Apparatus and method for containing and regulating the pressure in a pressure vessel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

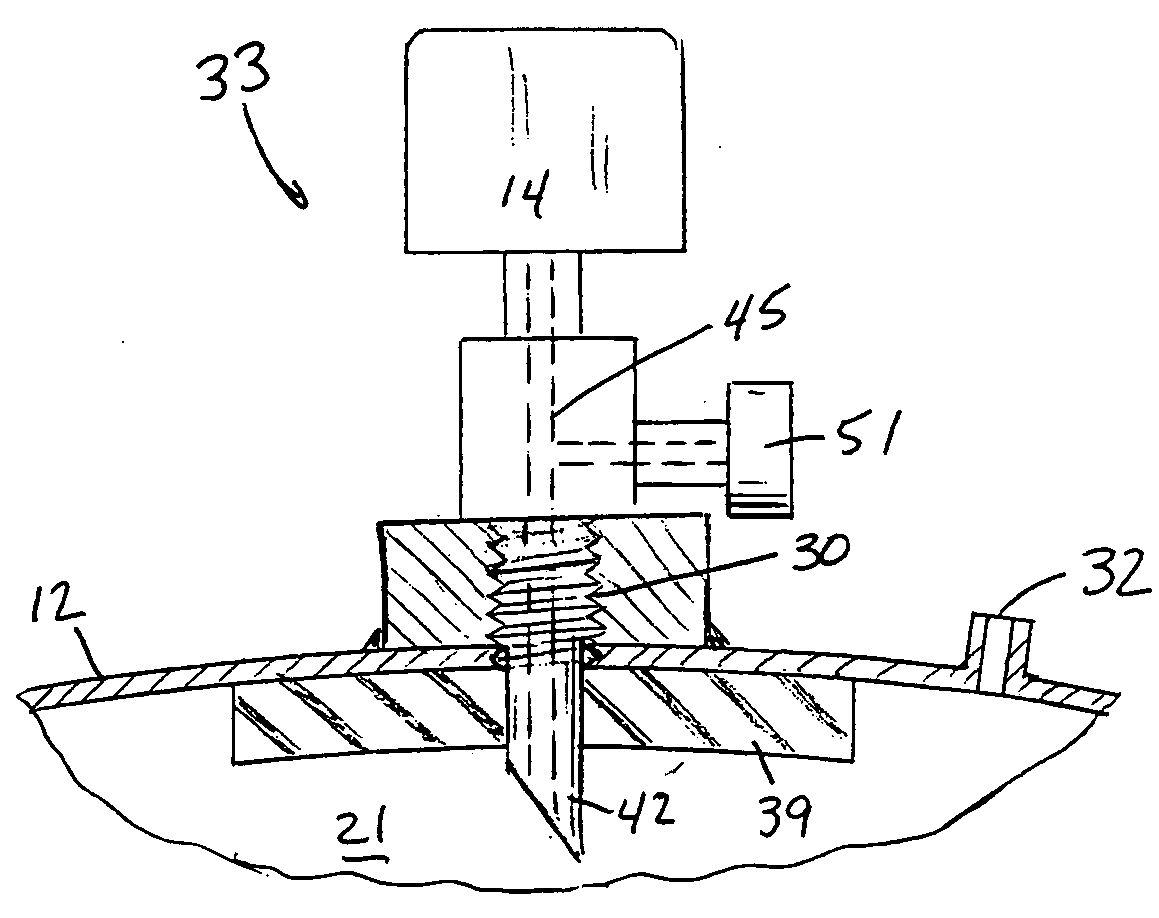

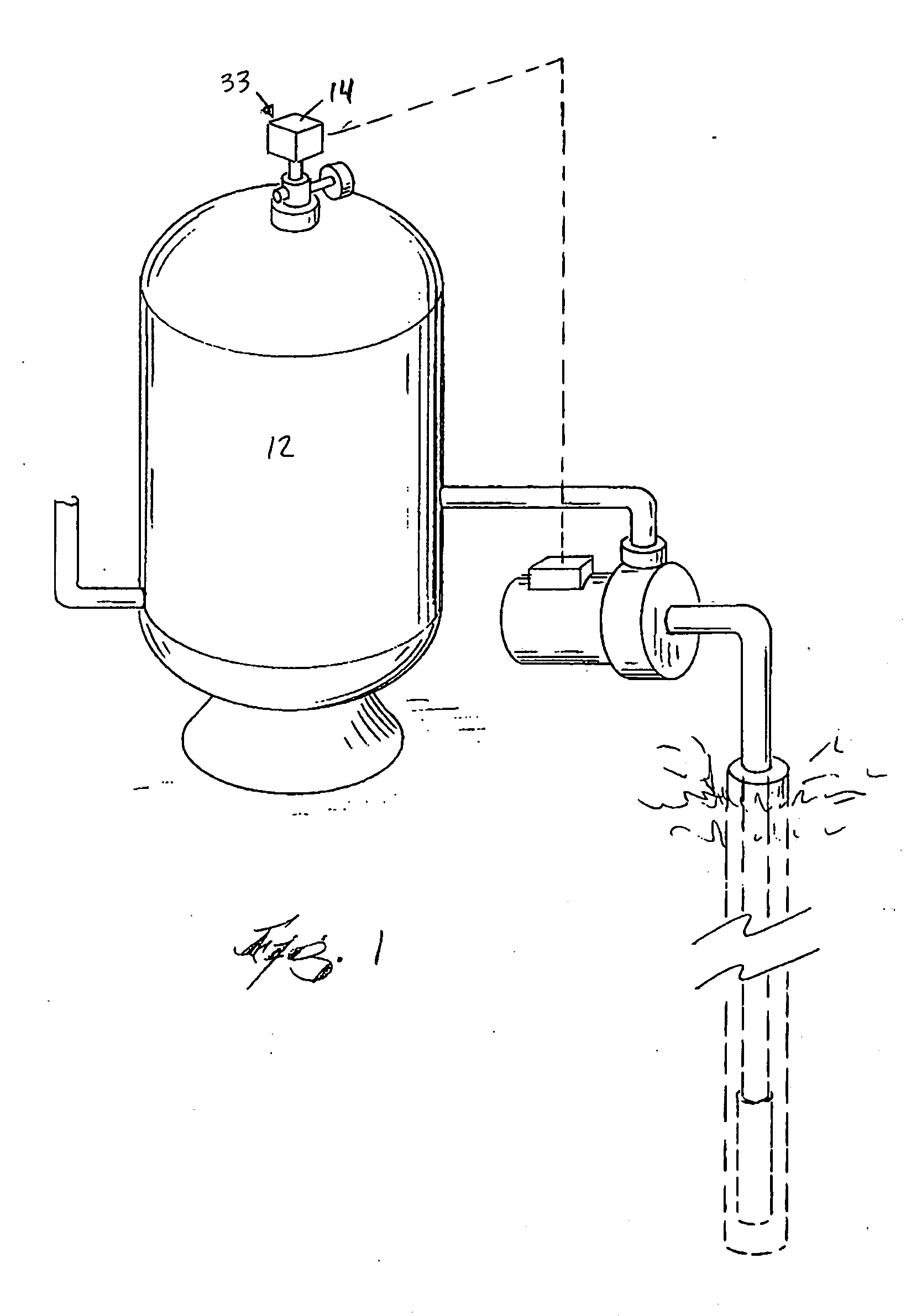

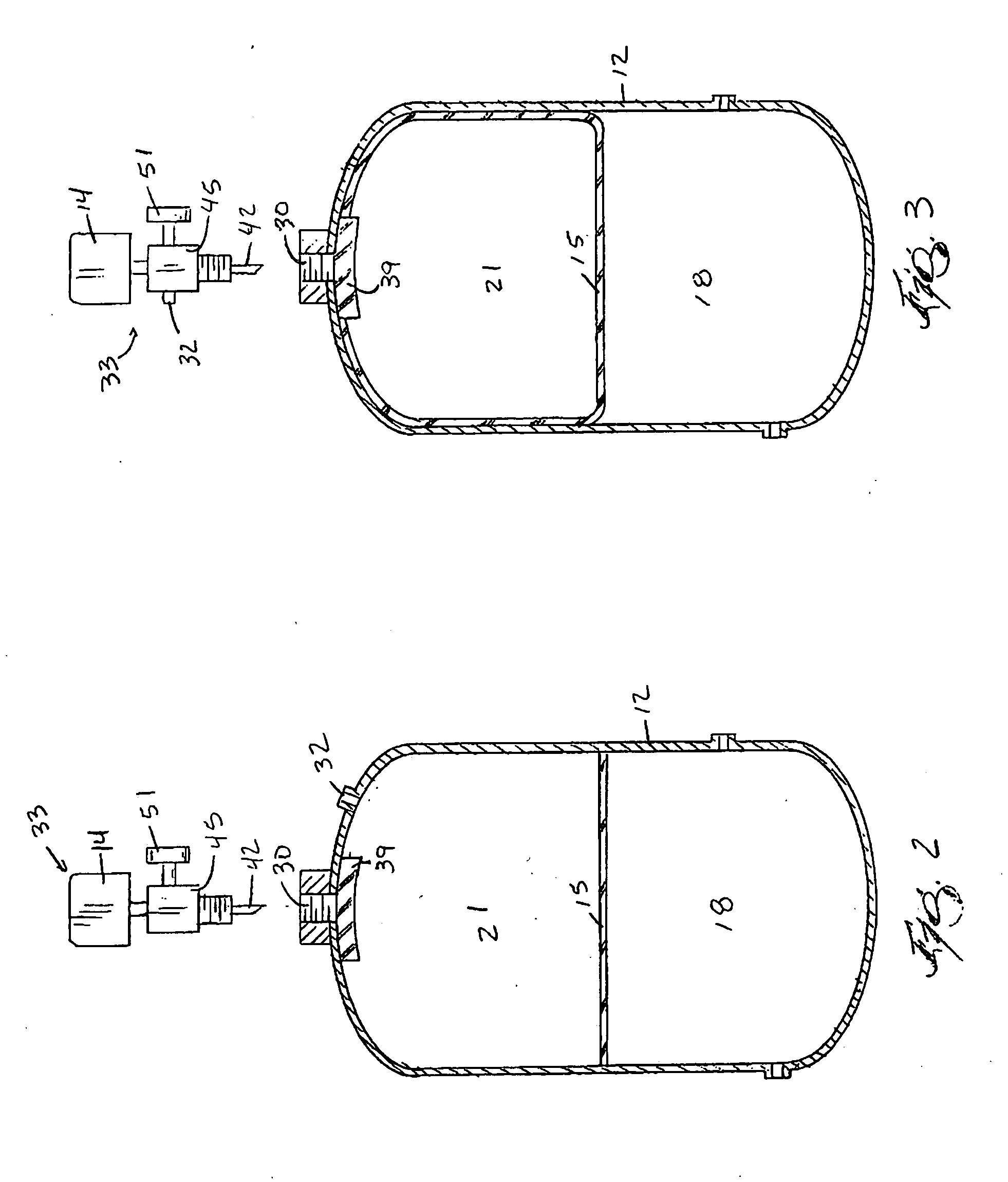

[0022] As illustrated in FIG. 1, a water pressure system for a well generally has a drop pipe extending into a water bearing aquifer, and a pump is used to deliver water from the aquifer to a pressure vessel or storage tank 12. Several types of pumps can be used, such as submersible pumps and non-submersible pumps. Water from the pressure tank 12 can be distributed from the tank for use.

[0023] The pressure tank 12 generally holds a reserve supply of water under pressure within the tank until it is needed. As water is drawn from the tank 12, the pressure within the tank 12 forces the water out of the tank 12 and consequently the pressure gradually decreases. A pressure switch 14 coupled to the tank 12 is used to maintain the pressure within the tank 12 between a preset minimum value and a preset maximum value. Upon reaching the preset minimum pressure, the pressure switch 14 automatically activates the pump. Water is then pumped into the tank 12 to replenish the tank 12 with water a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com