Flow mark-free processing mold and method for panel with polished surface

A technology for processing molds without flow marks, which can be used in household appliances, other household appliances, flat products, etc., and can solve the problems of the impact of the surface aesthetics of the formed panel and easy to be stolen.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

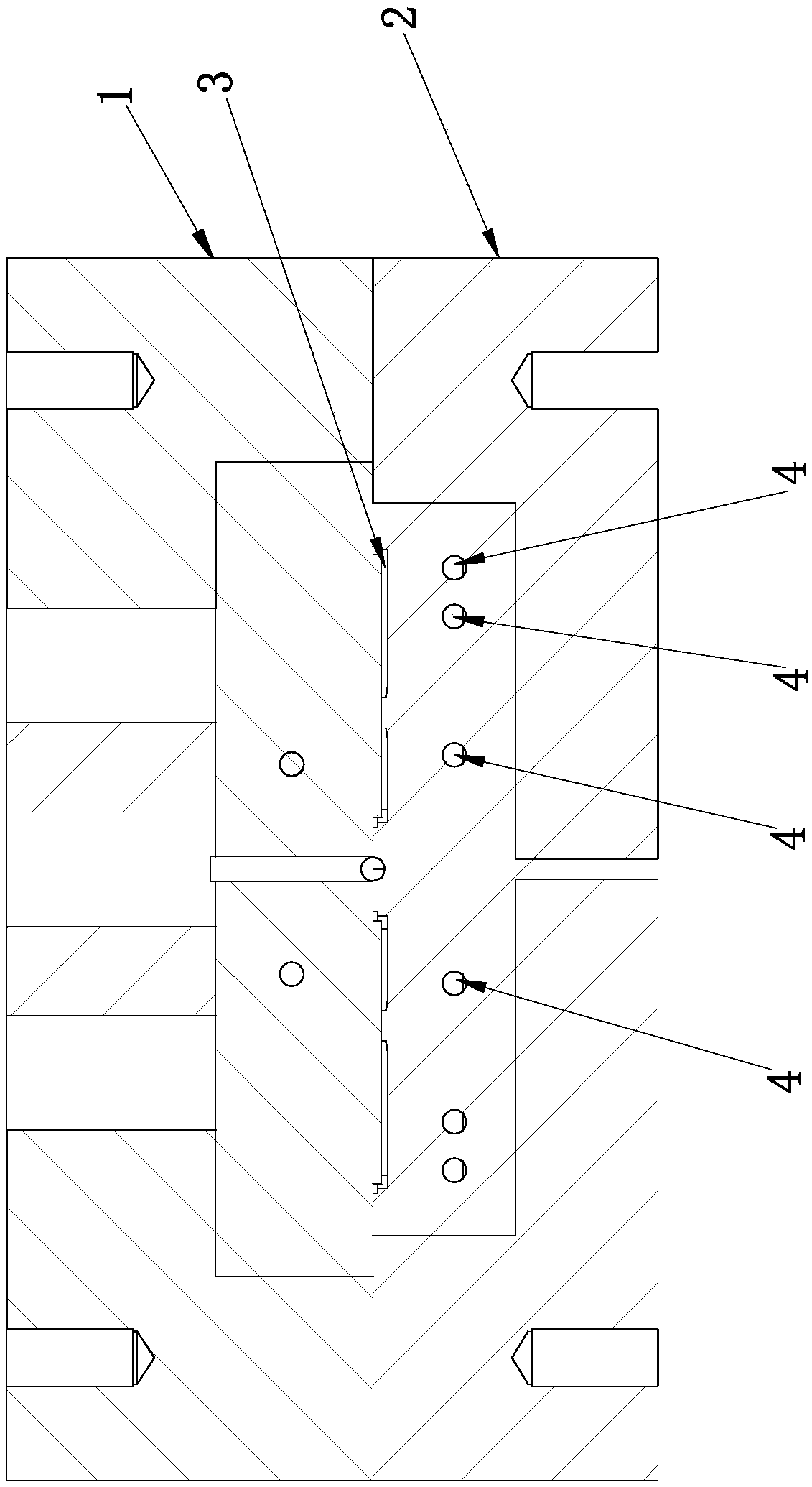

[0013] Such as figure 1 A non-flow mark processing mold for a polished surface treatment panel is shown, including an upper mold 1 and a lower mold 2 that can be fastened with the upper mold 1, and the upper mold 1 and the lower mold 2 are respectively provided with panels for forming The cavity is 3, and the upper mold 1 or the lower mold 2 is provided with a material inlet connected to the cavity, and the upper mold 1 has one end as the inlet end, and the other end is the output end and is isolated from the cavity 3 for heating medium The input heating channel 4 is located at the end of the panel where the liquid material enters the cavity 3 from the feed port and forms a jack or a screw hole. In the above solution, by setting the heating channel 4 on the mold that is isolated from the cavity 3 and at the end of the flow of the liquid material, after the liquid material is injected into the cavity 3 for molding, the heating medium is injected into the heating channel 4 to ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com