Sub-angstrom-level super-smooth transparent surface test system based on differential scattering

An ultra-smooth surface and ultra-smooth technology, which is applied in the field of optical detection, can solve problems such as weak surface scattering, measurement data that cannot truly reflect the microstructure information of the substrate surface, and surface scatterers being submerged by scattering, so as to suppress volume scattering and ensure long-term Time stable operation, precise and controllable repeatability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

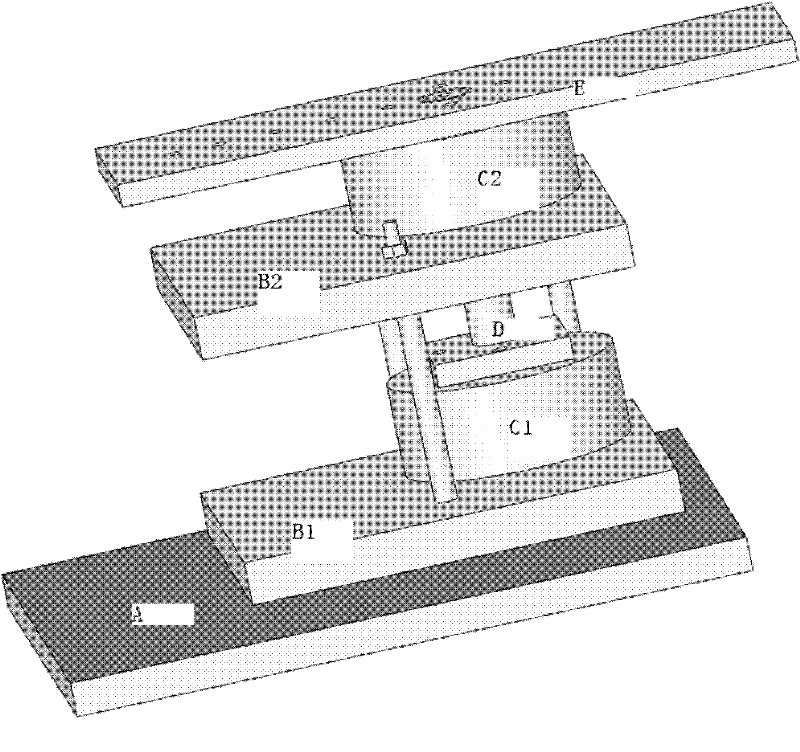

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings.

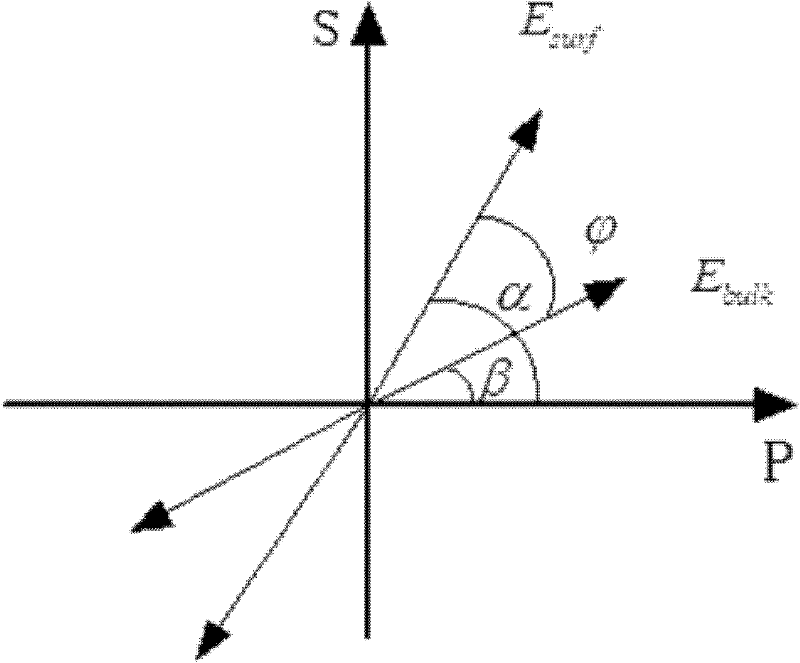

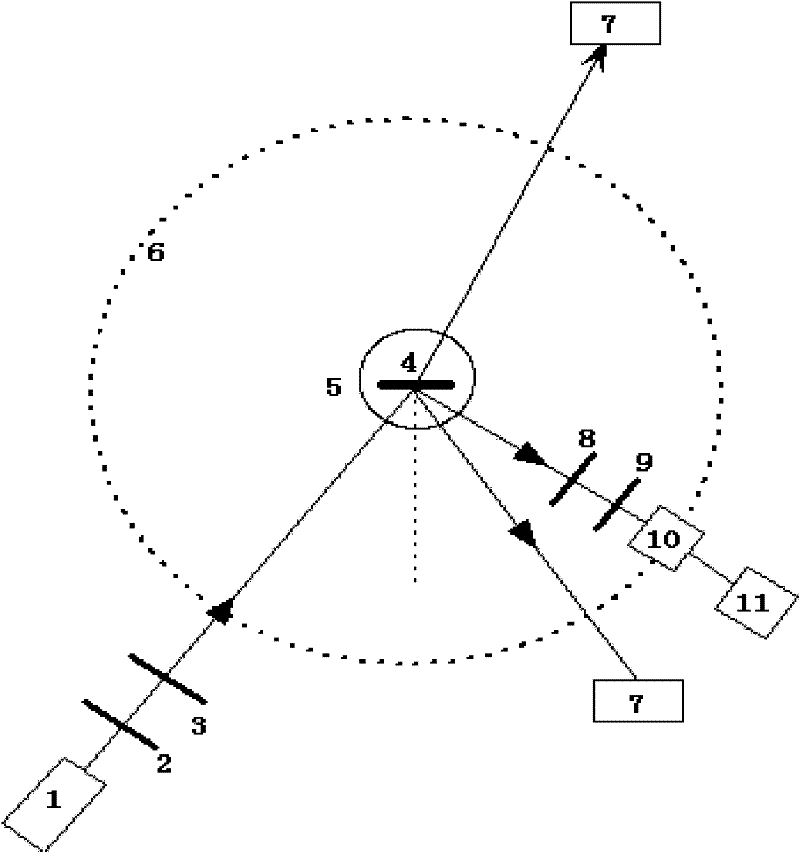

[0014] When optically inspecting the surface of a sub-Angstrom ultra-smooth transparent substrate, the differential scattering power of the substrate’s surface scattering and volume scattering will be coupled together, resulting in the measured surface scattering data not being able to fully reflect the microscopic shape of the substrate surface. features. Relevant studies have shown that, for the case where the scattering plane is located in the incident plane, the polarization directions of surface scattering and volume scattering light will present a certain angle in the s-p plane, as figure 1 As shown, let the surface scattered light The angle between the polarization direction and the p-axis is , volume scattered light The angle between the polarization direction of and the p-axis is , the difference between the two. In order to eliminate the ef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com