Sharp cooling and sharp heating highlight forming die

A forming mold and high heat technology, applied in the field of injection molding, can solve the problems of rapid heating and cooling of the mold, weld marks, flow marks and other problems, so as to improve the appearance quality of products, eliminate weld marks and flow marks, and improve surface gloss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

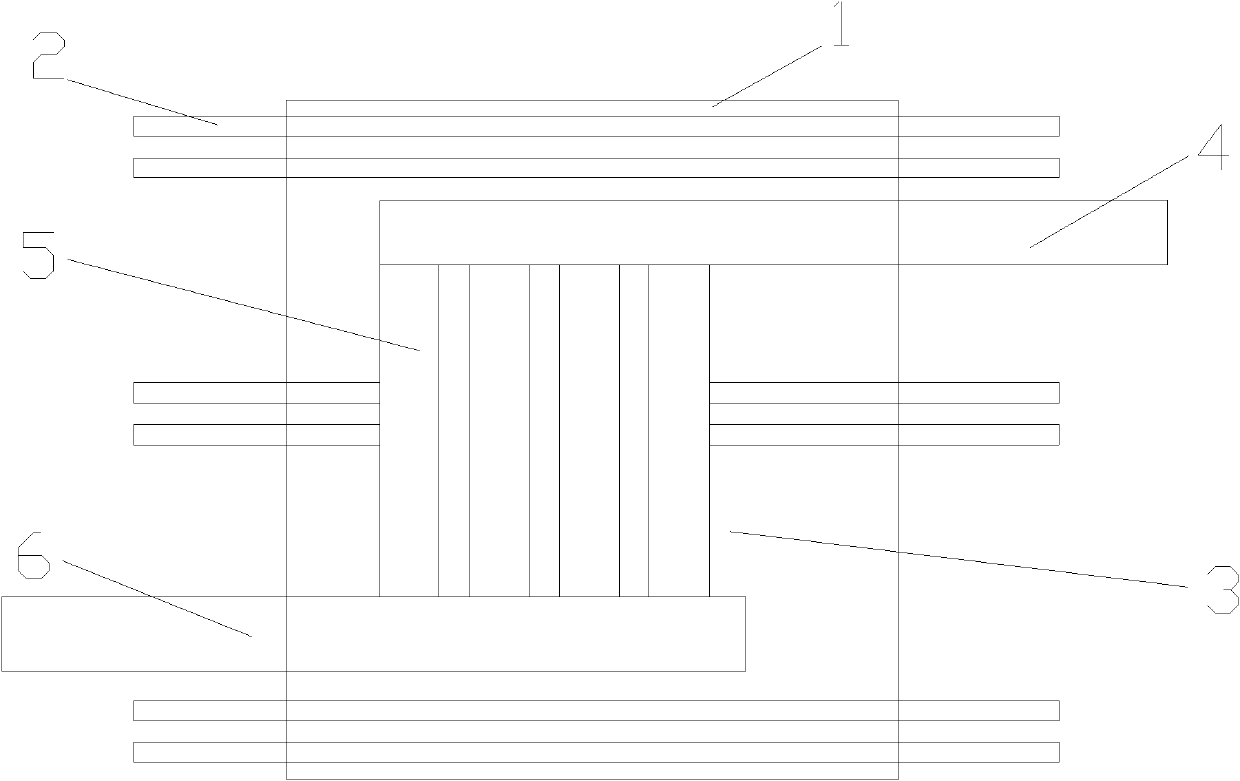

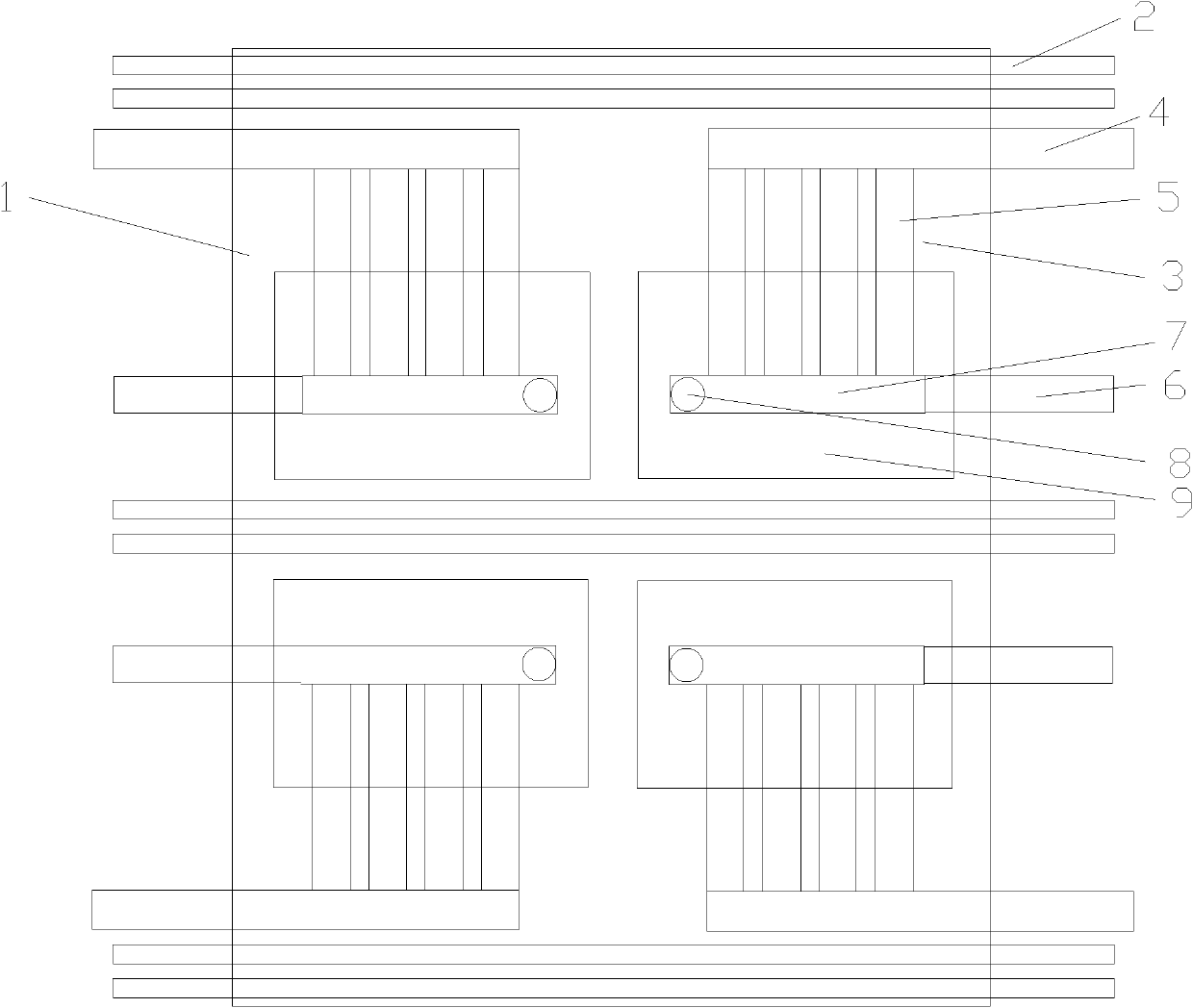

[0013] Such as figure 1 As shown, a rapidly cooling and rapidly heating high-gloss forming mold includes a female mold core 1, six cooling water channels 2 are arranged horizontally in the female mold core 1, and a steam pipeline 3 is also arranged in the female mold core 1. The steam pipeline 3 includes the air intake main pipe 4, the shunt pipe 5, and the air outlet main pipe 6. The upper right of the female mold core 1 extends into the air intake main pipe 4, and the air intake main pipe 4 extends inward to the middle of the female mold core 1, and is arranged side by side on the air intake main pipe 4. Connect four shunt pipes 5, four shunt pipes 5 extend downwards, a gas outlet main pipe 6 is connected at the tail of the four shunt pipes 5, the air outlet main pipe 6 is horizontally arranged and protrudes from the lower left side of the mother mold core 1. This s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com