Door trim panel assembly having integrated soft-touch aesthetic feature and method of manufacturing same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

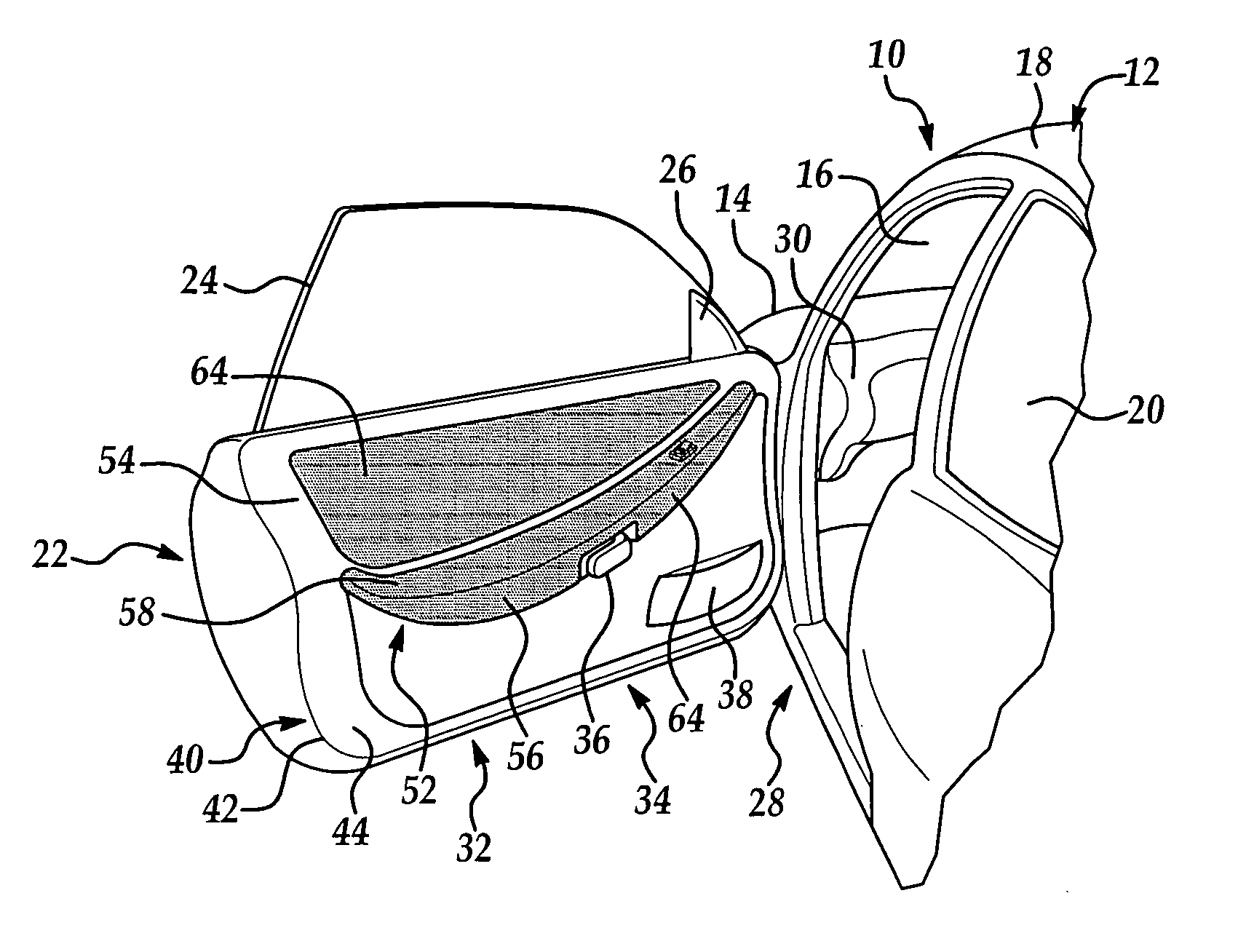

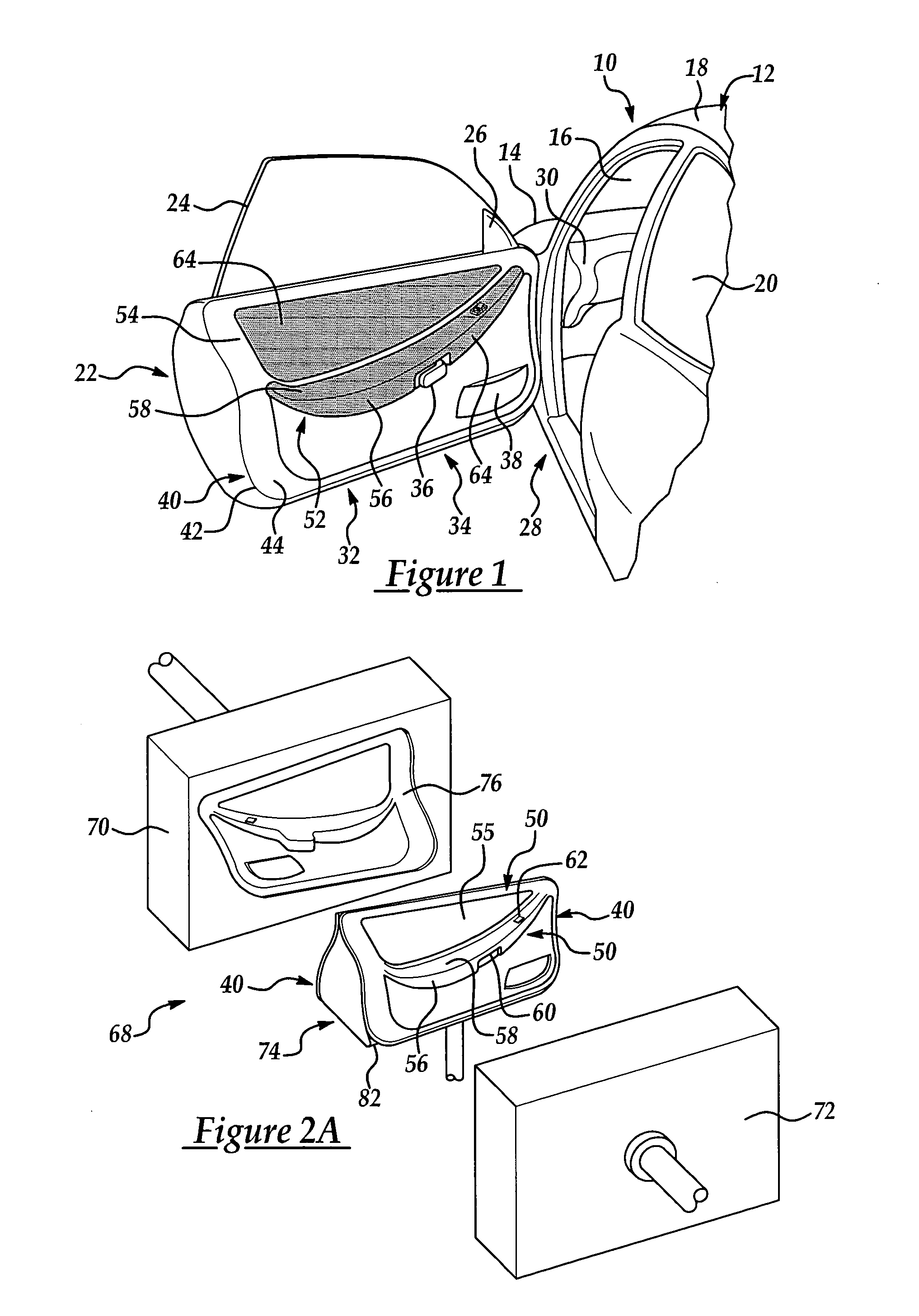

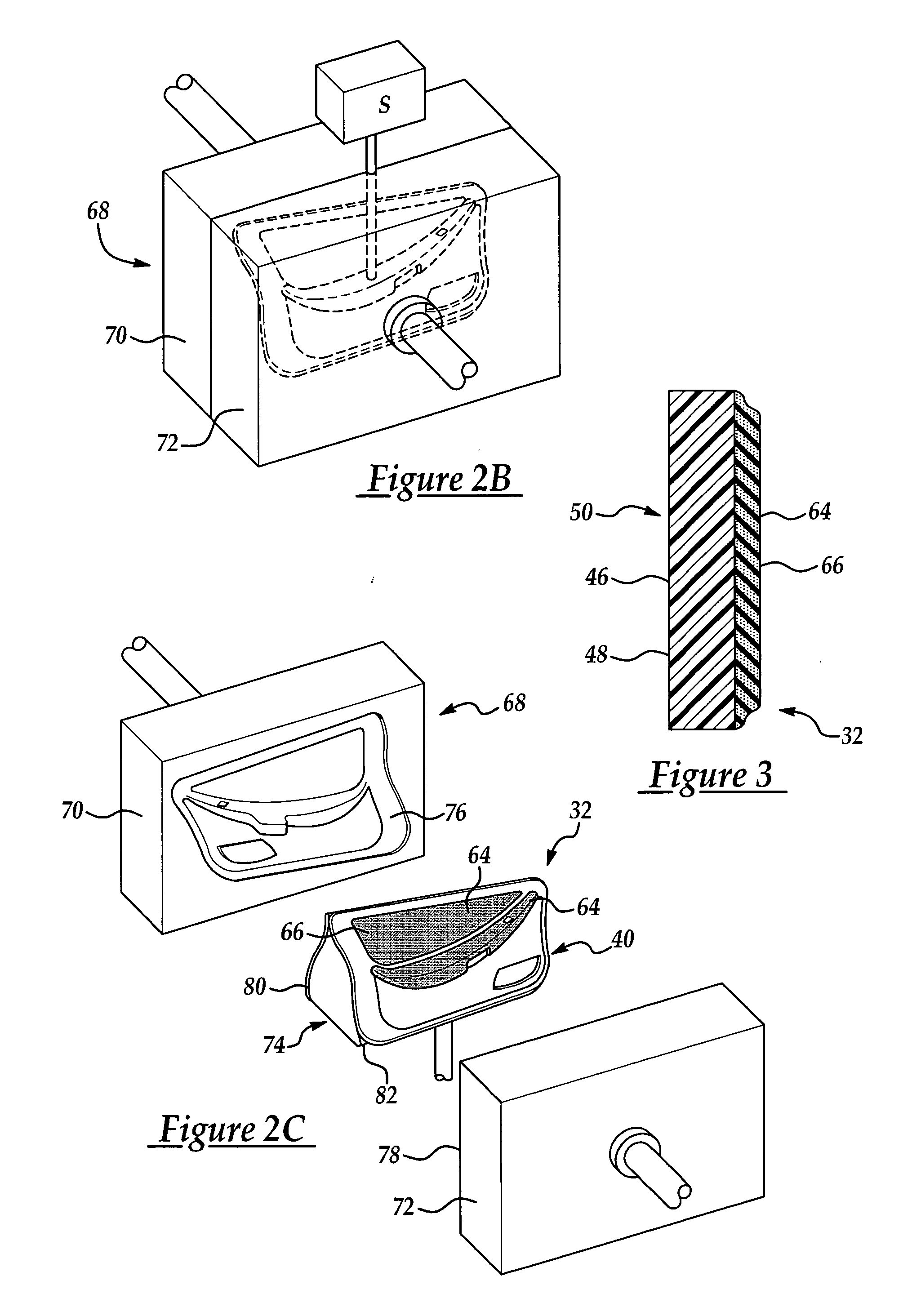

[0022] A vehicle that employs the door trim panel assembly of the present invention is generally indicated at 10 in FIG. 1, where like numbers are used to designate like structure throughout the figures. The vehicle 10 includes a vehicle body generally indicated at 12, having a hood 14, windshield 16, roof 18, and side window 20. The vehicle 10 further includes a vehicle door, generally indicated at 22. The vehicle door 22 is adapted to be pivotally mounted to the vehicle body 12 and includes components such as a window 24 and a side mirror panel 26 for covering the side rear view mirror mounts (not shown). The vehicle 10 further includes an interior generally indicated at 28. The interior 28 includes a plurality of trim panels, such as a dashboard 30, that provide an aesthetic and ergonomic environment for the vehicle occupant. However, those having ordinary skill in the art will appreciate that the interior 28 of a vehicle 10 includes components such as seats, a center console, st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

| Color | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com