Rapid grooving equipment for indoor ground wire duct

A technology for indoor floor and grooving equipment, applied in stone processing equipment, work accessories, manufacturing tools, etc., can solve problems such as affecting the grooving effect, high work intensity, damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

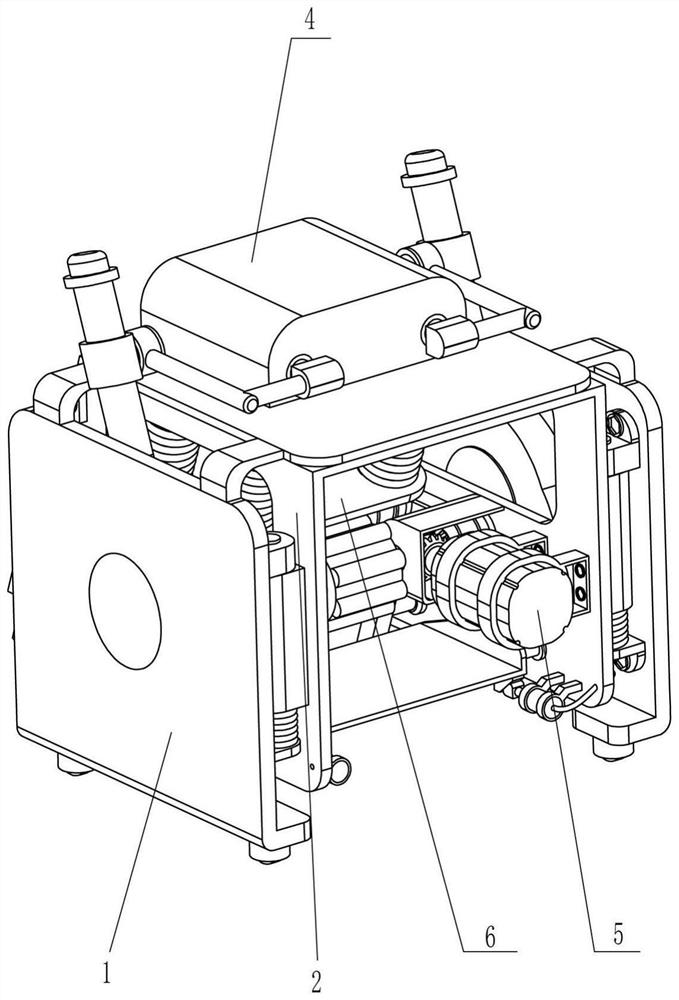

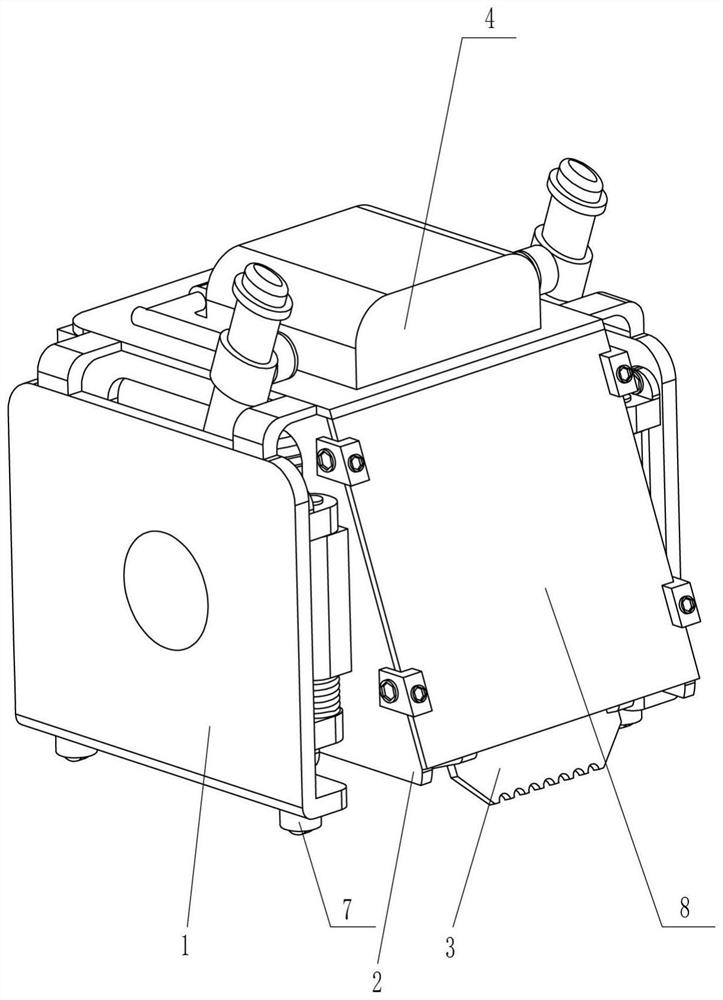

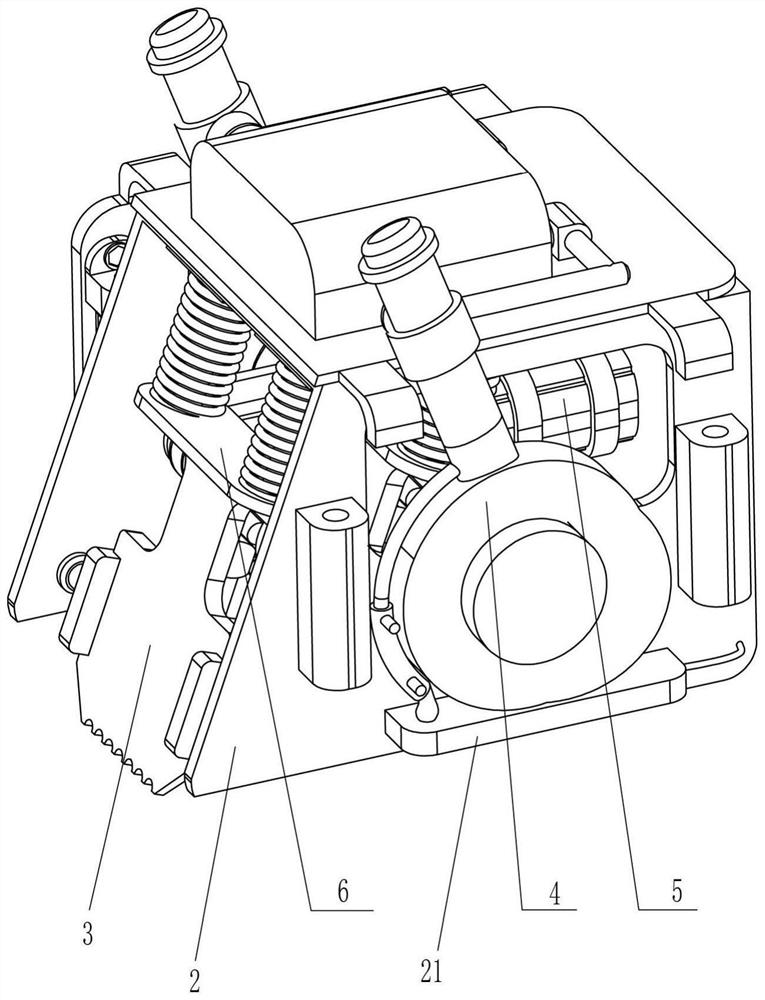

[0032] A kind of fast slotting equipment for indoor ground trunking, such as figure 1 , figure 2 , image 3 with Image 6 As shown, it includes a first fixed frame 1, a fixed frame 2, a hollow plate 21, a slotting knife 3, a guide block 31, a driving mechanism 5 and a sliding mechanism 6, and the first fixed frame 1 is slidingly provided with a fixed frame 2, Both sides of the lower part of the fixed frame 2 are provided with hollow plates 21, the inner wall of the lower part of the fixed frame 2 is provided with two guide blocks 31 on both sides, and the two guide blocks 31 on the same vertical side are slidingly installed with slots. Knife 3, the lower part of the slotting knife 3 is wave-shaped, which reduces the impact force while ensuring the quality of slotting. The slotting knife 3 moves up and down to slot the ground. The slotting knife 3 is located on the left side of the fixed frame 2, and the fixed frame 2 The inner right side is provided with a driving mechanis...

Embodiment 2

[0037] On the basis of Example 1, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 7 with Figure 8 As shown, it also includes a lifting mechanism 4, which can drive the fixed frame 2 and the slotting knife 3 to move up and down to adjust the slotting height. 44, guide bar 45 and the first spring 46, first fixed mount 1 top is provided with cylinder 41, and the driving rod right side of cylinder 41 is connected with pushing frame 42 symmetrically front and rear, first fixed mount 1 inner wall front and rear both sides are all rotationally designed. Hinged cam 43 is arranged, and hinged cam 43 is in contact with hollow plate 21, and the periphery of hinged cam 43 is connected with swing rod 44, and swing rod 44 is all slidably connected with push frame 42 on the same side. Left and right symmetrical bolts are connected with guide rods 45 , and the guide rods 45 are all slidably connected to the outside of the fixed frame 2 , and a first spring 46 ...

Embodiment 3

[0041] On the basis of Example 2, such as figure 2 , Figure 9 with Figure 10 As shown, it also includes a moving device 8, which drives the entire slotting equipment to move easily. The moving device 8 includes a fixed ring 81, a hinged rod 82 and a moving wheel 83. The left and right sides of the bottom of the first fixed frame 1 are all symmetrical A fixed ring 81 is provided, and hinged rods 82 are hinged in the fixed rings 81, and movable wheels 83 are arranged on the hinged rods 82.

[0042] Also include protective device 9, protective device 9 can prevent stones from splashing and hurting personnel, protective device 9 includes second fixed block 91, protective plate 92 and fixed screw rod 93, the left side of both sides of fixed frame 2 front and back are all up and down symmetrically by fixing The second fixing block 91 is installed on the screw rod 93 , and the protective plate 92 is connected between the second fixing blocks 91 through the fixing screw rod 93 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com