Anti-sliding and anti-piercing metallic thin film and preparation method thereof

A metal texture and thin film technology, which is applied in chemical instruments and methods, metal material coating technology, flat products, etc., can solve problems such as the lack of metal texture on the surface of the film, poor performance of plastic films, and rougher surface effects of products, etc. , to achieve the effect of good water permeability and oil resistance, beautiful appearance, and improved anti-puncture strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

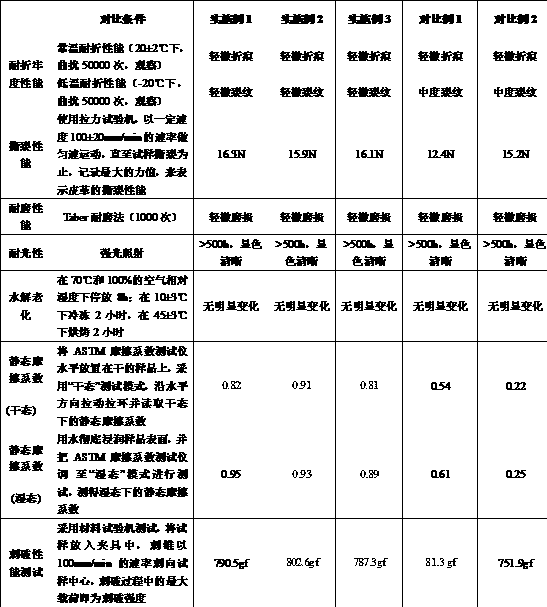

Embodiment 1

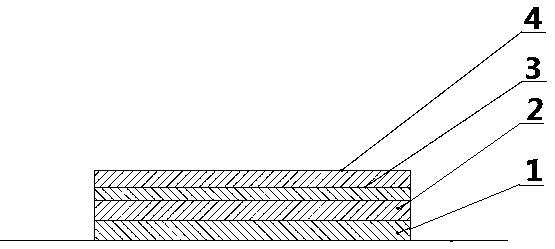

[0031] An anti-slip and anti-puncture metal texture film, which is provided with a coating layer 1, a base layer 2, an anti-slip layer 3 and an anti-puncture layer 4 from bottom to top, the base layer 2 is a PVC film, and the coating layer 1 is formed by non-conductive metal coating A coating layer 1 with a metallic texture is formed on the surface of the base layer, wherein the anti-skid layer 3 is composed of the following components by mass: 35% acrylic resin, 8% tungsten-cobalt alloy sand particles, 4% nano-alumina, styrene isoprene embedded Segment copolymer 10%; anti-puncture layer 4 is composed of the following components in parts by mass: 40% urea-formaldehyde resin, 18% epoxy resin, 2% mixture of sodium polyacrylate and polyethylene oxide, 5% talcum powder, silicon carbide Granules (particle size 100μm) 20%, anhydrous cyclohexanone 4%, titanium dioxide 6%.

[0032] The preparation method of the anti-slip and anti-puncture metal texture film is as follows:

[0033] A....

Embodiment 2

[0038]A non-slip and anti-puncture metal texture film, which is provided with a coating layer 1, a base layer 2, an anti-slip layer 3 and an anti-puncture layer 4 from bottom to top, the base layer 2 is a PET film layer, and the coating layer 1 is formed by non-conductive metal coating. A coating layer 1 with a metallic texture is formed on the surface of the base layer, wherein: the anti-slip layer 3 is composed of the following components by mass: 40% acrylic resin, 9% tungsten-cobalt alloy sand particles, 6% nano-alumina, styrene isoprene Block copolymer 15%; anti-puncture layer 4 is composed of the following components in parts by mass: 50% melamine formaldehyde resin, 20% epoxy resin, 2.5% mixture of sodium polyacrylate and polyethylene oxide, 6% talcum powder, Silicon carbide particles (particle size 110μm) 22%, anhydrous cyclohexanone 5%, titanium dioxide 7%.

[0039] The preparation method of the anti-slip and anti-puncture metal texture film is as follows:

[0040] A...

Embodiment 3

[0045] A non-slip and anti-puncture metal texture film, which is provided with a coating layer 1, a base layer 2, an anti-slip layer 3 and an anti-puncture layer 4 from bottom to top, the base layer 2 is a PVC film layer, and the coating layer 1 is formed by non-conductive metal coating. A coating layer 1 with a metallic texture is formed on the surface of the base layer, wherein: the anti-slip layer 3 is composed of the following components by mass: 45% acrylic resin, 10% tungsten-cobalt alloy sand particles, 8% nano-alumina, styrene isoprene Block copolymer 20%; puncture-resistant layer 4 is composed of the following components in parts by mass: polyamide polyamine epichlorohydrin 60%, epoxy resin 25%, a mixture of sodium polyacrylate and polyethylene oxide 3%, Talc powder 7%, silicon carbide particles (particle size 120μm) 25%, anhydrous cyclohexanone 6%, titanium dioxide 9%.

[0046] The preparation method of the anti-slip and anti-puncture metal texture film is as follows...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com