Temperature controller synchronization degree tester and testing method thereof

A temperature controller and tester technology, which is applied in circuit breaker testing, instrumentation, electrical measurement, etc., can solve problems such as low product detection accuracy and judgment errors, so as to prevent inattention, reduce labor intensity, and facilitate promotion value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

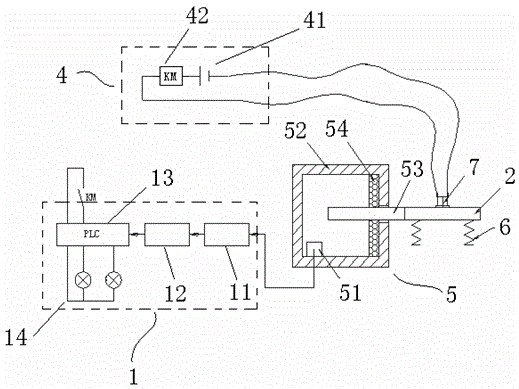

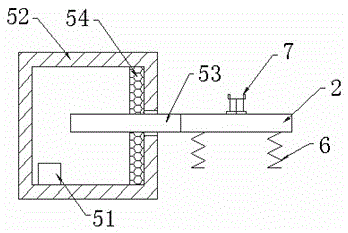

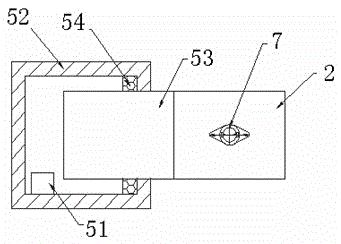

[0027] As shown in the figure, the temperature controller synchronization degree tester of this embodiment is composed of a control device 1, a disconnection synchronization detection board 2 and a closure synchronization detection board 3. A heater is arranged inside the disconnection synchronization detection board 2. The heater is composed of a heating wire and a thermal resistance thermometer to control the temperature of the disconnection synchronous detection board 2 at about 1.2 times of the rated temperature of the thermostat; the disconnection synchronous detection board 2 and the closed synchronous detection board 3 are all set State detection device 4, sensing device 5; Described sensing device 5 comprises sound sensor 51; Sound sensor 51 is connected with control device 1, and the sound that senses is sent to control device 1; Described state detection device 4 is controlled by power supply 41 and A relay 42 is formed, one end of the power supply 41 is connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com