A kind of spectral confocal lens center thickness measurement method and device

A lens center, spectral confocal technology, applied in the field of optical detection, can solve problems such as large errors, and achieve the effects of eliminating test errors, controlling costs, and accurate centering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

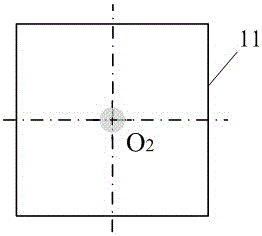

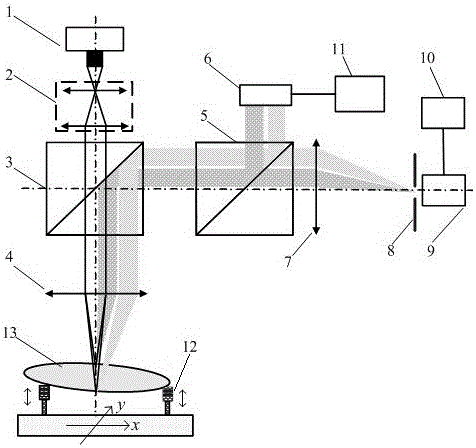

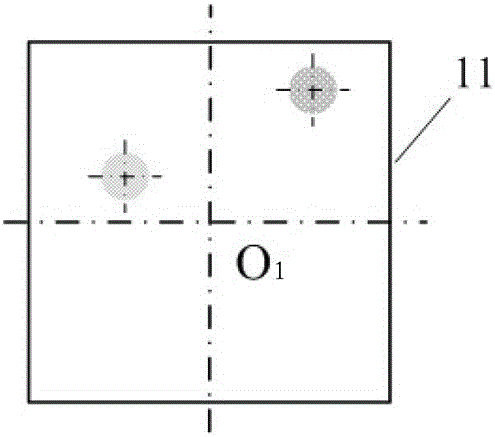

[0032]Measurement example of biconvex lens center thickness

[0033] Such as figure 1 As shown, a spectral confocal lens center thickness measurement method, the measurement steps are:

[0034] (1) According to the caliber of the measured lens, select and install the matching adjustable lens loading platform; place the tested lens 13 on the adjustable lens loading platform;

[0035] (2) Turn on the light source. The light emitted by the broadband light source 1 passes through the first achromatic beam expander and collimator optical lens 2 to form a broadband parallel beam. The light of different wavelengths has no phase difference, and the parallel light enters the dispersion after passing through the first dichroic prism 3 Lens group 4, light of different wavelengths produces spectral dispersion, forms a series of focal points in space and focuses on different quasi-monochromatic lights on the front and rear surfaces of the measured double-convex lens 13 with a certain amou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com