Machine for manufacturing stripe decorative plate for home decoration

A decorative board and stripe technology, applied in metal processing and other directions, can solve the problems of low work efficiency, time-consuming and laborious, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] A striped decorative panel manufacturing machine for home improvement such as Figure 1-3 As shown, it includes a bottom plate 1, a support block 2, a placement component 3 and a decorative strip slotting mechanism 4, a support block 2 is provided on the right side of the bottom plate 1, a placement component 3 is provided on the right side of the bottom plate 1, and a decorative strip is provided on the bottom plate 1 Slotting mechanism4.

[0067] Placement assembly 3 includes support feet 30, mounting plate 31, bracket 32 and baffle plate 33, two support feet 30 are provided on the right side of base plate 1, mounting plate 31 is provided on the right side of base plate 1, baffle plate 33 is provided on the top of support foot 30, A bracket 32 is provided between the top of the mounting plate 31 and the baffle plate 33 .

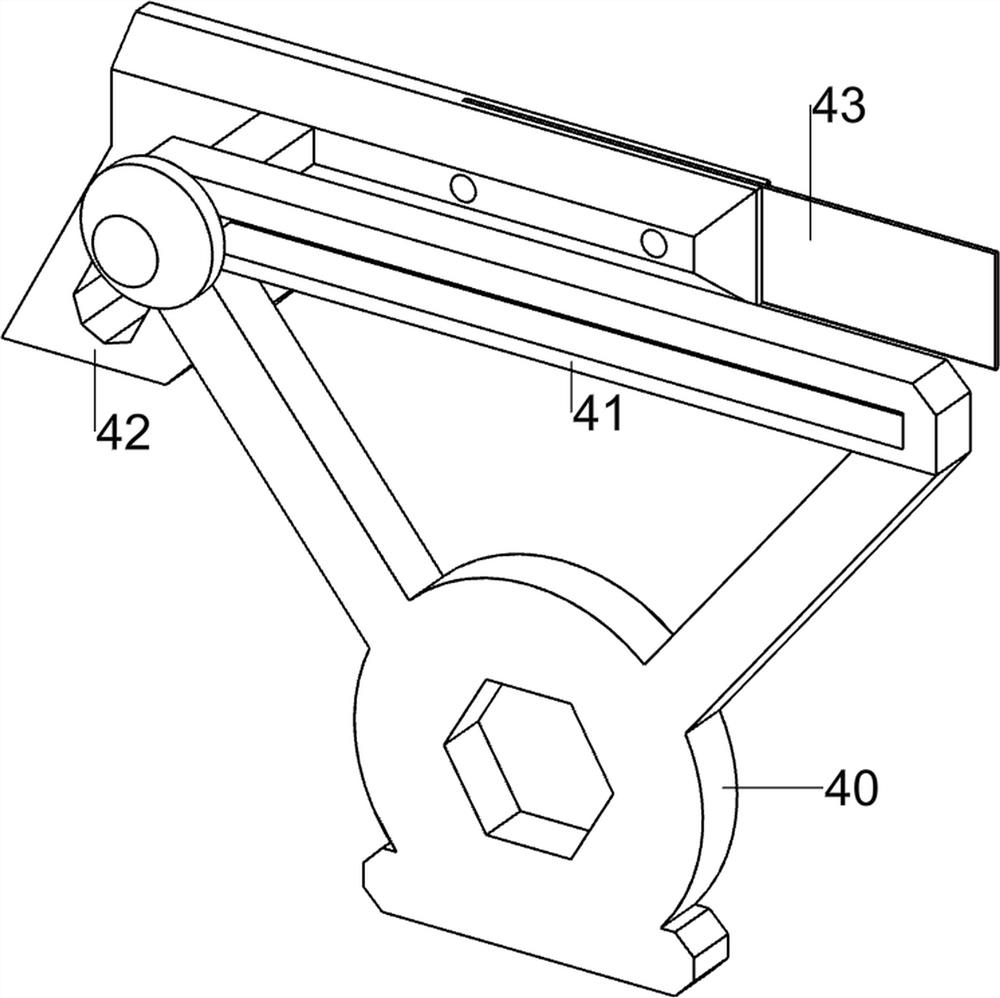

[0068] Decorative strip slotting mechanism 4 includes support plate 40, first slide rail 41, forward block 42 and slotting blade 43, base plat...

Embodiment 2

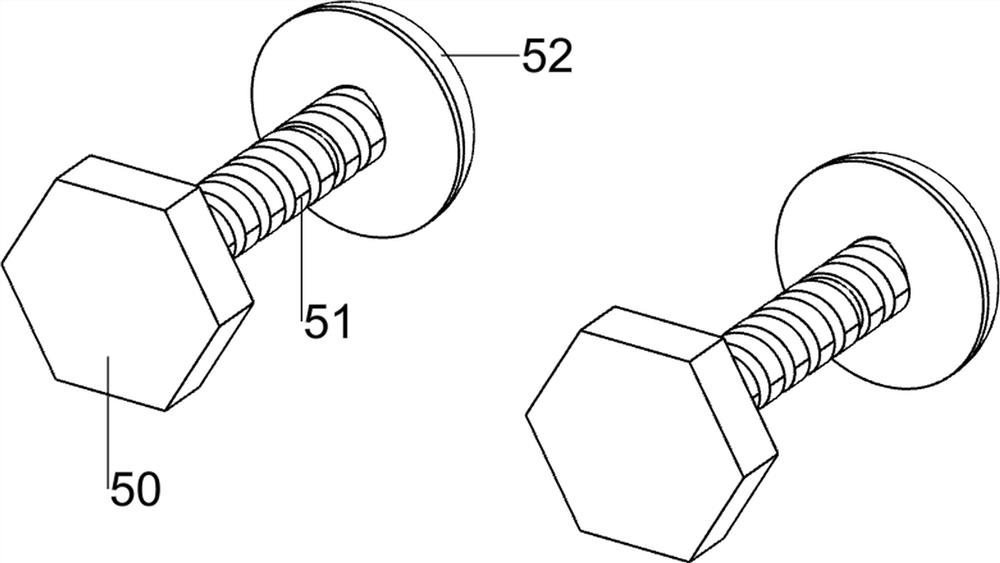

[0071] On the basis of Example 1, such as Figure 4-8 As shown, the blade replacement assembly 5 is also included. The blade replacement assembly 5 includes a hexagonal block 50, a screw 51 and a mounting plate 52. The slotting blade 43 is detachable, and the thread between the right side of the advancing block 42 and the slotting blade 43 There are two screw rods 51 connected in the same way, and the front side of the screw rods 51 is provided with a hexagonal block 50, and the rear side of the screw rods 51 is connected with a mounting plate 52 in a threaded manner.

[0072]When needing to change the slotting blade 43, the screw rod 51 will be rotated so that the screw rod 51 and the mounting disc 52 are separated, the slotting blade 43 is taken off, and a new blade is put on, then the screw rod 51 and the mounting disc 52 are assembled together, and the slotting The blade 43 is fixed.

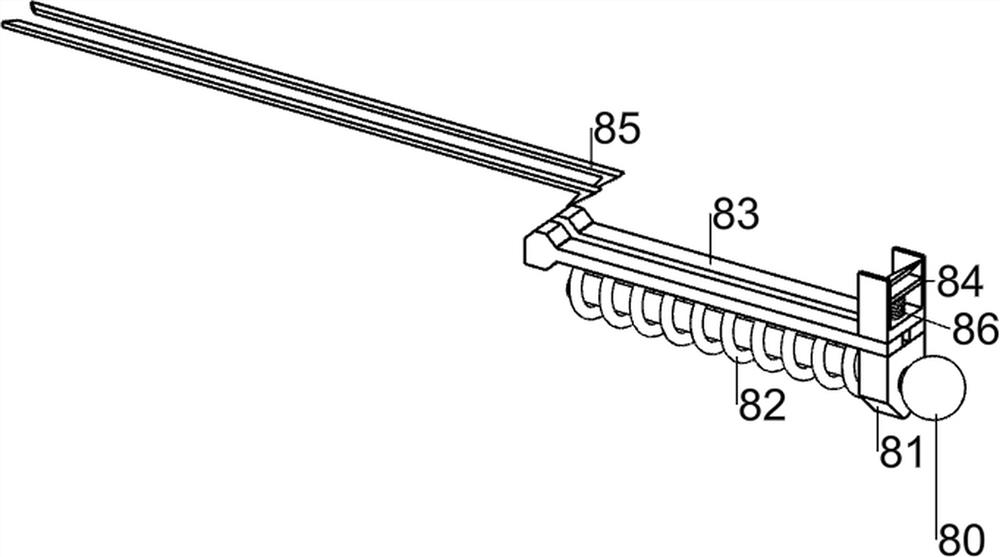

[0073] Also includes a reciprocating mechanism 6, the reciprocating mechanism 6 include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com