Tool starter head torsion releasing and onoff structure

A technology of screwdriver bits and tools, applied in the direction of manufacturing tools, wrenches, screwdrivers, etc., can solve the problems of destroying screw locking grooves, unable to meet screw locking requirements, poor locking effect, etc., and achieve the effect of rapid replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

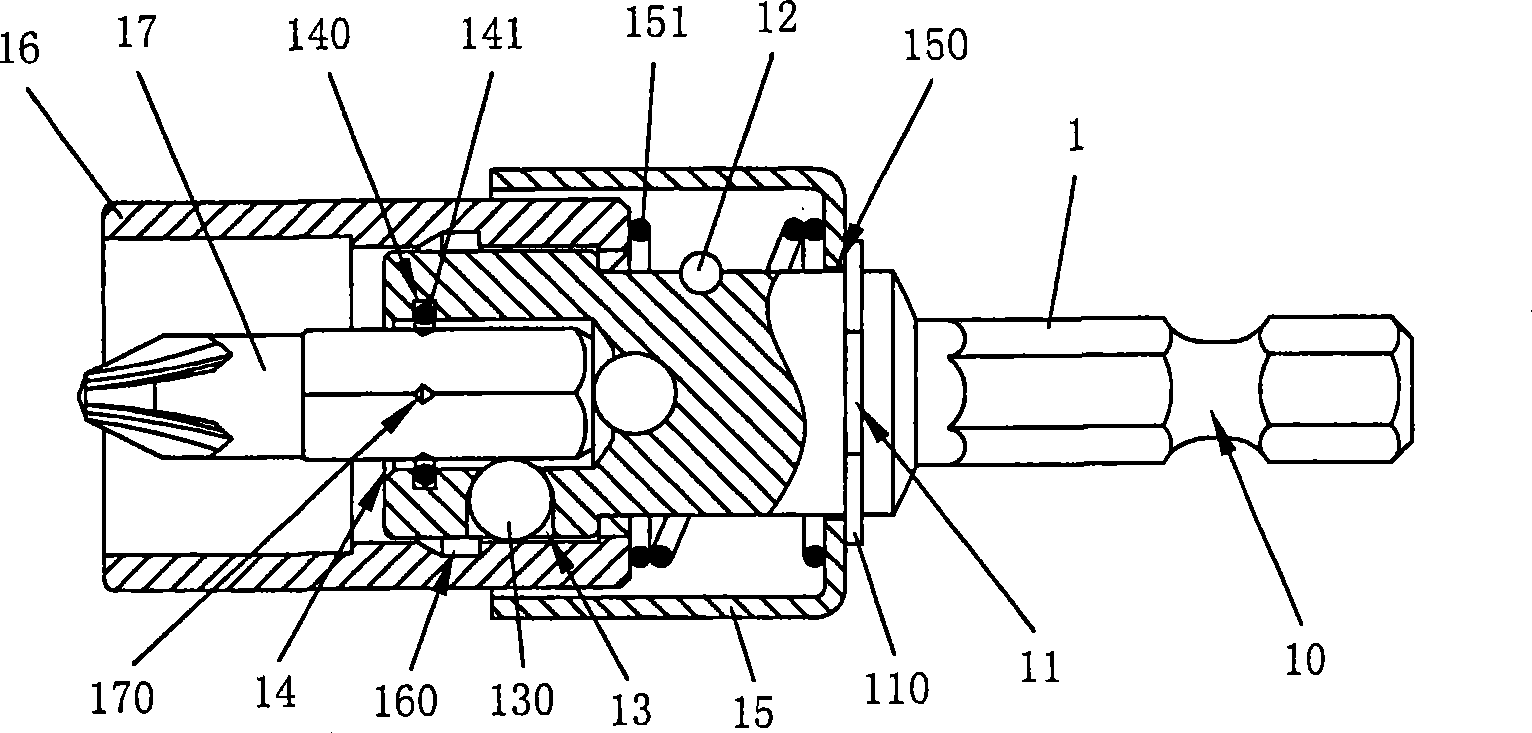

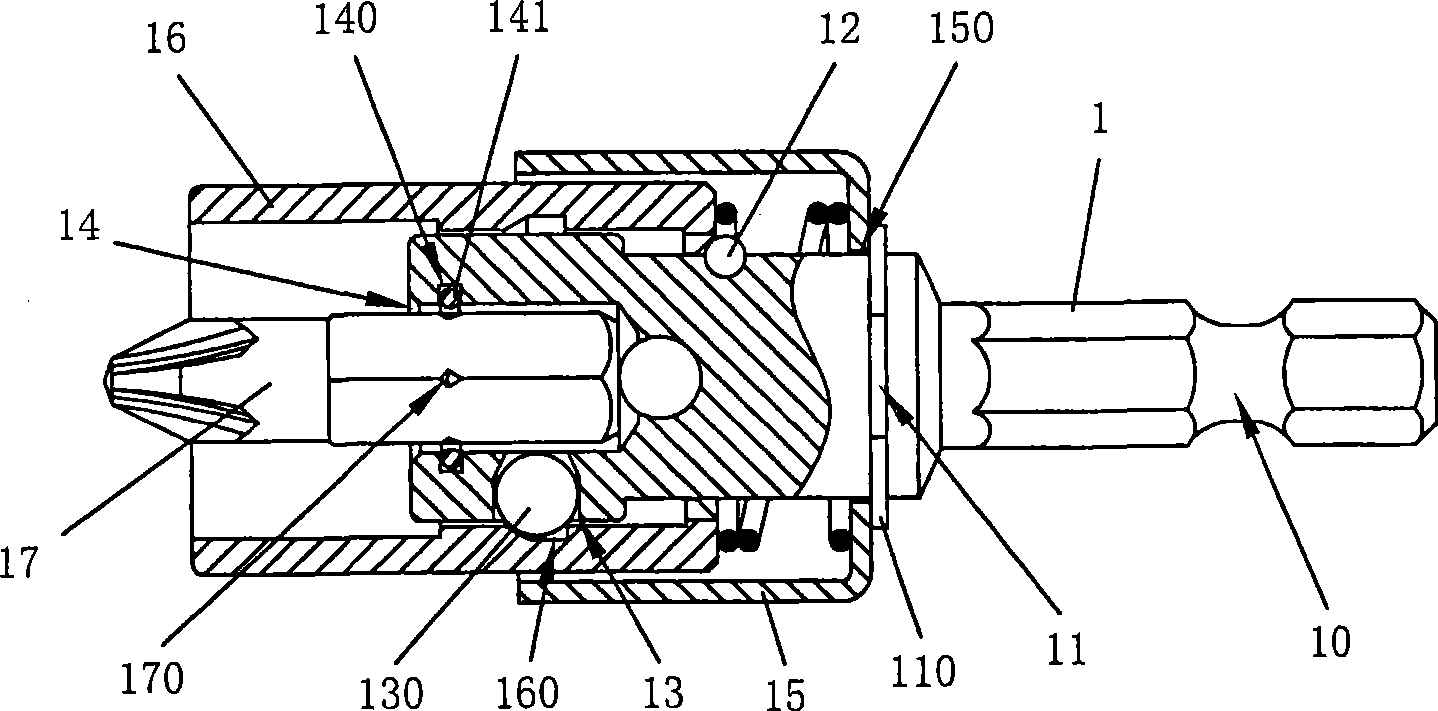

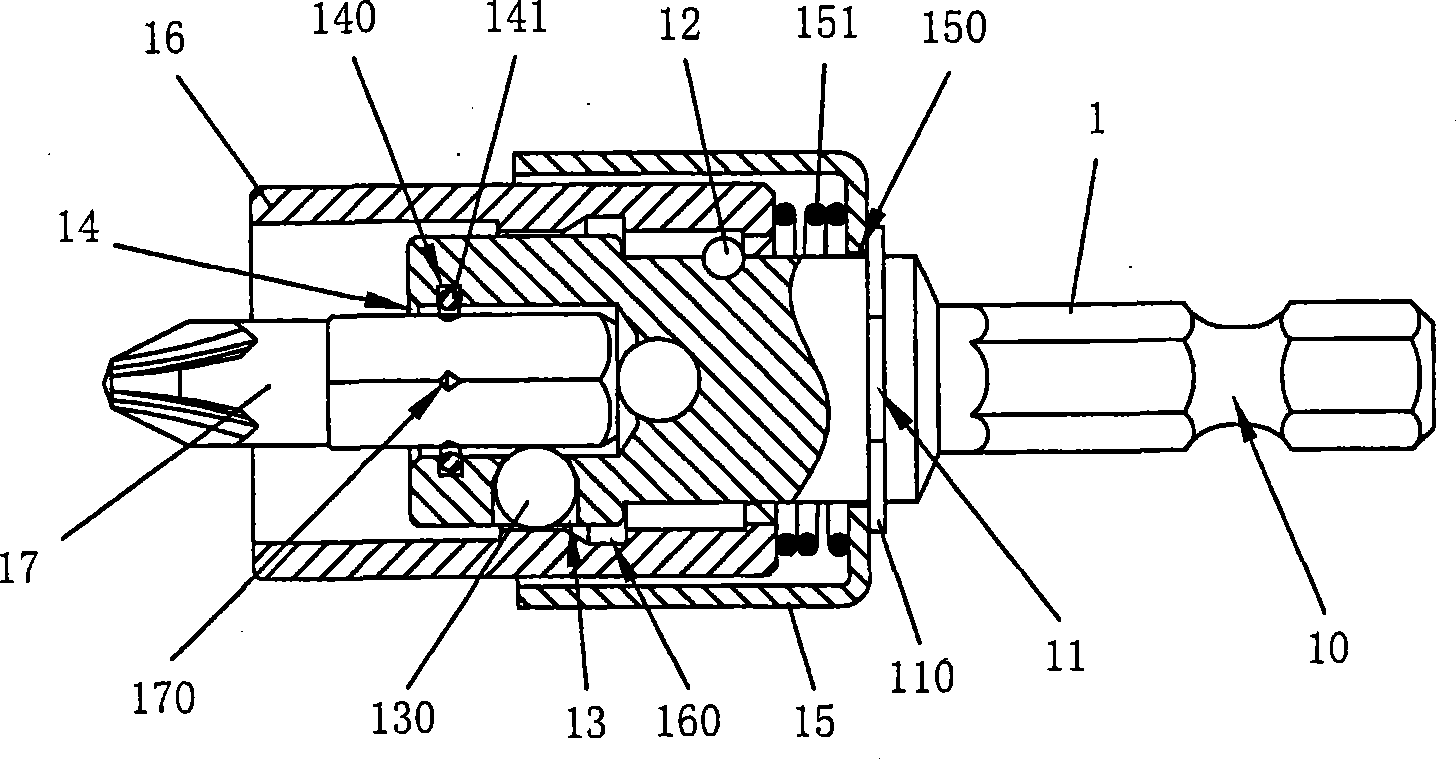

[0047] Such as Figure 4-14 As shown, it is Embodiment 1 of the torque release and clutch structure of the tool screwdriver head of the present invention. This Embodiment 1 includes:

[0048] The connecting rod body 2 is provided with a connecting rod part 20, which can be combined with various known hand tools or electric tools. And establish the E-type buckle groove 21, the E-type buckle 210 can be arranged in the E-type buckle groove 21, and set the washer 211 and the spring 212 on the side of the E-type buckle 210 (as shown in Figures 7-11), and use the washer 211 for the spring One side of 212 abuts against the top, limiting the receding distance of the outer ring 4 . An engaging flange 22 is also provided so that the aforementioned post body 2 has a reverse function. When the screw is pulled out using the reverse function of the post body 2, only the outer ring 4 needs to be compressed backward to keep the screwdriver head at its maximum outer diameter. The elongation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com