Storage battery automatic slot entering device

A battery, automatic technology, applied in the direction of lead-acid battery, lead-acid battery construction, sustainable manufacturing/processing, etc., can solve the problem of being vulnerable to occupational health damage by lead dust, eliminate hidden safety and quality risks, and improve production efficiency , the effect of removing physical labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

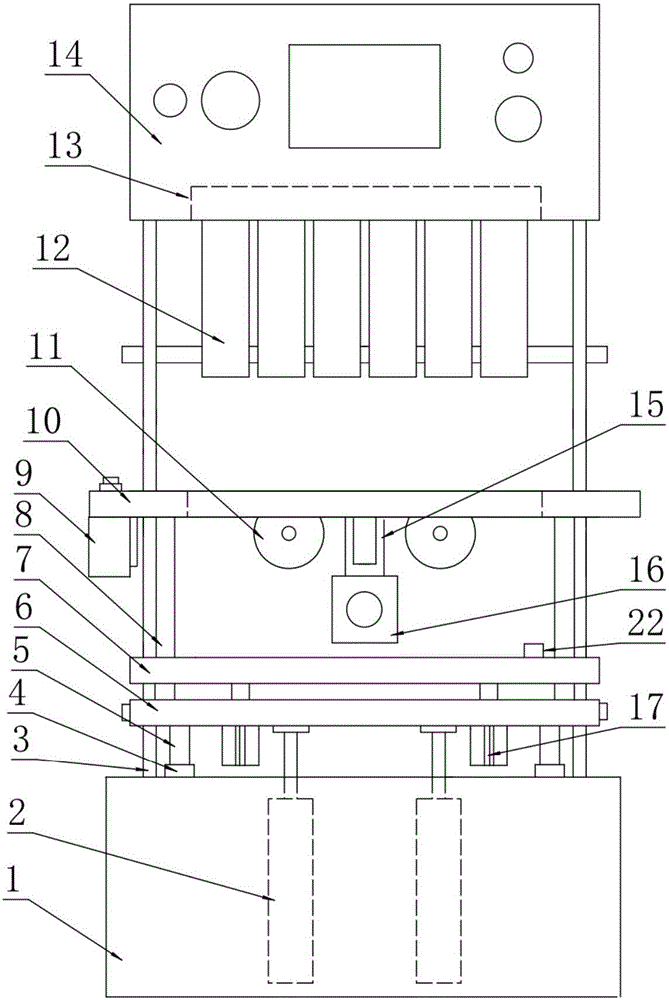

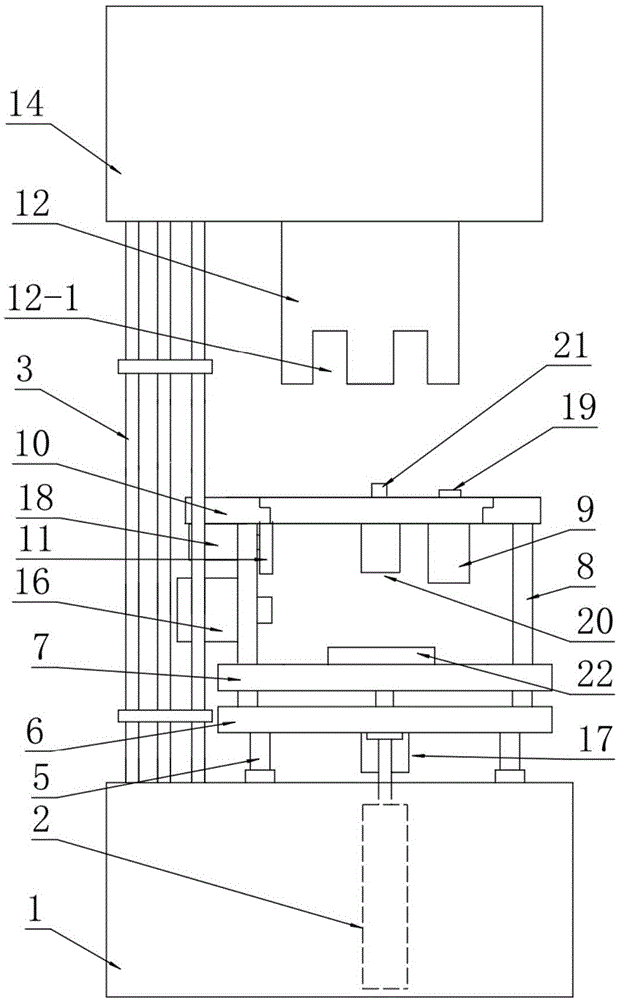

[0018] see figure 1 , figure 2 , the present invention includes a base 1 , a slot-entry elevating mechanism, a battery shell elevating mechanism, an electrode group clamp support frame 10 , a machine head 14 and an electrode group press-fitting module 13 . The base is the support part of the device, and a row of uprights are respectively fixed on both sides of the base, and the top of the uprights 3 fixes the machine head. The pole group press-fit module 12 is fixed to the machine head through the connecting plate 13. The upper part of the pole group press-fit module is a whole, and the lower part is six independent modules side by side. There is a gap between adjacent independent modules, and the gap is used to press the pole group. Each independent module enters each single cell of the battery case respectively. The bottom of each independent module is provided with two grooves, and the groove 12-1 is used to give way to the upper pole of the pole group.

[0019] still r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com