A kind of high stability construction machinery slotting equipment

A technology for construction machinery and slotting equipment, which is applied to stone processing equipment, work accessories, manufacturing tools, etc., can solve problems such as overheating, replacement of blades, and high cost, so as to increase the flow rate, reduce the flow area, and reduce the The effect of opening the area on the groove

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

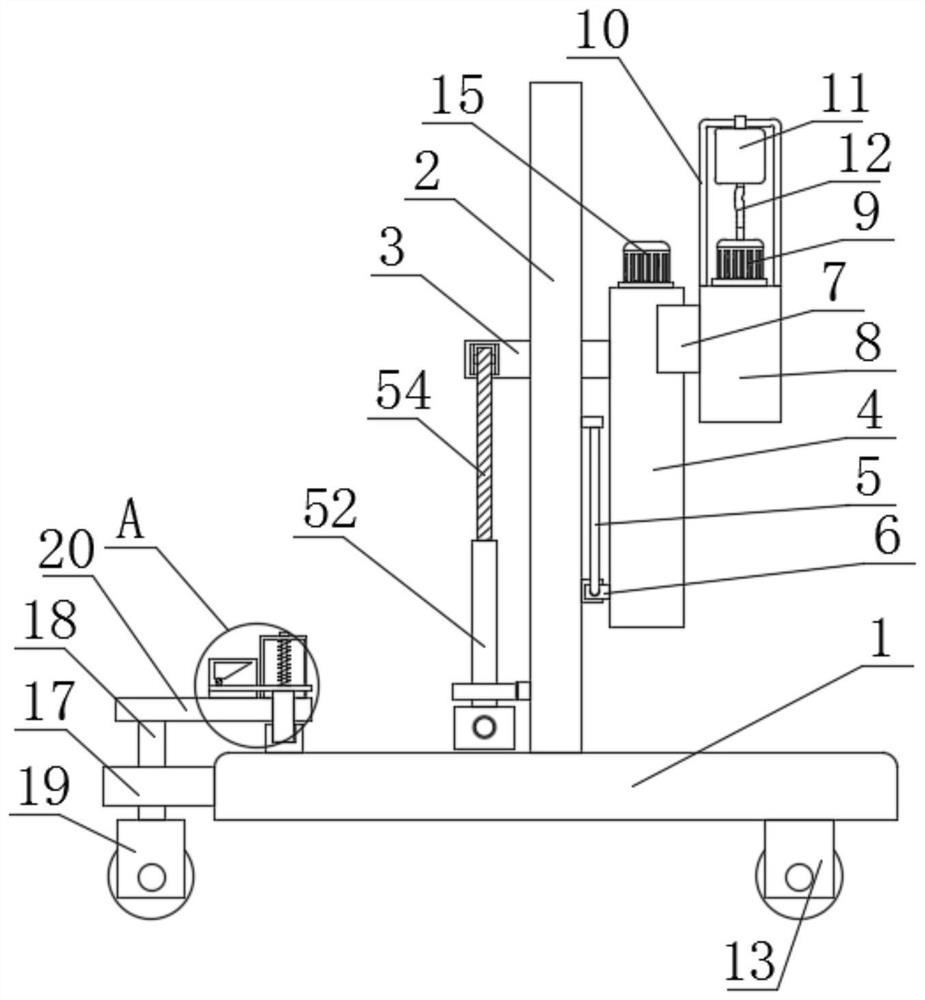

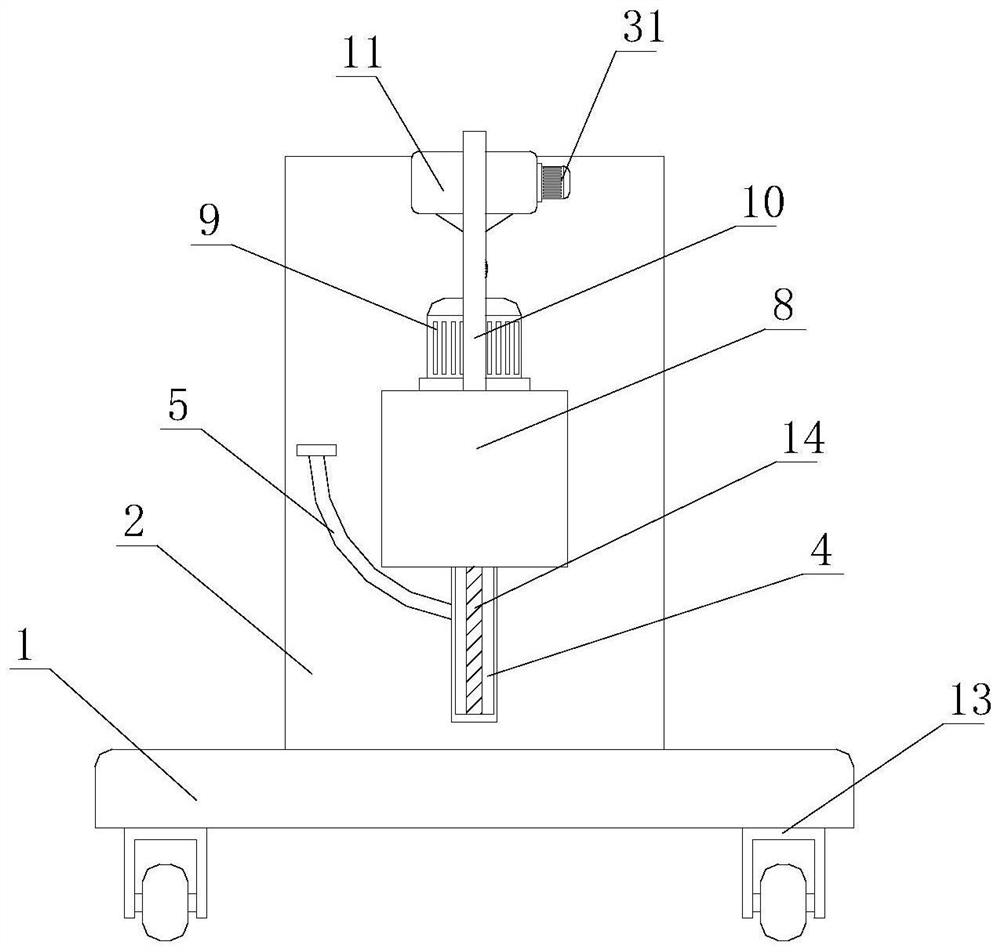

[0044] Example 1: as Figure 1-9 As shown, a high-stability construction machinery slotting equipment includes a base 1, a support plate 2 is fixedly installed on the top of the base 1, a support shaft 3 is rotatably connected to the support plate 2, and a drive assembly is fixedly installed at one end of the support shaft 3 , and the drive assembly is fixedly installed with a slotted assembly, the base 1 is provided with a through hole 30, the slotted assembly corresponds to the through hole 30, the bottom side of the base 1 is symmetrically fixed with two support wheels 13, and the base 1 A steering wheel 19 is rotatably connected to one side of the base 1, a drive motor 48 is fixedly installed on the top of the base 1, and a threaded cover 52 is drivingly connected to the output shaft of the driving motor 48. The cover 52 is internally threaded with a linkage screw 54 , the top end of the linkage screw 54 extends to the top of the screw cover 52 and is rotatably connected w...

Embodiment 2

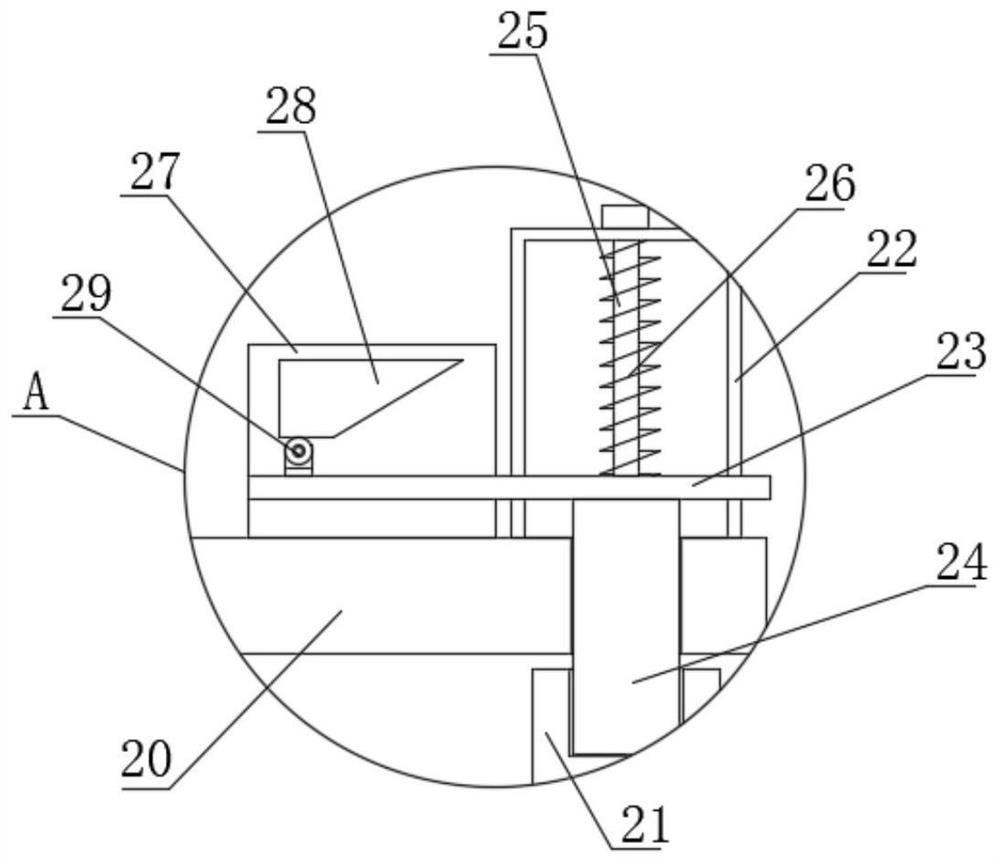

[0055] Embodiment 2: as Figure 10-15 As shown, a high-stability construction machinery slotting equipment, the difference between this embodiment and the first embodiment is that a connecting plate 17 is fixedly installed on one side of the base 1, and a rotating shaft 18 is rotatably connected to the connecting plate 17. The bottom end is fixedly connected with the steering wheel 19, the top end of the rotating shaft 18 is fixedly installed with a fixed plate 20, the top side of the fixed plate 20 is fixedly installed with a moving frame 22, and the moving frame 22 is slidably connected with a moving plate 23. A reset rod 25 is fixedly installed on the top, and the top of the reset rod 25 penetrates the movable frame 22 and extends to the top of the movable frame 22. The reset rod 25 is sleeved with a reset spring 26 located in the movable frame 22, and the top of the reset spring 26 and the bottom end are respectively fixedly connected with the top inner wall of the moving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com