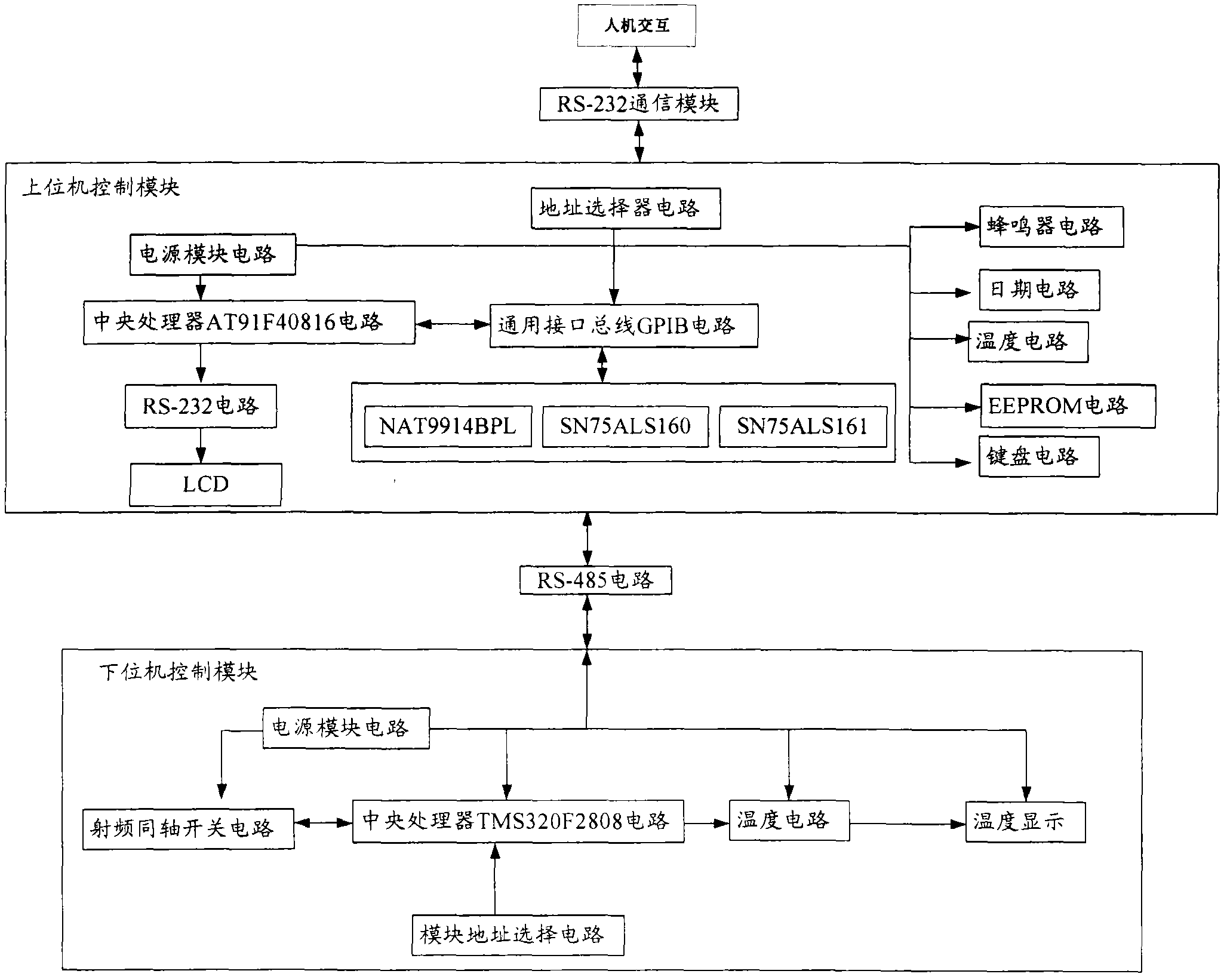

Radio-frequency switching unit control method based on ARM (advanced reduced instruction set computer machine) and DSP (digital signal processor)

InactiveCN102621913AEliminate test errorsImprove detection efficiencyProgramme controlComputer controlAutomatic controlRadio frequency

A radio-frequency switching unit control method based on an ARM (advanced reduced instruction set computer machine) and a DSP (digital signal processor) mainly includes a control procedure of a lower computer control unit of a radio-frequency automatic control system and a control procedure of an upper computer control unit of the radio-frequency automatic control system. The control procedure of the lower computer control unit mainly includes the steps: initializing a power source and a central processor, setting a module address selection circuit module, using the central processor to analyze data transmitted by an upper computer, and the like. The control procedure of the upper computer control unit mainly includes the steps: initializing a power source, a GPIB (general purpose interface bus), initializing the central processor, using the central processor for read-write operations according to the GPIB bus, and the like. The radio-frequency switching unit control method is implemented by means of mutual data interaction between an upper computer module and a lower computer module. The radio-frequency switching unit control method has the advantages of simplicity, feasibility and flexibility in operation.

Owner:RADIOSKY TESTING SERVICES BEIJINGLTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com