Polyvinyl chloride composition for producing sheet material by rolling process

A technology of polyvinyl chloride and calendering, which is applied in the field of polyvinyl chloride compositions, can solve the problems of high price, cost, and high cost of impact modifiers, and achieve the effects of eliminating flow marks, saving costs, and excellent light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

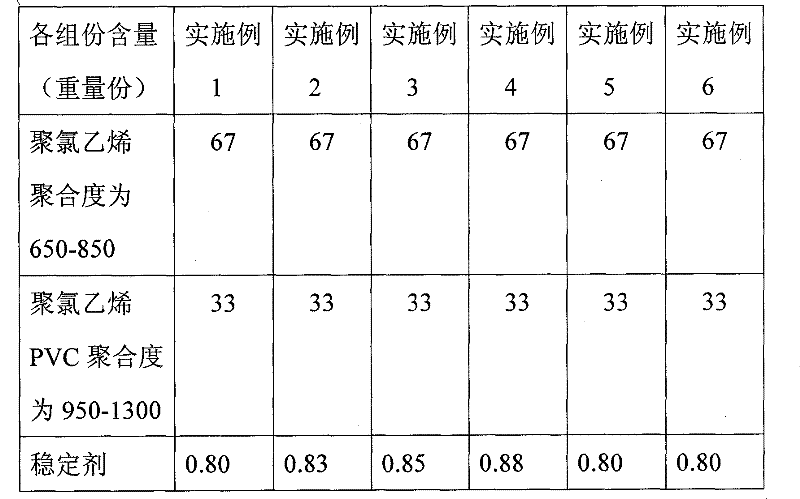

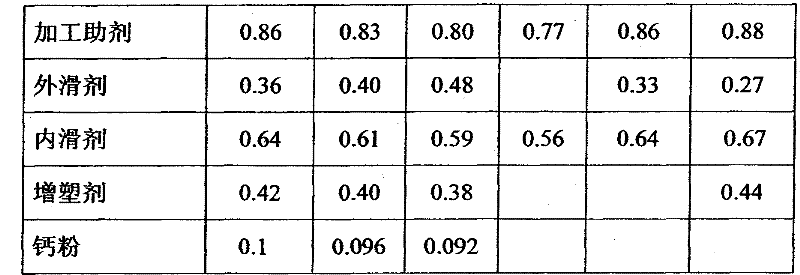

Embodiment 1

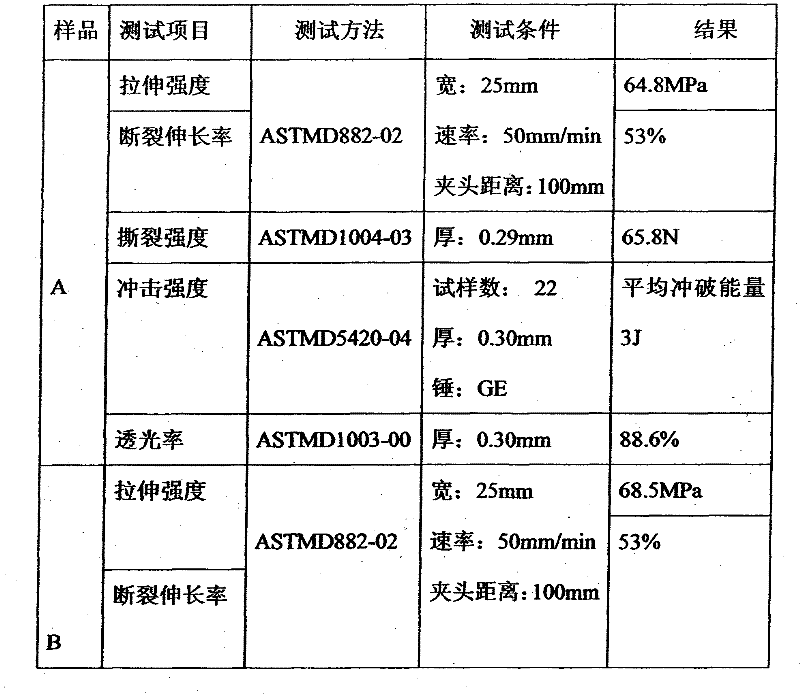

[0020] Take 67KG polyvinyl chloride with a polymerization degree of 650-850, mix with 33KG Dagu 1000 type or Beierhua 5 type polyvinyl chloride PVC with a polymerization degree of 1000, add 0.80KG TM-2080 stabilizer, add 0.86KG K-120P type processing aid, add 0.64KG AG-16 type internal slip agent, add 0.36KG AJ-70S type external slip agent, add 100G nano-scale calcium powder, add 0.19KG Mesamoll and 0.23KG LD -82 type plasticizer. Mix uniformly by general method, and make sheet with thickness of 0.35mm by calendering method.

Embodiment 2

[0022] Take 67KG polyvinyl chloride with a polymerization degree of 650-850, mix with 33KG Dagu 1000 type or Beierhua 5 type polyvinyl chloride PVC with a polymerization degree of 1000, add 0.83KG of TM-2080 stabilizer, add 0.83KG K-120P type processing aid, add 0.61KG AG-16 type internal slip agent, add 0.40KG AJ-70S type external slip agent, add 96G nano-scale calcium powder, add 0.18KG Mesamoll and 0.22KG LD -82 type plasticizer. Mix uniformly by general method, and make sheet with thickness of 0.30mm by calendering method.

Embodiment 3

[0024] Take two PVC powders of the same weight, add 0.85KG of TM-2080 type stabilizer, add 0.80KG of K-120P type processing aid, add 0.59KG of AG-16 type internal slip agent, add 0.48KG of AJ- 70S type slip agent, add 92G nano-scale calcium powder, add 0.17KG Mesamoll and 0.21KG LD-82 plasticizer. Mix uniformly by general method, and make sheet with thickness of 0.20mm by calendering method.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com