A storage battery automatic slotting device

A battery, automatic technology, applied in the direction of lead-acid battery, lead-acid battery construction, sustainable manufacturing/processing, etc., can solve problems such as being susceptible to occupational health injuries from lead dust, eliminate hidden safety and quality risks, and relieve physical labor. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

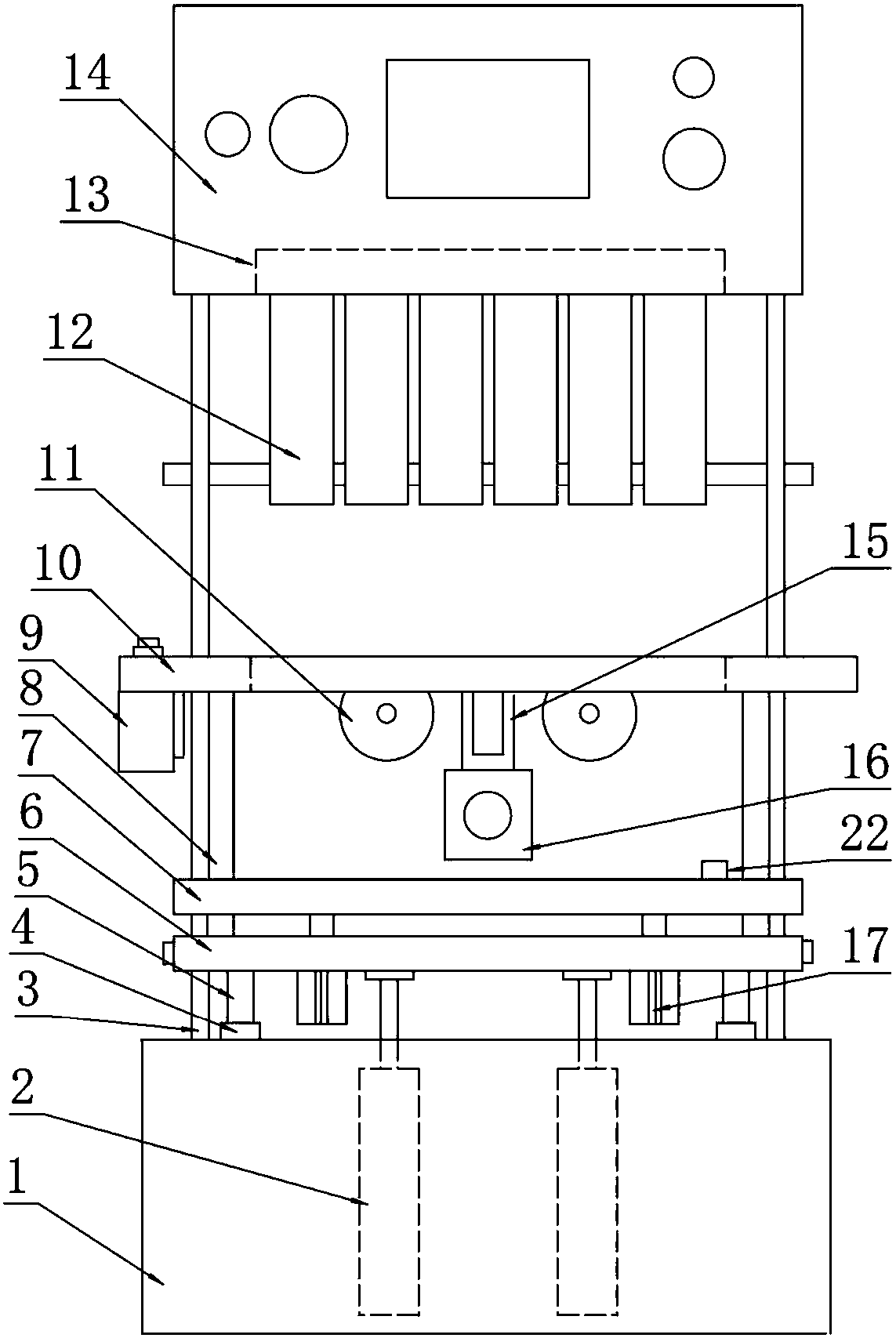

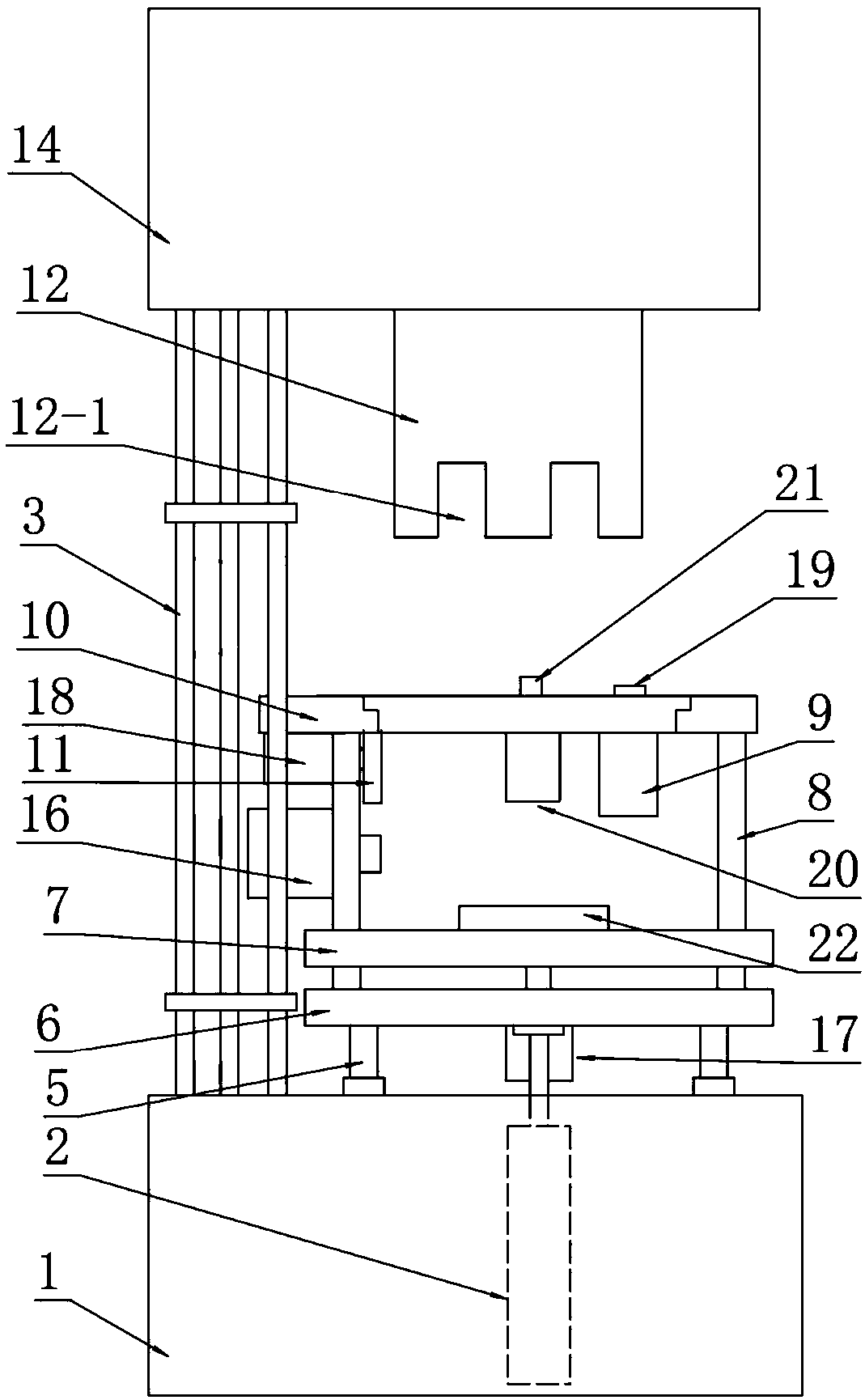

[0018] See figure 1 , figure 2 , The present invention includes a base 1, a slot-in lifting mechanism, a battery case lifting mechanism, a pole group clamp support frame 10, a handpiece 14 and a pole group pressing module 13. The base is the supporting part of the device. A row of columns are fixed on both sides of the base, and the upper part of the column 3 is fixed with the machine head. The pole group press-fitting module 12 is fixed to the machine head by the connecting plate 13. The upper part of the pole-group press-fitting module is a whole and the lower part is six independent modules side by side. There is a gap between adjacent independent modules, which is used to press the pole group When each independent module enters each cell of the battery case. Two grooves are provided at the bottom of each independent module, and the groove 12-1 is used to make way for the poles on the upper part of the pole group.

[0019] Still see figure 1 , figure 2 , The slot-in lifti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com