Thermistor static test sorting machine

A thermistor and sorter technology, applied in sorting and other directions, can solve problems such as test errors, achieve the effect of improving reliability and eliminating test errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

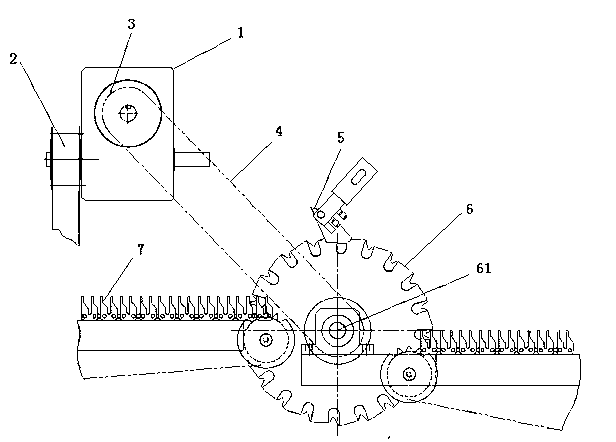

[0012] like figure 1 As shown, the thermistor static test sorting machine includes: a transmission chain 7, a test piece 5, a test wheel shaft 61, and a test wheel 6 that rotates with the test wheel shaft 61 and brings the tested original from the transmission chain 7 to the test piece 5 , also includes a cam splitter 1 that can convert continuous rotation input into interval rotation and stationary, cam splitter 1 includes: input wheel 2 and output wheel 3, output wheel 3 is connected with test wheel shaft 61 through timing belt 4 .

[0013] Working principle: With the above-mentioned equipment, the main drive is input through the input wheel 2 of the splitter, and the output wheel 3 of the splitter drags the test wheel shaft 61 through the synchronous belt 4, and the test wheel 6 that rotates with the test wheel shaft 61 drives the tested component from the transmission The chain 7 is brought under the test piece 5 and tested when the test wheel 6 is stationary.

[0014] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com