Embossed PET (Polyethylene Terephthalate) laminated colorful steel plate and production method thereof

A production method and technology for color steel plates, applied in the field of metal plates, can solve the problems of high cost and poor environmental protection performance of color steel plates, and achieve the effect of solving high costs, improving metal texture and improving profitability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0035] The present invention proposes a new substitute for the current color steel plate. The composite film of the present invention directly uses embossed PET composite color film to replace the current aluminum foil color film or PET+PVC laminated color film. The structure of the PET composite color film: the color layer is on the bottom of the PET film, and the pattern layer is pressed on the top.

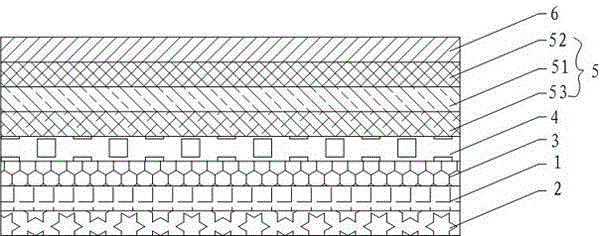

[0036] refer to figure 1 In the cross-sectional structure of the color steel plate shown, the structure from top to bottom is: protective film 6, pattern layer 52, PET film 51, color layer 53, glue layer 4, chemical treatment layer 3, substrate 1, back paint 2. The substrate 1 is a stainless steel plate. The pattern layer 52, the PET film 51 and the color layer 53 constitute the embossed PET composite color film 5. By rolling the pat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com